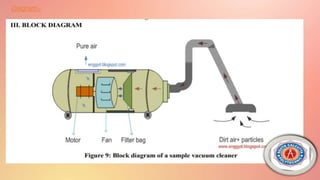

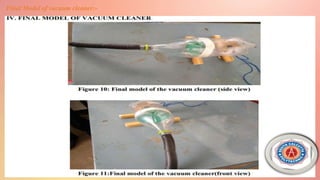

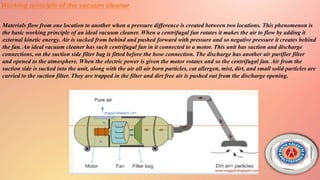

This document presents the final year project of 12 students on designing and implementing a low-cost vacuum cleaner. The project involved building a vacuum cleaner using common household materials like plastic bottles, a 12V DC motor, and a deodorant can. The summary describes the 5 main steps followed to build the vacuum cleaner, including cutting bottles to form the structure, making a fan from a deodorant can, attaching the motor and fan, adding a nozzle and suction tube, and wiring it to a power source. In conclusion, the document discusses the working principle of vacuum cleaners and potential areas of improvement for the designed prototype.