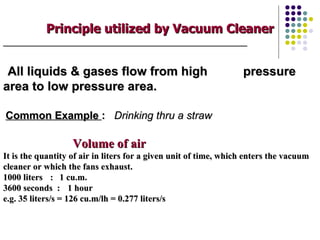

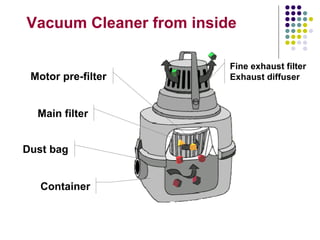

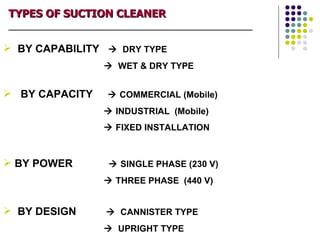

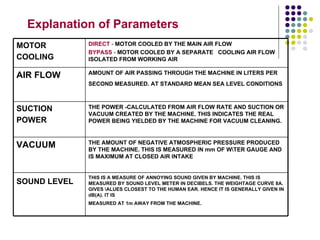

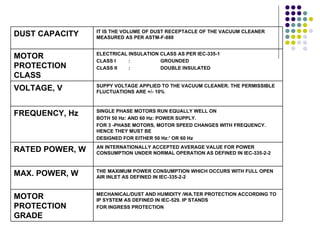

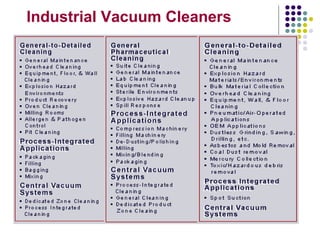

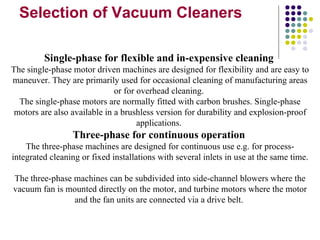

This document provides information on suction cleaners, also known as vacuum cleaners. It discusses the principles of vacuum and how suction cleaners utilize differences in air pressure. It also outlines different types of suction cleaners categorized by capability, capacity, power source, and design. Key features of suction cleaners like motors, filters, bodies, and accessories are explained. The document also discusses parameters like air flow, suction power, vacuum, sound level, and dust capacity.