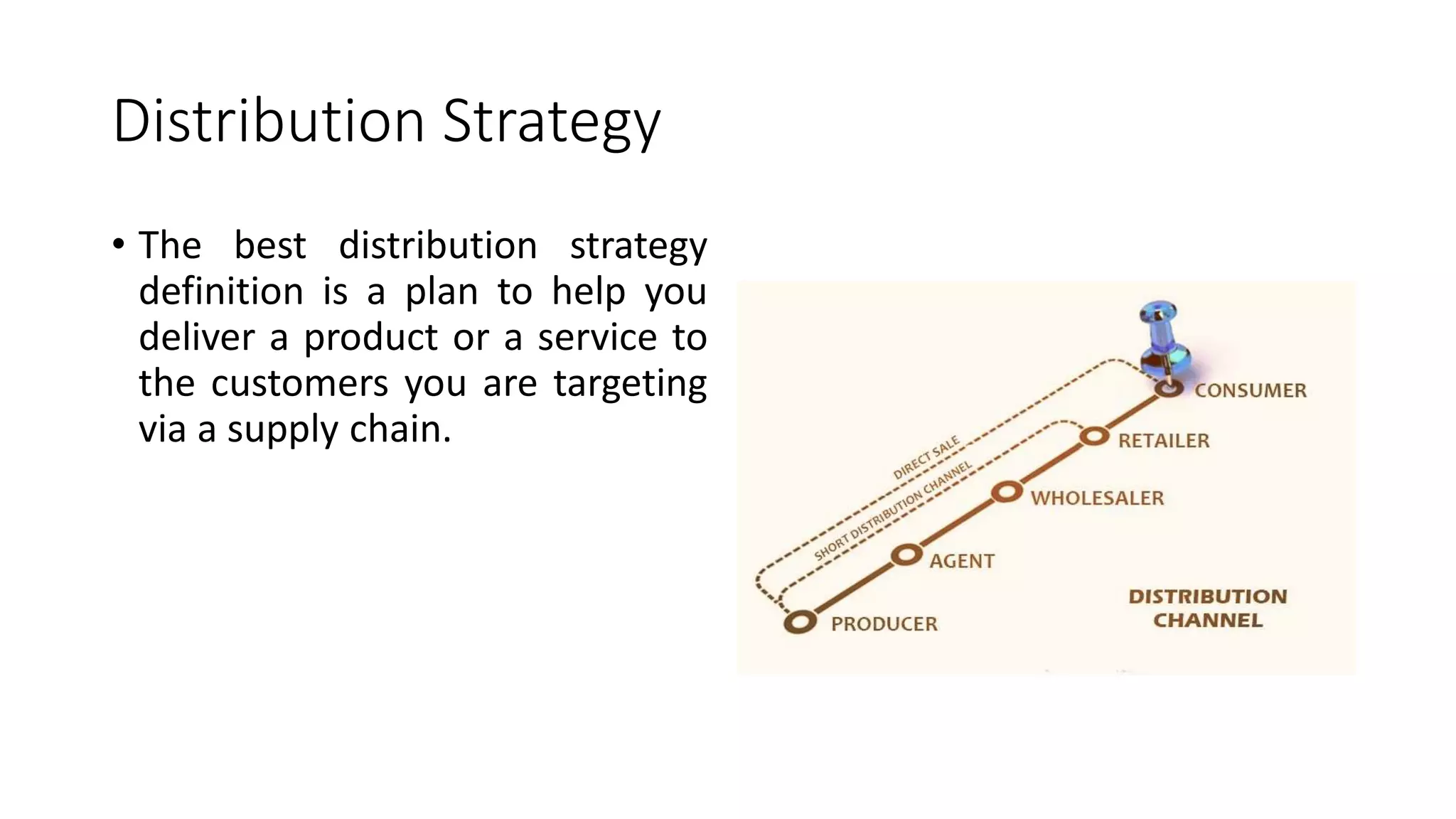

