Embed presentation

Downloaded 92 times

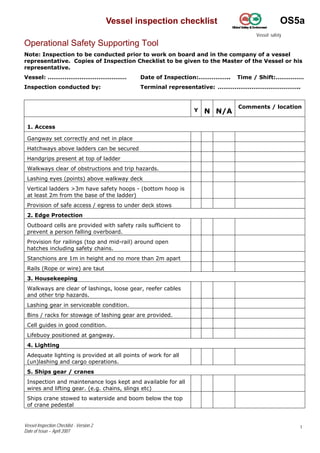

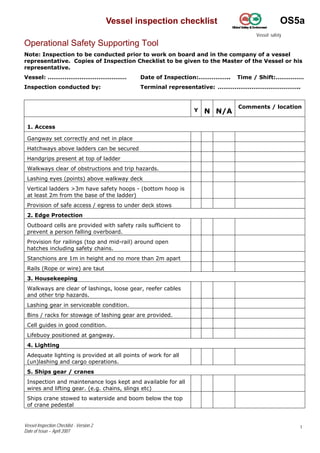

This document is a vessel inspection checklist used to ensure vessel safety. It lists items to check such as proper access to the vessel via gangways and ladders, adequate edge protection around open areas, good housekeeping with walkways clear of hazards, sufficient lighting for cargo operations, and maintenance of lifting gear and cranes. Inspectors use this checklist to verify the vessel is safe prior to any work and provide a copy to the vessel's master noting any issues.