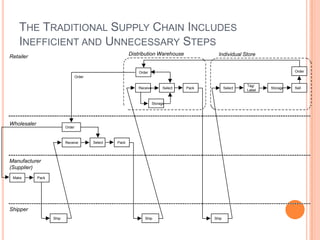

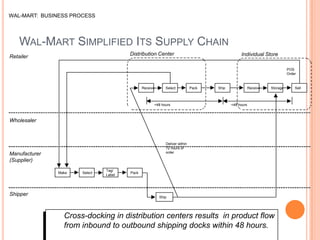

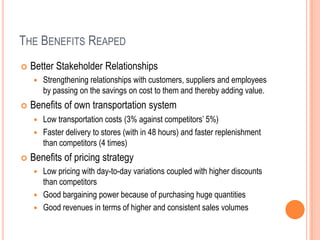

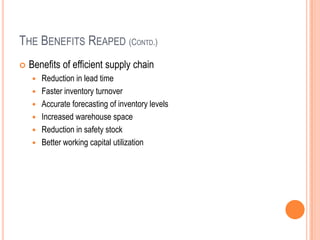

Walmart has one of the largest and most efficient supply chain networks in the world. It simplified its supply chain by eliminating unnecessary middlemen and implementing cross-docking so products flow directly from manufacturers to stores within 48 hours. Walmart also heavily invests in inventory management technology to track sales and replenish stores quickly. This allows it to keep inventory levels low while maintaining high product availability.