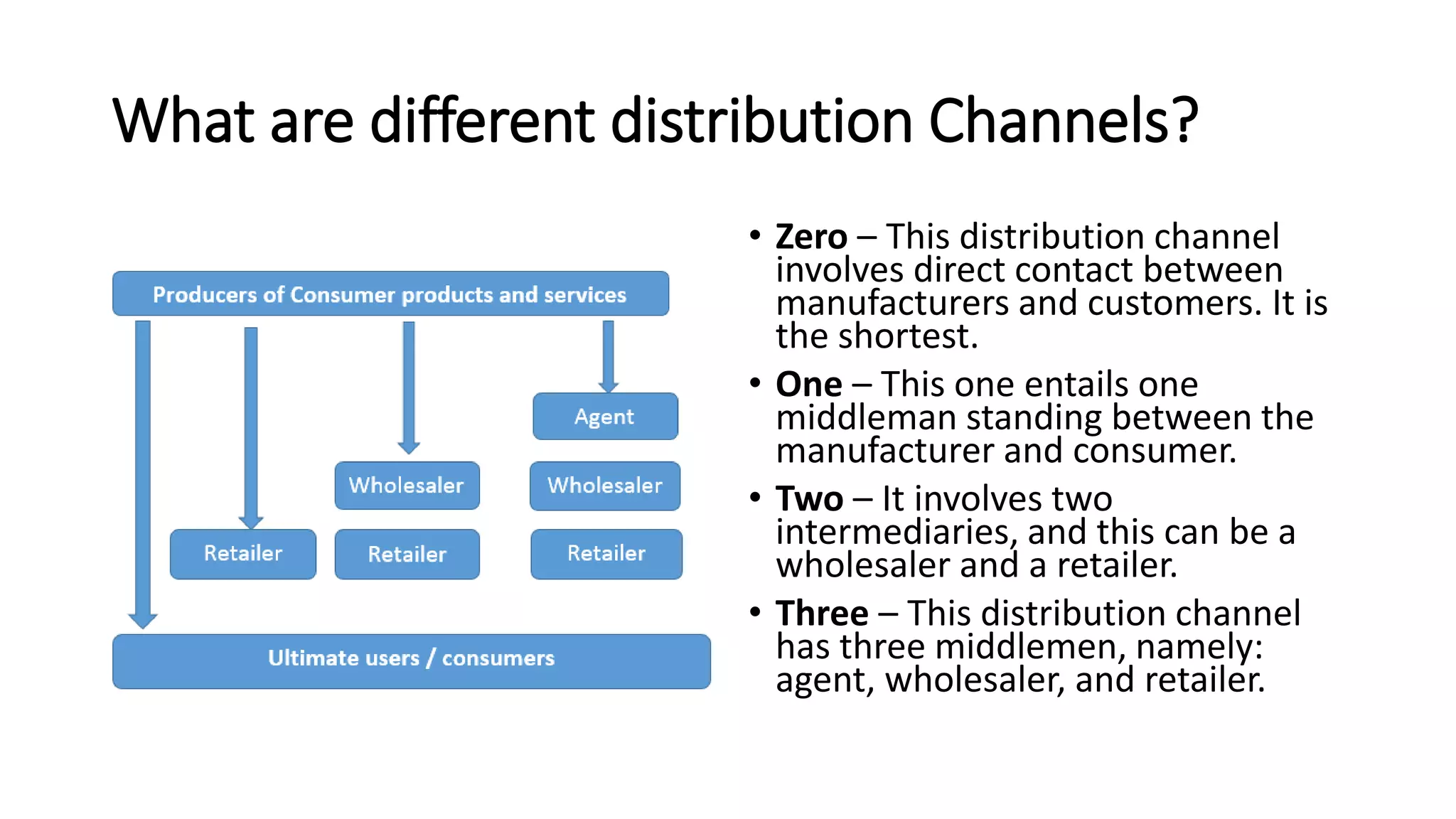

