Water Use and Intensity Analysis for Oil and Gas Development

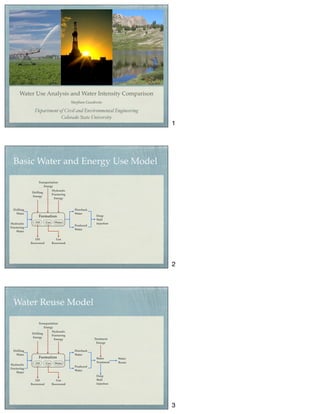

- 1. Water Use Analysis and Water Intensity Comparison Stephen Goodwin Department of Civil and Environmental Engineering Colorado State University Basic Water and Energy Use Model Formation Oil Gas Water Drilling Water Hydraulic Fracturing Water Flowback Water Produced Water Deep Well Injection Oil Recovered Gas Recovered Drilling Energy Hydrualic Fracturing Energy Transportation Energy Water Reuse Model Water Treatment Drilling Water Hydraulic Fracturing Water Flowback Water Produced Water Formation Oil Gas Water Drilling Energy Hydrualic Fracturing Energy Oil Recovered Gas Recovered Transportation Energy Deep Well Injection Water Reuse Treatment Energy 1 2 3

- 2. Water Intensity Drilling Water Hydraulic Fracturing Water Flowback Water Produced Water Formation Oil Gas Water Deep Well Injection Drilling Energy Hydrualic Fracturing Energy Oil Recovered Gas Recovered Water Treatment Water Reuse Treatment Energy Water Intensity Transportation Energy Water Intensity Net Water Consumed (Gallons) Net Energy Recovered (MMBtu) = Reducing Water Intensity Optimize water management with transportation, piping, and locating permanent and mobile treatment facility. (Ashwin Dhanasekar) Temporal and spatial characterization of flowback and produced water quality and volumes to determine what water can be treated. (Bing Bai) Optimize treatment approaches and dilution with modeling and bench-scale testing. (Ryan Hutcherson and Nasim Esmaeilirad) Reduce water use for drilling and hydraulic fracturing Reduce energy use for drilling and hydraulic fracturing Increase energy recovery CSU’s Center for Energy Water Sustainability Research Other Possibilities Indirectly Addressed by CSU Research How much water is required to drill and hydraulically fracture a well in Northern Colorado? 4 5 6

- 3. Water Use: Sampling WELD LARIMER ADAMS MORGAN BOULDER ARAPAHOE JEFFERSON GILPIN DENVER CLEAR CREEK GRAND BROOMFIELD Legend Extended horizontal wells sampled Horizontal wells sampled Vertical wells sampled Wattenberg Field (as defined by the COGCC on July 1, 2013) WELD LARIMER ADAMS MORGAN BOULDER ARAPAHOE JEFFERSON GILPIN DENVER CLEAR CREEK GRAND BROOMFIELD Legend Extended horizontal wells sampled Horizontal wells sampled Vertical wells sampled Wattenberg Field (as defined by the COGCC on July 1, 2013) ADAMS MORGAN BOULDER ARAPAHOE JEFFERSON GILPIN DENVER CLEAR CREEK GRAND BROOMFIELD Legend Extended horizontal wells sampled Horizontal wells sampled Vertical wells sampled Wattenberg Field (as defined by the COGCC on July 1, 2013) ADAMS MORGAN BOULDER ARAPAHOE JEFFERSON GILPIN DENVER CLEAR CREEK GRAND BROOMFIELD Legend Extended horizontal wells sampled Horizontal wells sampled Vertical wells sampled Wattenberg Field (as defined by the COGCC on July 1, 2013) decisions regarding future water and energy development. The objective of this study is to provide a detailed assessment of current water use and to determine the factors that have the strongest influence on the total water use per well. These factors include the well type (vertical, horizontal, or extended horizon- tal), number of hydraulic fracturing stages, water use (drilling or hydraulic fracturing), temporal, and spatial distribution. 2. Method The wells included in the water use analysis are limited to wells located in the Wattenberg field, drilled between January 1, 2010 to July 1, 2013, and operated by Noble Energy, Inc. (Noble) with complete water use records available. For this study, the Wattenberg field is defined by the Colorado Oil Gas Conservation Commission’s (COGCC) GIS shape file accessed on July 1, 2013 (Figure 1). To best assess current water require- ments and predict future demands only wells drilled after 2010 are included in the study. Noble is the largest operator in the Wattenberg field. WELD LARIMER ADAMS MORGAN BOULDER ARAPAHOE JEFFERSON GILPIN DENVER CLEAR CREEK GRAND BROOMFIELD Legend Extended horizontal wells sampled Horizontal wells sampled Vertical wells sampled Wattenberg Field (as defined by the COGCC on July 1, 2013) WELD LARIMER ADAMS MORGAN BOULDER ARAPAHOE JEFFERSON GILPIN DENVER CLEAR CREEK GRAND BROOMFIELD Legend Extended horizontal wells sampled Horizontal wells sampled Vertical wells sampled Wattenberg Field (as defined by the COGCC on July 1, 2013) Figure 1: The spatial distribution of sampled wells