The document outlines the structure and functionality of global master data (GMD) and its components, including structural, behavioral, and relational objects tailored for platform users. It details how users can create virtual enterprise models (VEM) and input models, including steps for defining objects, attributes, hierarchies, and constraints, culminating in problem and solution models for optimization purposes. The document emphasizes the reusability of templates and the organization of data for effective problem-solving and reporting across various platform elements.

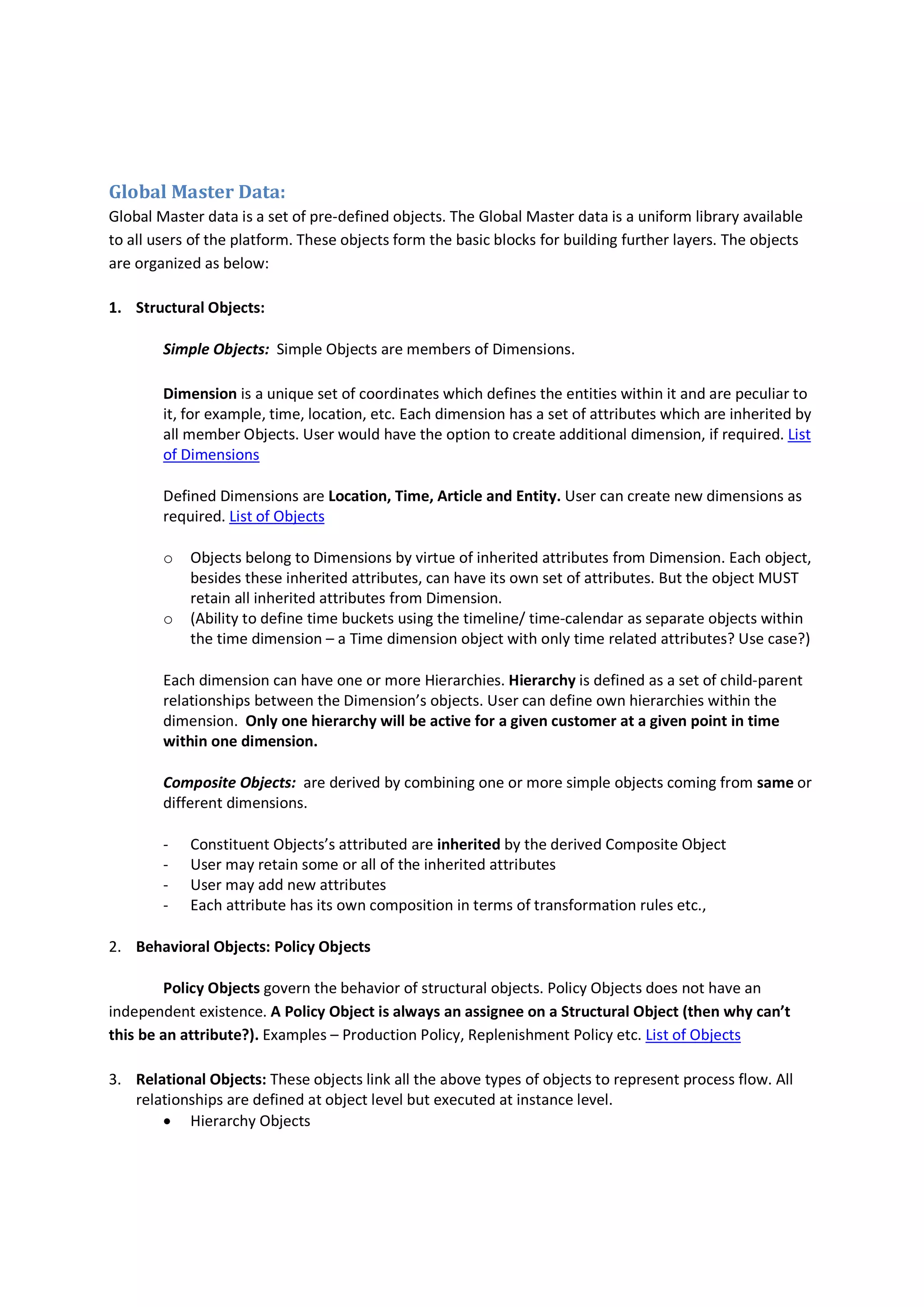

![31-08-2010 Private and Confidential 22

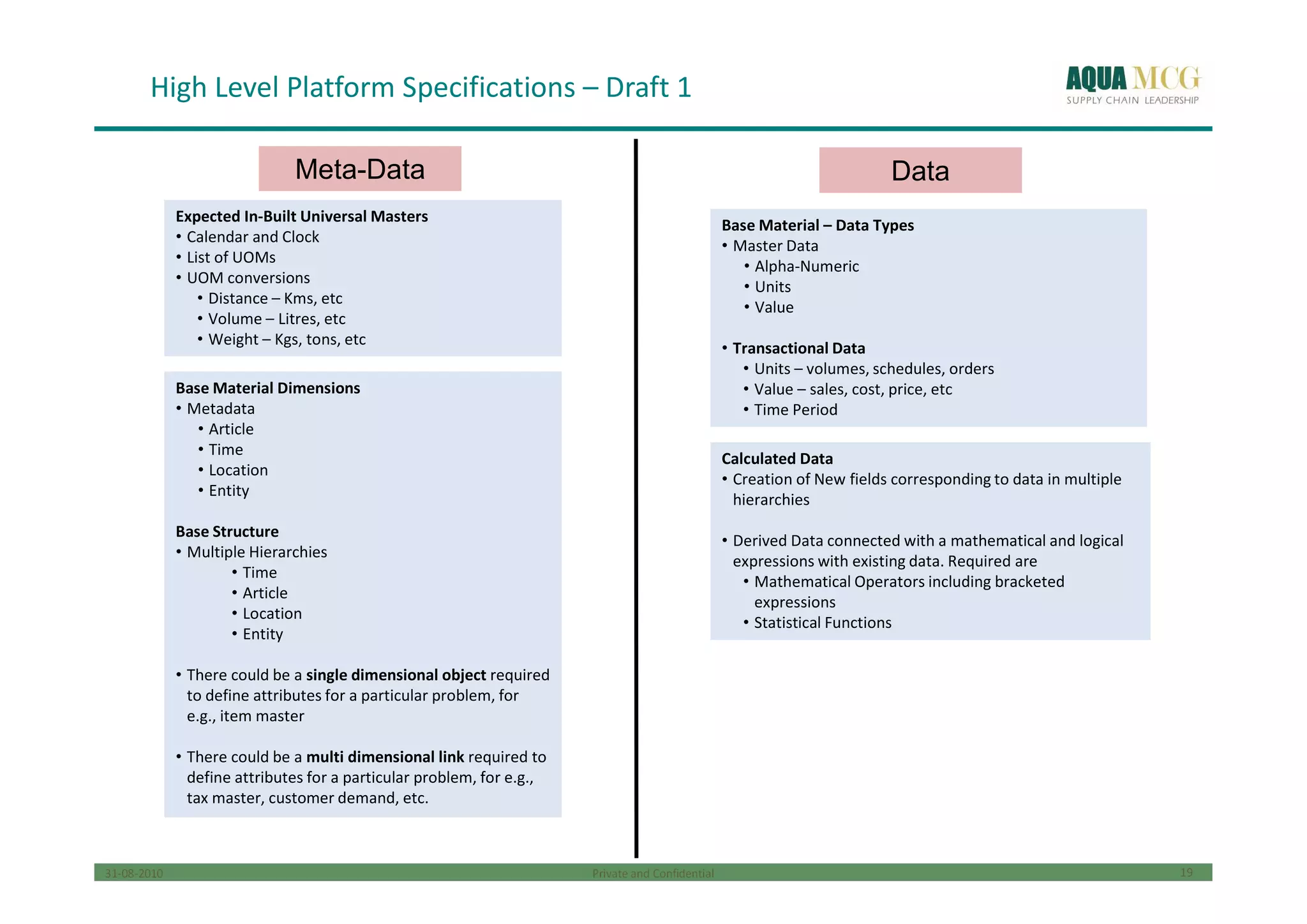

Platform – Derived Data

Functionality to create New Data and Define it using a mathematical or logical relationship with existing data.Functionality to create New Data and Define it using a mathematical or logical relationship with existing data.

Use Case 1

Formula within time

periods

Use Case 1

Formula within time

periods

Use Case 2

Formulae across

time periods

Use Case 2

Formulae across

time periods

Functionality Required:

• Pallet to choose data type and field and to choose mathematical / logical operators to build a formula linking the data

• Data should show the relative time period in brackets only in case the formula is across time periods

• Data should show the entire list of fields upon clicking on the data type

• UOM of the data should appear upon taking the pointer above the data field