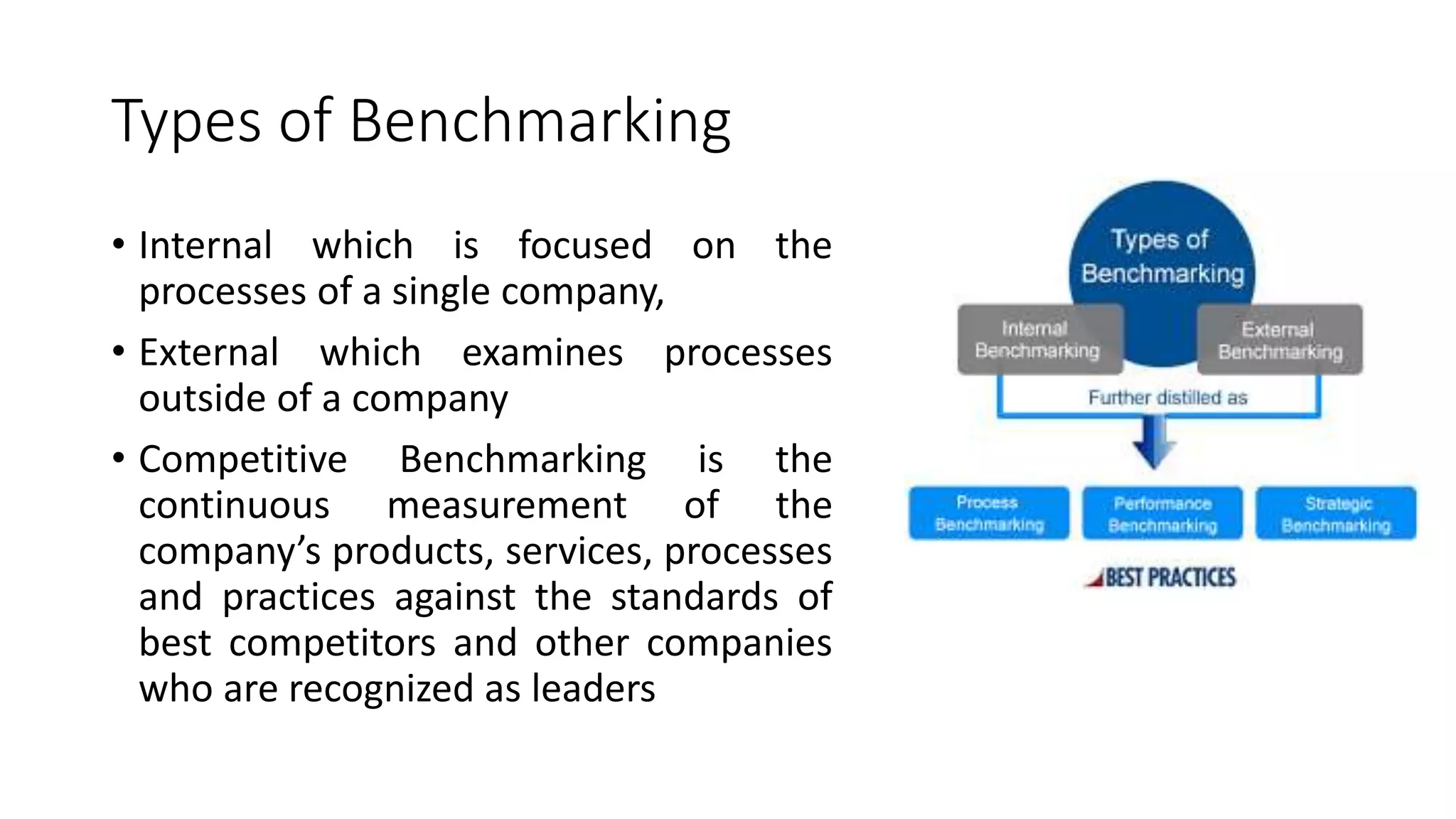