used in this study. Sampled vertical wells are shown in green, sampled horizontal wells are shown in blue, and extended horizontal wells are shown in red. The Wattenberg field as defined by the COGCC on July 1, 2013 is shown in tan. A total of 1,227 wells are included (Table 1) and categorized using: A) drilling water consumed; B) hydraulic water con- sumed; C) total water consumed; D) well type (vertical, hor- izontal, or extended horizontal); E) hydraulic fracturing stages or distance; F) hydraulic fracturing fluid; G) well coordinates; H) year; and I) target formation, if available. Water use is categorized as either drilling or hydraulic frac- turing water. Water used to drill the well, prepare the borehole, Table 1: The count of sampled wells separated by year and well type. Vertical Horizontal Extended horizontal 2010 181 6 0 2011 408 69 0 2012 227 196 2 2013 5 120 13 Total 821 391 15 and set the casings is defined as drilling water. Water used to fracture the shale, carry the proppant, and flush the well is de- fined as hydraulic fracturing water. Drilling and hydraulic fracturing water consumption records for each well are collected using Noble Energy’s WellView software [9] and separated by year. WellView is part of the Peloton suite of software used for collecting and organizing oil field data. Drilling and hydraulic fracturing reports are added to WellView by a Noble employee that is on-location at each drilling and hydraulic fracturing site. The water consumption totals are verified by Noble Energy’s accounting department and any conflict of values between the field operations and the accounting department are reconciled in WellView. The wa- ter use data was downloaded from Noble Energy’s WellView software on July 1, 2013. The drilling and hydraulic fracturing water use are summed, if both are available, to estimate the total water consumed. Wells are by separated by type (vertical, horizontal, or ex- tended horizontal) using Noble’s well naming system or the number of hydraulic fracturing stages, if available. Directional and deviated wells are categorized as vertical wells for this study because of similar water requirements. Horizontal wells are separated from extended horizontal wells by Noble’s well naming system or the number of hydraulic fracturing stages used when available. A horizontal well will typically be hy- draulically fractured in 20 stages. Recently, Noble has drilled and hydraulically fractured longer horizontal wells that can in- clude over 40 stages to hydraulically fracture. Horizontal wells that require over 30 hydraulic fracturing stages are defined as as extended horizontal wells in this study. The type of hydraulic fracturing fluid used and the number of hydraulic fracturing stages per well are collected from No- ble Energy’s WellView software. The well coordinates, year, and target formation are all collected COGCC’s online facili- ties database. An Anderson-Darling test [10] is used to test the normality of each subset of data. The di↵erence between water use for each subset of data is tested using a nonparametric Kruskal- Wallis test. A Dunn- ˘Sid´ak post-hoc comparison [11] is used to compare any di↵erences between samples that are found us- ing the Kruskal-Wallis test. A 95% confidence interval is used throughout the analysis. The number of hydraulic fracturing stages is correlated using a simple linear regression. A coef- ficient of determination is used to measure how well the re- gression correlates the hydraulic fracturing water use and the number of stages. Spatial autocorrelations are measured with ArcGIS Spatial Analyst tool [12] using Moran’s I with inverse 2 0 2 4 6 8 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 Water use (million gallons) Density Total water use by well type Vertical wells Horizontal wells Extended horizontal wellsdistance weighting and a 95% confidence interval. 942 wells have both drilling or hydraulic fracturing water and are included in the study. Wells that are drilled but not hydraulically fractured (260 sampled wells) are typically con- ventional wells recovering from an oil and gas trap. Wells that are hydraulically fractured but not drilled (25 sampled wells) are typically existing wells that are reworked or restimulated using hydraulic fracturing. 