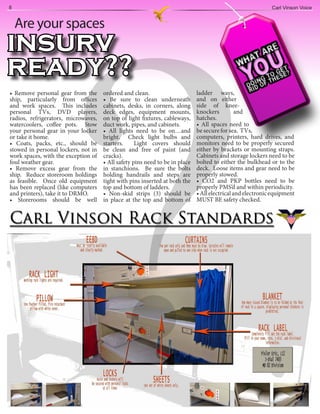

The Carl Vinson crew is preparing for their upcoming INSURV inspection by thoroughly cleaning and organizing all spaces on the ship. Sailors are removing personal items, deep cleaning areas like equipment mounts and ductwork, ensuring all lights are bright and in working order, and securing loose gear. Proper preparation requires attention to details from non-skid strips to safety checks on electrical equipment to pass the inspection. Teamwork across departments will be necessary to get the entire ship up to standards.

![6 Carl Vinson Voice

Sailor

SPOTLIGHT

IN THE

Story by MC3 Shentel Downes

USS Carl Vinson Staff Writer

She manages $850,000 in continuing years and on board 10 months. Although

Logistics Specialist 2 Class nd

services, $135,000 in contracts through she has sacrificed a lot personally to do

(AW/SW) Maggie Applewhite’s can- the Federal Industrial Supply Center, well professionally, Applewhite has a

do attitude and desire to succeed and $2.9 million in credit card purchases strong sense of purpose in her work.

have set the standard for excellence in with zero discrepancies. “Being away does have its trying

Supply Department S-1 Division, Stock Applewhite’s positive attitude times because I do miss my daughter.

Control. has gained the respect of Logistics I have missed her first steps, her first

A native of San Diego, Specialist 1st Class (SW/AW) Martha words, and different milestones in her

Applewhite balances her duties as Maya, S-1 Division assistant leading life,” said Applewhite. “None of that can

Sailor a with her responsibilities as a petty officer. be brought back, but I do know that in

single parent. “She never says no,” said Maya. the end, I’m doing what I have to do

“It does get hard being in “She’ll do anything you ask of her. now to provide for her. When I reach

the Navy as a single parent,” said Even during closeouts, she tries to help my 20-year mark, my daughter will be

Applewhite. “But when it becomes too customers who come to the door. She’s of age to look back and say ‘I remember

much for me, I look at [my daughter’s] not afraid to take on a challenge. Her when mommy was gone to defend our

picture and tell myself that things won’t motivation isn’t just to be seen, but to country’.”

stay the same forever and to keep the be involved and help people out.” Applewhite is currently working

press on.” Applewhite is the training petty toward a bachelor’s degree in human

Applewhite is a government- officer for the division and a member resources. She plans to retire from the

credit-card holder and customer of the Second Class Petty Officers’ Navy as a Chief Petty Officer and own

service supervisor in S-1 Division. Association. She has been in the Navy 11 her own business.

Photo by MC3 Shentel Downes](https://image.slidesharecdn.com/voiceoct6-101008124452-phpapp01/85/Voice-oct-6-6-320.jpg)

![October 7, 2010 7

Photo by MC3 Aaron Shelley

From`INSURV` page 1

affects someone else on the ship,” said

Young. “If Engineering doesn’t do their

job, Air Department can’t do theirs, and it

goes on and on. There’s no ‘i’ in ‘team’, but

there’s an ‘m’ and an ‘e’. It’s up to us to ask,

‘what can I do to improve this team?’”

Answering that question involves

taking initiative and stepping up when

you see something is wrong.

“This ship is over two decades old.

If something is going to break, it’s not just

going to break. There will be signs leading

up to it, like unusual noises or leaking

fluids. It’s up to each of us to report it if it

doesn’t look right,” said Logistics Specialist

3rd Class (SW/AW) Jonathan Gayles.

Chief Mass Communication

Specialist (AW) Daniel Wolsey, Training

Department’s Leading Chief Petty Officer,

said he’s seen more Sailors stepping up

to do just that, but there is still room for

improvement.

“[Sailors] have to believe in the

Photo by MC3 Heather Roe

ship and take ownership,” said Wolsey.

“Once they do, they’ll take better care of

the ship and its equipment.”

Fire Controlman 1st Class (SW/

AW) Ernest Peebles commented on the

reason why ownership should be in the

forefront of the minds of every Vinson

Sailor.

“We will all fail if we don’t take

ownership. We have to do our best to fix

what problems we have, or else we will fail,”

said Peebles. “It’s one team, one fight.”](https://image.slidesharecdn.com/voiceoct6-101008124452-phpapp01/85/Voice-oct-6-7-320.jpg)