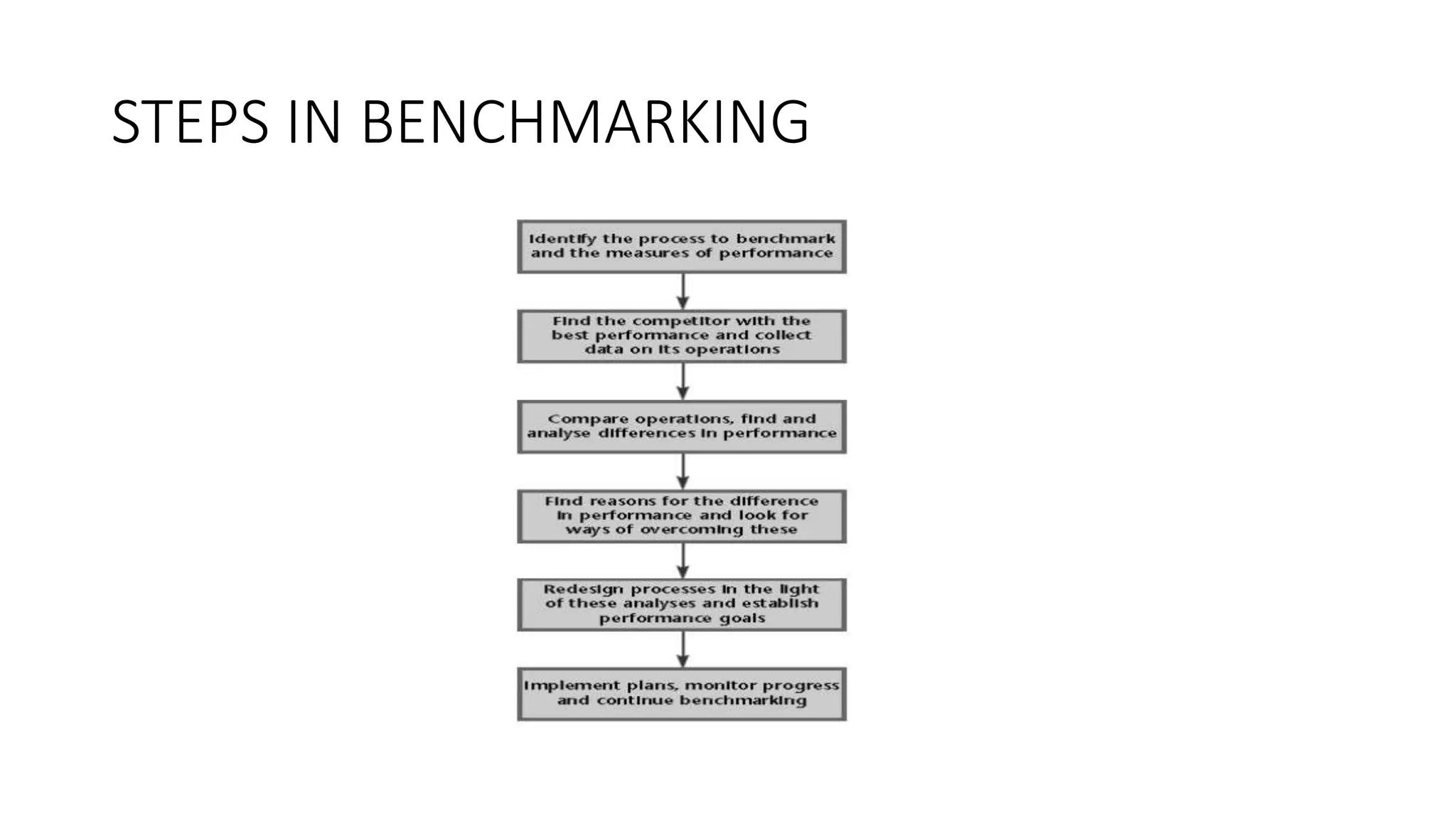