3. Results A Kruskal-Wallis test reveals there is a significant di↵er- ence between the median total water use for vertical, horizon- tal, and extended horizontal wells ( 2 (2)=609, p<0.05). Dunn- ˘Sid´ak post-hoc comparisons of the total water for the three well groups indicates that vertical wells (Mdn=360,000) use signif- icantly less total water than either horizontal (Mdn=2,891,000) or extended horizontal wells (Mdn=6,578,000). There is not a significant di↵erence between the total water use between hor- izontal and extended horizontal wells. 0 2 4 6 8 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 Water use (million gallons) Density Total water use by well type Vertical wells Horizontal wells Extended horizontal wells Figure 2: The distribution of drilling and hydraulic fracturing water use for ver- tical, horizontal, and extended horizontal wells is illustrated with a histogram. Vertical wells are shown in green, horizontal wells are shown in blue, and ex- tended horizontal wells are shown in red. Table 2: Descriptive statistics for total water use separated by well type. Total Vertical Horizontal Extended horizontal Q1 332,900 2,607,000 6,391,000 Q2 360,000 2,891,000 6,578,000 Q3 462,900 3,168,000 7,096,000 IQR 129,000 561,600 704,800 Skewness 9.1 2.9 -2.0 Kurtosis 99 20 5.0 Hydraulic fracturing uses the majority of the total water for all of the well types. For vertical wells, a median value of 81% (Q1=77%, Q3=85%) of the total water is used for hydraulic fracturing. Horizontal and extended horizontal wells use a me- dian value of 96% (Q1=95%, Q3=96%) and 98% (Q1=97%, Q3=98%) for hydraulic fracturing, respectively. The total water use for horizontal and extended horizon- tal wells correlates (r2 =0.66) to the number of stages used to hydraulically fracture each well (Figure 3). Wells defined as horizontal wells (less than 30 stages) are shown in blue re- gion and the wells defined as extended horizontal wells are shown in the red region. A linear regression using a least- squares linear fit is shown as a red line (Total water use in gal- lons=156,000x(Number of stages)-144,000). 5 10 15 20 25 30 35 40 45 0 1 2 3 4 5 6 7 8 Number of hydraulic fracturing stages Hydraulicfracturingwateruse(millionsofgallons) Horizontal wells Extended horizontal wells Figure 3: A simple linear regression between the number of hydraulic fracturing stages and the volume of hydraulic fracturing water used is shown with the red line. Horizontal wells (less than 30 stages) are shown in the blue region and extended horizontal wells are shown in the red region. When the total water use for horizontal and extended hor- izontal wells are normalized to the number of hydraulic frac- turing stages, the distribution of the total water per hydraulic fracturing stage is similar (Figure 4). When vertical wells are normalized to the vertical distance of the hydraulic fracturing there is not a correlation between the total water use (r2 =0.081) or hydraulic fracturing water use (r2 =0.073). Vertical wells are significantly influenced by the type of hy- draulic fracturing fluid used. The normalized hydraulic fractur- ing water use is significantly less for gelled fractures (Mdn=544 gallons per foot) than slickwater fractures (Mdn=1,340 gallons per foot) for vertical wells ( 2 (1)=42.4, p<0.05). Horizontal wells do not have enough slickwater data to compare gelled and slickwater hydraulic fracturing water use. Only the total water use for vertical wells shows any sig- nificant temporal variation ( 2 (3)=13.09, p<0.05) . The to- tal water use for vertical wells has decreased slightly from 2011 (Mdn=362,000) to 2012 (Mdn=352,000). Horizontal ( 2 (3)=6.03, p=.01103) or extended horizontal ( 2 (3)=2.45, p=0.117) wells do not show any significant temporal variation. The spatial distribution of the total water use is shown in Fig- ure 6. Vertical wells are shown in green, horizontal wells are 3 Water Use0 1 2 3 4 5 6 7 8 Wateruse(milliongallons) Drilling and hydraulic fracturing water by well type Drilling Hydraulic fracturing Drilling Hydraulic fracturing Drilling Hydraulic fracturing Vertical wells Horizontal wells Extended horiozontal wells Figure 7: The distribution of drilling and hydraulic fracturing water use for vertical, horizontal, and extended horizontal wells. The interquartile range is defined by the blue box, the median is defined by the red line, and outliers extending beyond the 10th and 90th percentile are shown with red pluses. Table 3: Descriptive statistics for drilling and hydraulic fracturing water use separated