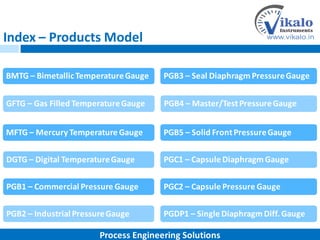

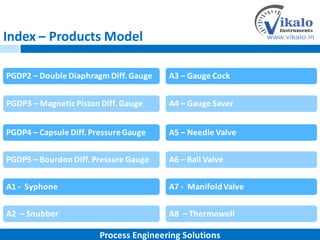

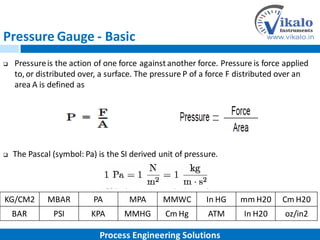

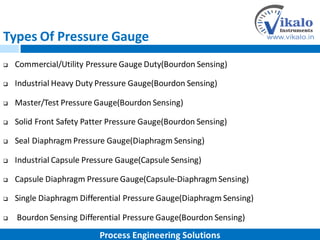

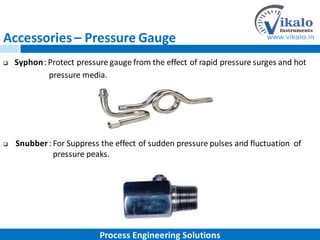

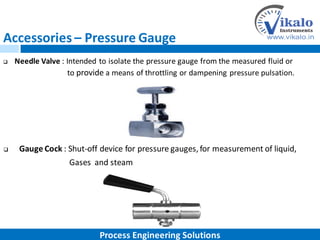

Vikalo Instruments is a manufacturing company specializing in pressure and temperature gauges, aiming to provide innovative process engineering solutions with a focus on upgrading existing products. The company features a team of experienced technocrats and utilizes state-of-the-art technology to meet global standards in various industries, including pharmaceuticals and chemicals. Their product range includes multiple types of thermometers and pressure gauges, all designed to fulfill specific requirements and enhance customer value.