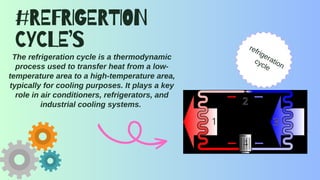

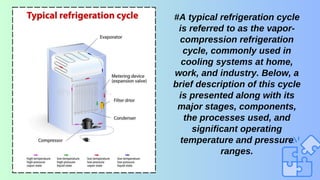

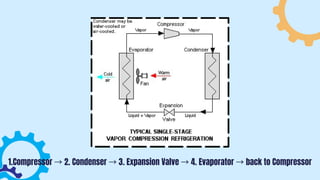

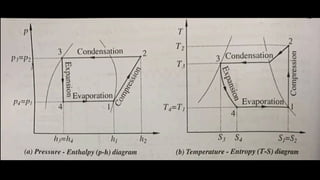

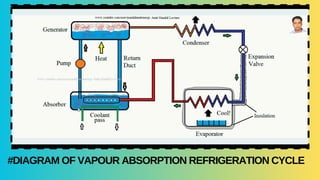

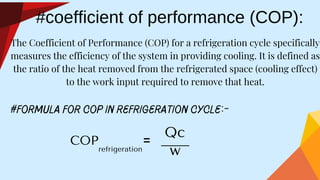

The document discusses thermodynamic systems in everyday appliances, particularly refrigerators, which transfer heat from low to high temperatures for food preservation. It details two main types of refrigerators: natural and mechanical, and explains the vapor-compression refrigeration cycle's components and operations. The text also highlights improvements in efficiency through variable-speed compressors and the importance of performance and environmental considerations in refrigeration technology.