by well type. Drilling Vertical Horizontal Extended horizontal Q1 62,160 94,500 148,300 Q2 74,760 116,300 180,800 Q3 89,040 140,700 202,300 IQR 26,880 46,240 54,020 Skewness 12 0.97 0.40 Kurtosis 240 2.3 0.54 Hydraulic Vertical Horizontal Extended horizontal Fracturing Q1 269,400 2,490,000 6,127,000 Q2 278,900 2,792,000 6,517,000 Q3 395,000 3,033,000 6,883,000 IQR 125,700 543,000 757,300 Skewness 9.2 2.9 -2.1 Kurtosis 100 20 5.3 continue to in the future Table 1. The number of hydraulic fracturing stages should be the pri- mary consideration when estimating the total water use of hor- ter has remained constant or decreased slightly since 2010 for both vertical and horizontal wells. The majority of wells target the Niobrara formation and several vertical wells target multiple formations including the Niobrara. The water use is not statis- tically significant between target formations. Significant spatial autocorrelations do not show any obvious spatial patterns. The type of hydraulic fracturing fluid influences the volume of water required to hydraulically fracture a vertical well. Hy- draulic fracturing with slickwater requires nearly two times the water per hydraulic fracturing distance than using gelled fluids. It is also important to consider the volume of oil and gas recovered for each well type when comparing the total water use. Water use is often normalized to the amount of energy recovered with the water and is defined as the water intensity. This measure is an important value to consider for best water management practices. Although extended horizontal wells use the most water, it is likely they also recover much more oil and gas. An analysis of the water intensity for each well in the future will be important to optimizing water management. This study did not include flowback or produced water es- timates for each well. Flowback is the water that returns to the surface before production. This water is characterized by high solids content and closely resembles the hydraulic frac- turing fluid. Produced water is the water that returns with the oil and gas. This water is characterized by high concentrations of salts and closely resembles the formation water. E↵orts are being made to treat and reuse this water and further reduce the demands on water resources. As water reuse becomes more prevalent in the Wattenberg field, the net water use should be considered. The majority of the total water use for horizontal and ex- tended horizontal wells consists of hydraulic fracturing water. This results in large volumes of flowback water from horizon- tal and extended horizontal wells. The impact of water reuse for these wells becomes much more considerable than with vertical wells. 5. Conclusions As horizontal wells become more prevalent in the future, wa- ter demand predictions should be based on the number of hy- draulic fracturing stages rather than the number of wells. The number of hydraulic fracturing stages can range from three to 45 and the total water use can vary from a few hundred thou- sand gallons up to nearly eight million gallons per well. It is a mistake to simply assume that all of the wells use a specific volume of water, particularly as the lateral lengths of horizon- tal wells are becoming longer to minimize surface impacts and 0 1 2 3 4 5 6 7 8 Wateruse(milliongallons) Drilling and hydraulic fracturing water by well type Drilling Hydraulic fracturing Drilling Hydraulic fracturing Drilling Hydraulic fracturing Vertical wells Horizontal wells Extended horiozontal wells 7 8 9

- 4. Spatial Distribution of Water Use 1Q: Horizontal wells 2Q: Horizontal wells 3Q: Horizontal wells 4Q: Horizontal wells 1Q: Vertical wells 2Q: Vertical wells 3Q: Vertical wells 4Q: Vertical wells 1Q: Extended horizontal wells 2Q: Extended horizontal wells 3Q: Extended horizontal wells 4Q: Extended horizontal wells Spatial Autocorrelation Spatially autocorrelated horizontal wells Spatially autocorrelated vertical wells Moran’s I used at 95 percent confidence interval with inverse distance weighting Total Water Use by Year 0 1 2 3 4 5 6 7 8 2010 2011 2012 2013 Vertical wells Totalwateruse(milliongallons) 0 1 2 3 4 5 6 7 8 2010 2011 2012 2013 Horizontal wells 10 11 12

