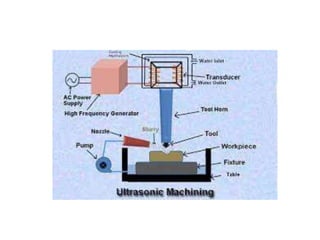

Ultrasonic machining (USM) is a precision machining process that uses high-frequency mechanical vibrations to remove material from hard and brittle materials. It employs an ultrasonic transducer, abrasive slurry, and controlled force to achieve intricate shapes and high surface finishes, making it suitable for industries such as aerospace, medical, and semiconductor. Applications include manufacturing turbine blades, dental implants, and precision molds.