• Saving of Several Versions of the Same Data based on Planning Cycle Month should be possible for some data

• Data Formula applicability for Past, Current or Future Time Periods or a combination of 2 or more

Functionality Required:

• Pallet to choose data type and field and to choose mathematical / logical operators to build a formula linking the data

• Data should show the relative time period in brackets only in case the formula is across time periods

• Data should show the entire list of fields upon clicking on the data type

• UOM of the data should appear upon taking the pointer above the data field

• Saving of Several Versions of the Same Data based on Planning Cycle Month should be possible for some data

• Data Formula applicability for Past, Current or Future Time Periods or a combination of 2 or more

Data Types

Equation Constructs

Sales

Stock

Forecasts

Purchase

Orders

Transfer

Orders

Receipts

Requisitions

LHS Data

Field

Use Case 3

Formulae across

planning cycles

Use Case 3

Formulae across

planning cycles

Sales Value

Sales Volume Unit Price

% Sales

Increase Sales (0)( ) /

% Absolute

Forecast

Error

Forecast [-1]

Sales

Volume (0)

ABS ( )/

Sales (-1) Sales (0)

Use Case 4

Recursive Formulae

across time periods

Use Case 4

Recursive Formulae

across time periods

Sales

Volume (0)

Opening

Stock (1) Opening

Stock (0)

Forecast

(0)

Schedules

(0)](https://image.slidesharecdn.com/vembrief-200212180837/75/Virtual-Enterprise-Model-35-2048.jpg)