- 5. Water Use by Year 0 0.1 0.2 0.3 0.4 0.5 2010 2011 2012 2013 Drilling water Vertical wells Wateruse(milliongallons) 0 2 4 6 8 10 2010 2011 2012 2013 Hydraulic fracturing water Vertical wells 0 0.1 0.2 0.3 0.4 0.5 2010 2011 2012 2013 Drilling water Horizontal wells Wateruse(milliongallons) 0 2 4 6 8 10 2010 2011 2012 2013 Hydraulic fracturing water Horizontal wells 0 0.1 0.2 0.3 0.4 0.5 2010 2011 2012 2013 Drilling water Horizontal wells Wateruse(milliongallons) 0 2 4 6 8 10 2010 2011 2012 2013 Hydraulic fracturing water Horizontal wells Total Water Use Normalized by the Number of Hydraulic Fracturing Stages 5 10 15 20 25 30 35 40 45 0 1 2 3 4 5 6 7 8 Number of hydraulic fracturing stages Hydraulicfracturingwateruse(millionsofgallons) Horizontal wells Extended horizontal wells r2=0.66 Total Water Use Normalized by the Number of Hydraulic Fracturing Stages 0 0.1 0.2 0.3 0.4 0 0.2 0.4 Density Ratio of total water use and number of hydraulic fracturing stages Extended horizontal wells 0 0.1 0.2 0.3 0.4 0 0.2 0.4 Total water use per hydraulic fracturing stage (million gallons) Density Horizontal wells 13 14 15

- 6. How efficiently is the water used? Water Intensity Drilling Water Hydraulic Fracturing Water Flowback Water Produced Water Formation Oil Gas Water Deep Well Injection Drilling Energy Hydrualic Fracturing Energy Oil Recovered Gas Recovered Water Treatment Water Reuse Treatment Energy Water Intensity Transportation Energy Water Intensity Net Water Consumed (Gallons) Net Energy Recovered (MMBtu) = Water Use per Well (First Study, 2010-2011) ydraulic Fracturing Water Total 0.00672 0.07224 0.0084 0.07392 0.00798 0.07476 0.01722 0.08274 0.0084 0.08484 0.00882 0.0861 0.01176 0.08694 0.00588 0.08694 0.0084 0.08694 0.01302 0.08736 0.0084 0.08736 0.0042 0.0882 0.01932 0.08883 0.00756 0.09072 0.00882 0.09618 0.051492 0.121212 0.057456 0.166026 0.112476 0.169596 0.11655 0.17241 0.11592 0.1911 0.15162 0.20916 0.147042 0.222222 0.156156 0.227976 0.166908 0.232428 0.148218 0.238308 0.155022 0.243852 0.244734 0.290934 0.227724 0.293244 0.11403 0.29463 0.22806 0.29715 0.241458 0.304458 0.271614 0.307314 0.270312 0.307692 0.27594 0.30954 0.251202 0.310632 0.273924 0.312144 0.271026 0.313866 0.250194 0.314454 0.273126 0.314706 0.27972 0.31479 0.275898 0.315588 0.230202 0.315882 0.270312 0.316512 0.267834 0.317814 0.275478 0.319788 0.264138 0.321678 0.2604 0.32256 0.273 0.32256 0.268254 0.322854 0.270186 0.323106 0.274848 0.323988 0.267456 0.326256 0.277872 0.326382 1 2 3 4 5 0 100 200 300 400 WaterConsumption(milliongallons) Noble Well Water Consumption Ranking Horizontal Drilling Water Horizontal Hydraulic Fracturing Water Vertical Drilling Water Vertical Hydraulic Fracturing Water (Gallons) Drilling Water Hydraulic Fracturing Water Total Water (Gallons)(Gallons)(Gallons) Horizontal Well Vertical Well 129,000 2,720,000 2,840,000 76,800 305,000 382,000 445 NOBLE WELLS: 386 VERTICAL AND 59 HORIZONTAL 16 17 18

- 7. Water and Energy Consumption 0 0.5 1 1.5 2 2.5 3 3.5 Drilling Water Hydraulic Fracturing Water Total Water WaterConsumed(MMgal) Water Use for Sampled Wells Student Version of MATLAB Water Intensity Drilling Water Hydraulic Fracturing Water Flowback Water Produced Water Formation Oil Gas Water Deep Well Injection Drilling Energy Hydrualic Fracturing Energy Oil Recovered Gas Recovered Water Treatment Water Reuse Treatment Energy Water Intensity Transportation Energy Water Intensity Net Water Consumed (Gallons) Net Energy Recovered (MMBtu) = Estimated Ultimate Recovery 15 20 25 30 35 32640 33290 33670 33910 34090 34220 52340 53630 54360 54850 55190 55450 61720 196880 225980 251270 273890 294490 97020 362300 416330 463290 505280 545550 Gas Production (mcf) 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 0 175310 188140 193510 196580 198610 200060 201160 0 258790 276460 283840 288050 290820 292810 294320 0 583900 833900 1020700 1175400 1309800 1430100 1539700 0 930400 1399700 1754400 2049600 2306800 2537300 2747600 Gas Production (boe) 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 0 29218 31357 32252 32763 33102 33343 33527 0 43132 46077 47307 48008 48470 48802 49053 0 97317 138983 170117 195900 218300 238350 256617 0 155067 233283 292400 341600 384467 422883 457933 15 20 25 30 35 32640 33290 33670 33910 34090 34220 19700 20340 20690 20940 21100 21230 09380 143250 171620 196420 218700 239040 35300 165420 190350 212020 231390 251060 0 100,000 200,000 300,000 0 5 10 15 20 25 30 35 Oil EUR of Sampled Wells EstimatedUltimateRecovery(BOE) Well Lifespan (Years) Gas Production (boe) Sectioned 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 0 29218 31357 32252 32763 