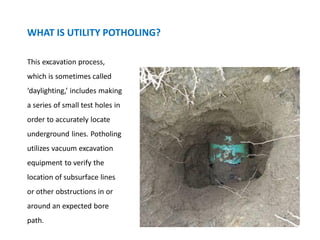

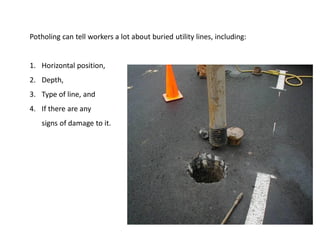

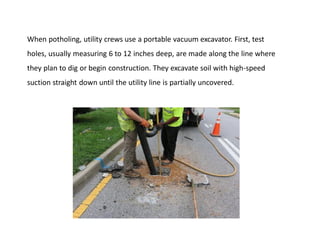

Utility potholing services in Virginia Beach enhance safety by accurately locating underground utility lines through a process known as daylighting, which uses vacuum excavation to create small test holes. This method is beneficial for preventing damage to water, electrical, gas, telecommunications, and fiber optic lines during excavation projects. Advanced Infrastructure Mapping, LLC offers these services with well-trained staff and state-of-the-art equipment, ensuring timely and professional execution while minimizing risks and project delays.