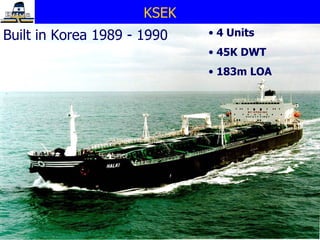

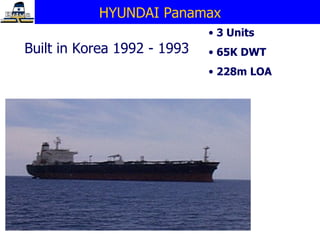

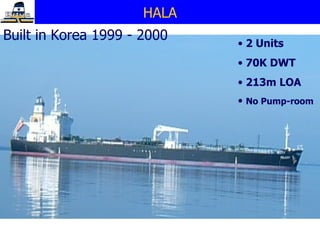

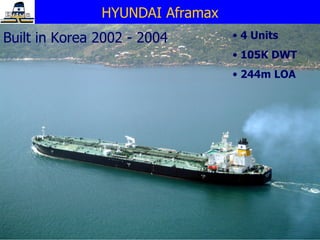

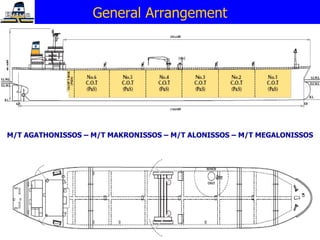

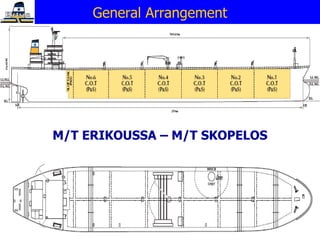

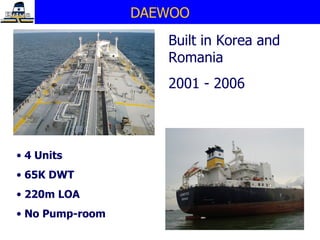

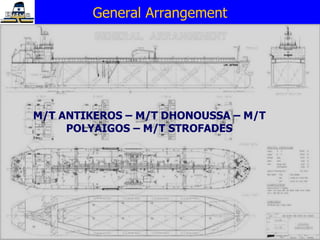

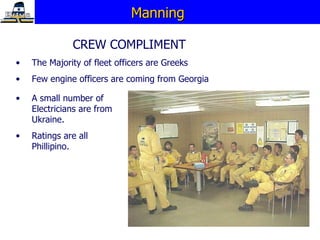

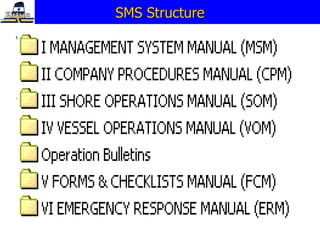

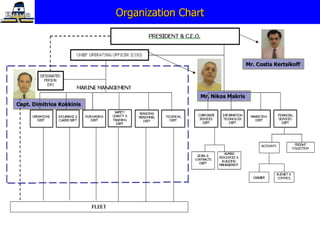

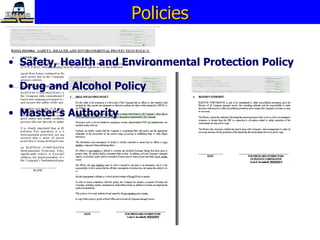

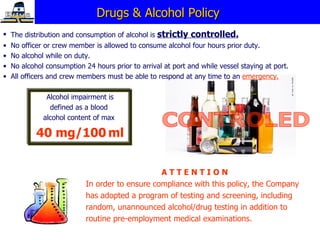

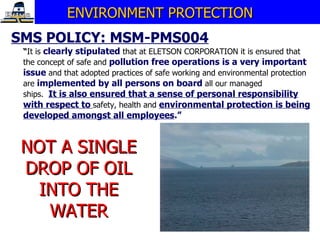

Eletson Corporation provides a familiarization and induction course for new employees that covers the company's profile, safety management system, and maritime security. The document outlines Eletson's history since 1966, describes its current fleet of 40 double hull oil tankers, and details the company's safety policies and procedures, including its safety management system, drug and alcohol policy, and job descriptions and expectations for crew members.