33102 33343 33527 0 13913 14720 15055 15245 15368 15458 15527 0 54185 92907 122810 147892 169830 189548 207563 0 57750 94300 122283 145700 166167 184533 201317 0 5 10 15 20 25 30 35 Gas EUR of Sampled Wells Well Lifespan (Years) Percentile Total Energy (BOE) 5th 50th 95th 1945 228 0 g 15 20 25 30 35 3790 3810 3830 3830 3840 3840 8500 8500 8500 8600 8600 8600 69170 83190 94790 104860 113860 120000 05400 367400 418600 463200 503000 539300 15 20 25 30 35 59180 160020 160860 160860 161280 161280 57000 357000 357000 361200 361200 361200 Flowback and Produced (gallons) Sectioned 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 132678 289758 291858 292698 293538 293538 293958 293958 132678 324198 330498 329658 328818 333018 332598 332598 132678 1898778 2680818 3269658 3756858 4175598 4553598 4811478 132678 7346178 10054338 12069498 13732698 15182958 16476558 17743278 Total (MMBtu) 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 0 359981 382443 391732 397090 400568 403102 404986 0 551103 587279 602337 610892 616578 620593 623651 0 1263689 1793659 2189287 2516826 2801435 3056087 3288043 0 2169569 3158467 3901126 4517475 5053820 5533937 5983307 19 20 21

- 8. Estimated Ultimate Water Recovery 30 35 161280 161280 361200 361200 4782120 5040000 21126000 22650600 30 35 161280 161280 199920 199920 4420920 4678800 16343880 17610600 0 1,200,000 2,400,000 3,600,000 4,800,000 6,000,000 0 5 10 15 20 25 30 35 Flowback and Produced Water EUR of Sampled Wells FlowbackandProducedWater(Gallons) Well Lifespan (Years) 25 30 35 2826978 2826558 2826558 2626638 2626638 2626638 -1416282 -1794282 -2052162 -16466562 -18138162 -19662762 25 30 35 3830 3840 3840 8600 8600 8600 104860 113860 120000 463200 503000 539300 25 30 35 160860 161280 161280 361200 361200 361200 4404120 4782120 5040000 19454400 21126000 22650600 25 30 35 2907408 2907198 2907198 2807238 2807238 2807238 785778 596778 467838 -6739362 -7575162 -8337462 Net Water Use (100% reuse) Sectioned 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 2987838 -6340362 -9838962 -12442962 -14593362 -16466562 -18138162 -19662762 2987838 873138 82698 -506142 -993342 -1416282 -1794282 -2052162 2987838 2639238 2630838 2630838 2630838 2626638 2626638 2626638 2987838 2830758 2828658 2827818 2826978 2826978 2826558 2826558 Net Water Use (100% reuse) Sectioned 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 2987838 -6340362 -9838962 -12442962 -14593362 -16466562 -18138162 -19662762 0 7213500 9921660 11936820 13600020 15050280 16343880 17610600 0 1766100 2548140 3136980 3624180 4042920 4420920 4678800 0 191520 197820 196980 196140 200340 199920 199920 0 5 10 15 20 25 30 35 Net Water Use with 100 Percent Reuse Well Lifespan (Years) Net Water Use (50% reuse) Sectioned 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 2987838 -1676262 -3425562 -4727562 -5802762 -6739362 -7575162 -8337462 2987838 1930488 1535268 1240848 997248 785778 596778 467838 2987838 2813538 2809338 2809338 2809338 2807238 2807238 2807238 2987838 2909298 2908248 2907828 2907408 2907408 2907198 2907198 Net Water Use (50% reuse) Sectioned 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 2987838 -1676262 -3425562 -4727562 -5802762 -6739362 -7575162 -8337462 0 3606750 4960830 5968410 6800010 7525140 8171940 8805300 0 883050 1274070 1568490 1812090 2021460 2210460 2339400 0 95760 98910 98490 98070 100170 99960 99960 -3,000,000 -2,250,000 -1,500,000 -750,000 0 750,000 1,500,000 2,250,000 3,000,000 0 5 10 15 20 25 30 35 Net Water Use with 50 Percent Reuse Well Lifespan (Years) 30 35 403102 404986 620593 623651 3056087 3288043 5533937 5983307 30 35 7.4 7.4 4.8 4.8 1.0 0.9 0.5 0.5 30 35 3 3 4 4 0 0 1 0 30 35 1 0 0 0 4 4 3 3 Estimated Water Intensity (0% Water Reuse) Water Intensity (100% Reuse) 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 7.9 7.4 7.2 7.1 7.1 7.0 7.0 4.8 4.5 4.4 4.3 4.3 4.2 4.2 0.7 0.0 -0.2 -0.4 -0.5 -0.6 -0.6 -2.9 -3.1 -3.2 -3.2 -3.3 -3.3 -3.3 Water Intensity (0% Reuse) 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 3 3 3 3 3 3 3 4 4 5 5 5 5 5 4 3 3 3 3 3 3 -3 -3 -3 -3 -3 -3 -3 Water Intensity (0% Reuse) 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 -3 -3 -3 -3 -3 -3 -3 4 3 3 3 3 3 3 4 4 5 5 5 5 5 3 3 3 3 3 3 3 Estimated Water Intensity (100% Water Reuse) Water Neutrality Water Neutrality Water Neutrality Water Neutrality Water Intensity (50% Reuse) 0 5 10 15 20 25 30 35 Low b=0.6 Median b=0.6 Median b=1.8 High b=1.8 8.3 7.6 7.4 7.3 7.3 7.2 7.2 5.4 4.8 4.7 4.6 4.6 4.5 4.5 2.4 1.1 0.7 0.5 0.4 0.3 0.2 1.4 -0.5 -0.9 -1.0 -1.1 -1.2 -1.3 How does the water intensity compare? 0 15 30 45 60 SurfaceMining UndergroundMining U.S.WeightedAverage Preparation Synfuel:CoalGasification Synfuel:FisherTropsch Conventional NorthernColoradoShaleGas(0%Reuse) NorthernColoradoShaleGas(50%Reuse) NorthernColoradoShaleGas(100%Reuse) Preparation Gas-to-Liquids Primary ConventionalFlooding SaudiArabiaAverage OilSands OilShale U.S.On-ShoreAverage EnhancedOilRecovery ConventionalRefining OilShaleProcessing OilSandsProcessing Mining Enrichment Extraction and Processing Water Intensity by Fuel Source ConsumptiveWaterIntensity(gal/MMBtu) 3.5 19 51 1.5 2.9 2.4 1.8 1 42 1.5 14 22 35 39 58 58 10 39 48 3.5 6 Ethanol from Irrigated Corn Extraction: 16,000 Processing: 60 Biodiesel from Soy Extraction: 45,000 Processing: 300 Biodiesel from Rapeseed Extraction: 16,000 Processing: 300 Coal OilNatural Gas Extraction Processing Uranium Extraction Processing Extraction Processing Wind (Turbine) 0 Solar (Photovoltaic) 0 22 23 24

- 9. Water Consumption of Energy Resource Extraction, Processing, and Conversion reserve estimates ranging from 2.1 to 6.7 MMBtu (2.0 to 6.5 BCF) per well, giving a company- wide range of 0.6 to 1.8 gal/MMBtu (See Table 2-2). (Chesapeake Energy 2010) Table 2-2: Estimates of water consumption for different shale plays (Chesapeake Energy 2010) Water consumption per well (million gal) Gas reserves per well Water intensity Shale play Drilling Hydraulic Fracturing Total BCF MMBtu (million) gal/MMBtu Barnett 0.3 3.8 4.1 2.7 2.7 1.5 Fayetteville 0.1 4.0 4.1 2.4 2.5 1.7 Haynesville 0.6 5.0 5.6 6.5 6.7 0.8 Marcellus 0.1 5.5 5.6 4.2 4.3 1.3 Typical min 1.0 3.5 4.5 6.5 6.7 0.6 Typical max 0.1 3.5 3.6 2.0 2.1 1.8 Average 1.3 The estimates are specific to one company’s operations (i.e. Chesapeake Energy) and reflect typical water-intensity across its asset portfolio, not necessarily a representative range of water- intensity for the industry as a whole. But alternative estimates for Marcellus and Barnett provide comfort that the order of magnitude is appropriate, especially in the context of comparable water- intensity of alternative fossil fuels. Marcellus data The U.S. Geological Survey published a factsheet on water issues relating to the Marcellus shale gas developments (Soeder and Kappel 2009), summarized in Table 2-4. The USGS estimates show a similar average water-intensity to the Chesapeake Energy data, at 1.2 and 1.3 gal/MMBtu respectively, albeit with lower water-consumption per well and lower estimated recoverable reserves per well (roughly half the Chesapeake Energy estimates). Table 2-3: USGS estimates for Marcellus shale (2009) Reserves per well (BCF) 2.5 Reserves per well (million MMBtu) 2.6 Hydraulic fracturing (million gal) 3.0 Average (gal/MMBtu) 1.2 The Susquehanna River Basin Commission (SRBC) regulates water access for a significant portion of the Marcellus shale, covering parts of Pennsylvania, New York, and Maryland. The SRBC estimated in January of 2010 that a typical Marcellus shale stimulation uses between four and seven million gal of water over a two to five-day period, with about 15% of the water flowing back to the surface in the first two months (Susquehanna River Basin Commission 2010), comparable to the Chesapeake estimates. However, based on actual data from approximately 200 wells drilled between June 2008 and March 2009, the SRBC estimates that the average well 18 Water Intensity Comparison Source: E. Mielke, L. D. Anadon, and V. Narayanamurti. Water consumption of energy resource extraction, processing, and conversion. Discussion Paper 2010-15, Harvard Kennedy School Belfer Center for Science and International Affairs, 79 JFK Street, Cambridge, MA 02138, October 2010. Water Intensity Comparison Source: Chesapeake Energy. Water use in deep shale gas exploration. Fact Sheet, September 2011. Once-Through Cooling Closed-Loop Cooling Closed-Loop Cooling with Carbon Capture Dry Cooling IGCC: Closed-Loop Cooling IGCC: Closed-Loop Cooling with Carbon Capture IGCC: Wet Tower IGCC: Wet Tower with Carbon Capture Combined-Cycle Gas Turbine: Once- Through Cooling Combined-Cycle Gas Turbine: Closed-Loop Cooling Combined-Cycle Gas Turbine: Closed-Loop Cooling with Carbon Capture Combined-Cycle Gas Turbine: Dry Cooling Combined-Cycle Gas Turbine: Cooling Pond Combined-Cycle Gas Turbine: Wet Tower Combined-Cycle Gas Turbine: Wet Tower with Carbon Capture Once-Through Cooling Closed-Loop Cooling Closed-Loop Cooling with Carbon Capture Dry Cooling Cooling Pond Wet Tower Parabolic Troughs: Wet Cooling Parabolic Troughs: Dry Cooling Tower: Wet Cooling U.S. Weighted Average of Large-Scale Concentrating Solar Power Dish: Stirling Cycle Photovoltaics Concentrated Solar Photovoltaics Wind 315 405 420 15 369 330 760 500 115 195 190 15 240 130 500 415 575 590 15 680 850 910 80 820 800 10 2 2 0 0 250 500 750 1000 Once-ThroughCooling Closed-LoopCooling Closed-LoopCoolingwithCarbonCapture DryCooling IGCC:Closed-LoopCooling IGCC:Closed-LoopCoolingwithCarbonCapture IGCC:WetTower IGCC:WetTowerwithCarbonCapture Combined-CycleGasTurbine:Once-ThroughCooling Combined-CycleGasTurbine:Closed-LoopCooling Combined-CycleGasTurbine:Closed-LoopCoolingwithCarbonCapture Combined-CycleGasTurbine:DryCooling Combined-CycleGasTurbine:CoolingPond Combined-CycleGasTurbine:WetTower Combined-CycleGasTurbine:WetTowerwithCarbonCapture Once-ThroughCooling Closed-LoopCooling Closed-LoopCoolingwithCarbonCapture DryCooling CoolingPond WetTower ParabolicTroughs:WetCooling ParabolicTroughs:DryCooling Tower:WetCooling U.S.WeightedAverageofLarge-ScaleConcentratingSolarPower Dish:StirlingCycle Photovoltaics ConcentratedSolarPhotovoltaics Wind Electricity Generation Water Intensity by Fuel Source ConsumptiveWaterIntensity(gal/MWh) Coal Natural Gas Uranium Solar Wind Geothermal Electricity Generation: 3,600 Hydropower Electricity Generation: 4,500 25 26 27

- 10. Once-Through Cooling Closed-Loop Cooling Closed-Loop Cooling with Carbon Capture Dry Cooling IGCC: Closed-Loop Cooling IGCC: Closed-Loop Cooling with Carbon Capture IGCC: Wet Tower IGCC: Wet Tower with Carbon Capture Combined-Cycle Gas Turbine: Once- Through Cooling Combined-Cycle Gas Turbine: Closed-Loop Cooling Combined-Cycle Gas Turbine: Closed-Loop Cooling with Carbon Capture Combined-Cycle Gas Turbine: Dry Cooling Combined-Cycle Gas Turbine: Cooling Pond Combined-Cycle Gas Turbine: Wet Tower Combined-Cycle Gas Turbine: Wet Tower with Carbon Capture Once-Through Cooling Closed-Loop Cooling Closed-Loop Cooling with Carbon Capture Dry Cooling Cooling Pond Wet Tower Parabolic Troughs: Wet Cooling Parabolic Troughs: Dry Cooling Tower: Wet Cooling U.S. Weighted Average of Large-Scale Concentrating Solar Power Dish: Stirling Cycle Photovoltaics Concentrated Solar Photovoltaics Wind 35030 480 420 30 389 376 750 620 13780 260 217 30 150 560 42530 830 590 30 800 950 910 80 820 800 10 2 2 0 0 12500 25000 37500 50000 Once-ThroughCooling Closed-LoopCooling Closed-LoopCoolingwithCarbonCapture DryCooling IGCC:Closed-LoopCooling IGCC:Closed-LoopCoolingwithCarbonCapture IGCC:WetTower IGCC:WetTowerwithCarbonCapture Combined-CycleGasTurbine:Once-ThroughCooling Combined-CycleGasTurbine:Closed-LoopCooling Combined-CycleGasTurbine:Closed-LoopCoolingwithCarbonCapture Combined-CycleGasTurbine:DryCooling Combined-CycleGasTurbine:CoolingPond Combined-CycleGasTurbine:WetTower Combined-CycleGasTurbine:WetTowerwithCarbonCapture Once-ThroughCooling Closed-LoopCooling Closed-LoopCoolingwithCarbonCapture DryCooling CoolingPond WetTower ParabolicTroughs:WetCooling ParabolicTroughs:DryCooling Tower:WetCooling U.S.WeightedAverageofLarge-ScaleConcentratingSolarPower Dish:StirlingCycle Photovoltaics ConcentratedSolarPhotovoltaics Wind Electricity Generation Water Intensity by Fuel Source WithdrawnWaterIntensity(gal/MWh) Coal Natural Gas Uranium Solar Wind Geothermal Electricity Generation: 3,600 els 1.5 25 0 12.5 25 37.5 50 ElectricVehicle(PHEV/EV):WindanPhotovoltaic BiodieselfromNonirrigatedSoybeans CNGusingNaturalGasforCompression HydrogenFuelCellwithElectrolysisviaWindandPhotovoltaic HydrogenfromNaturalGas CNGusingElectricityforCompression Diesel Gasoline ElectricVehicle(PHEV/EV):U.S.Grid Plug-InHybridElectricVehicle EthanolfromNonirrigatedCorn OilShaleGasoline SynDieselfromNaturalGas ElectricVehicle OilShaleGasoline HydrogenFuelCellwithElectrolysisviaU.S.Grid SynDieselfromCoal HydrogenviaElectrolysis Coal Oil Natural Gas Solar and Wind Biofuels ConsumptiveWaterIntensity(gallonsper100milesdriven) Water Intensity of Transportation Carey W. King and Michael E. Webber Environmental Science and Tehcnology 2008 42 (21), 7866-7872 Stephen Goodwin stephen.goodwin@colostate.edu Department of Civil and Environmental Engineering Colorado State University cewc.colostate.edu Questions? 28 29 30