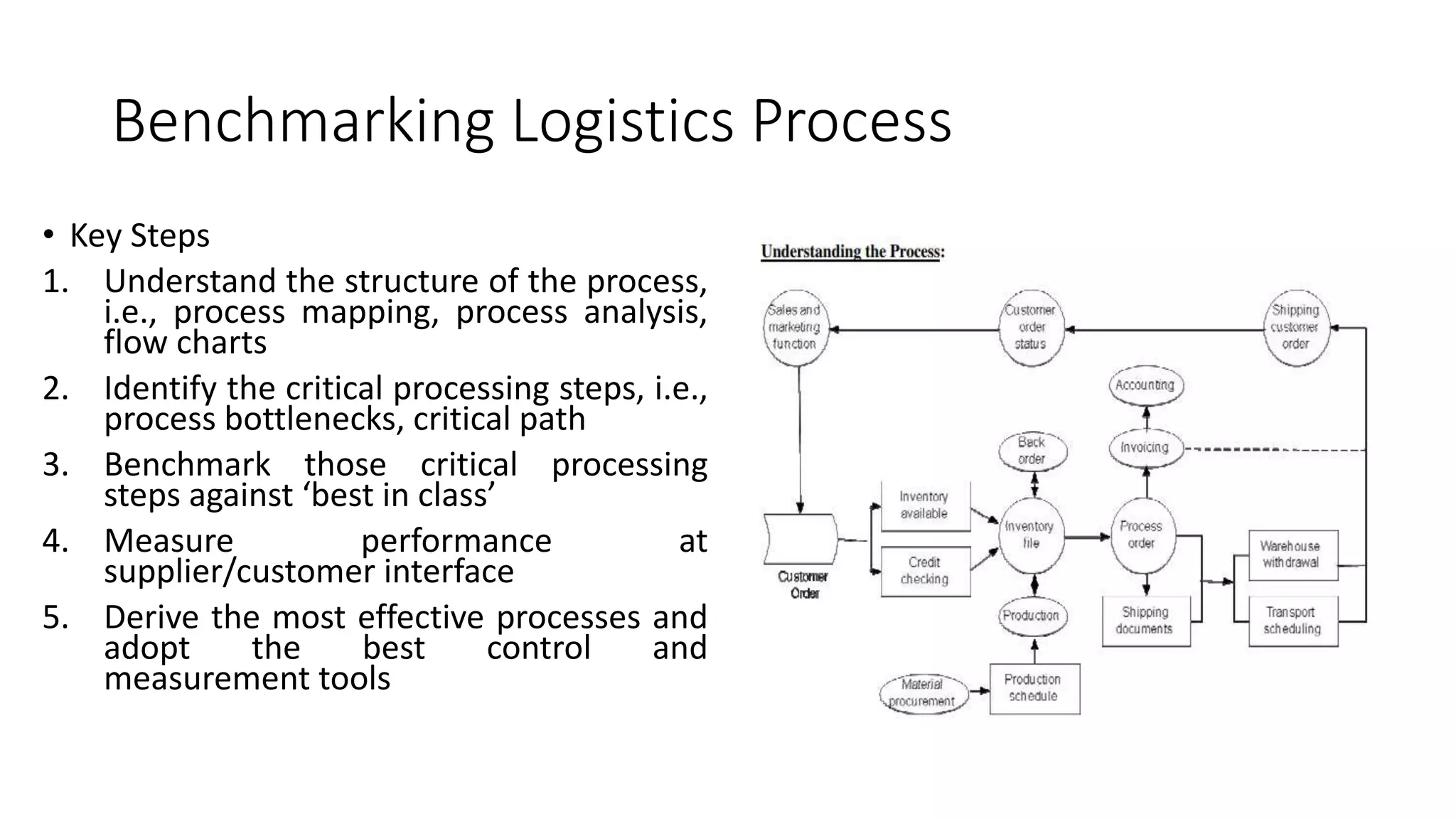

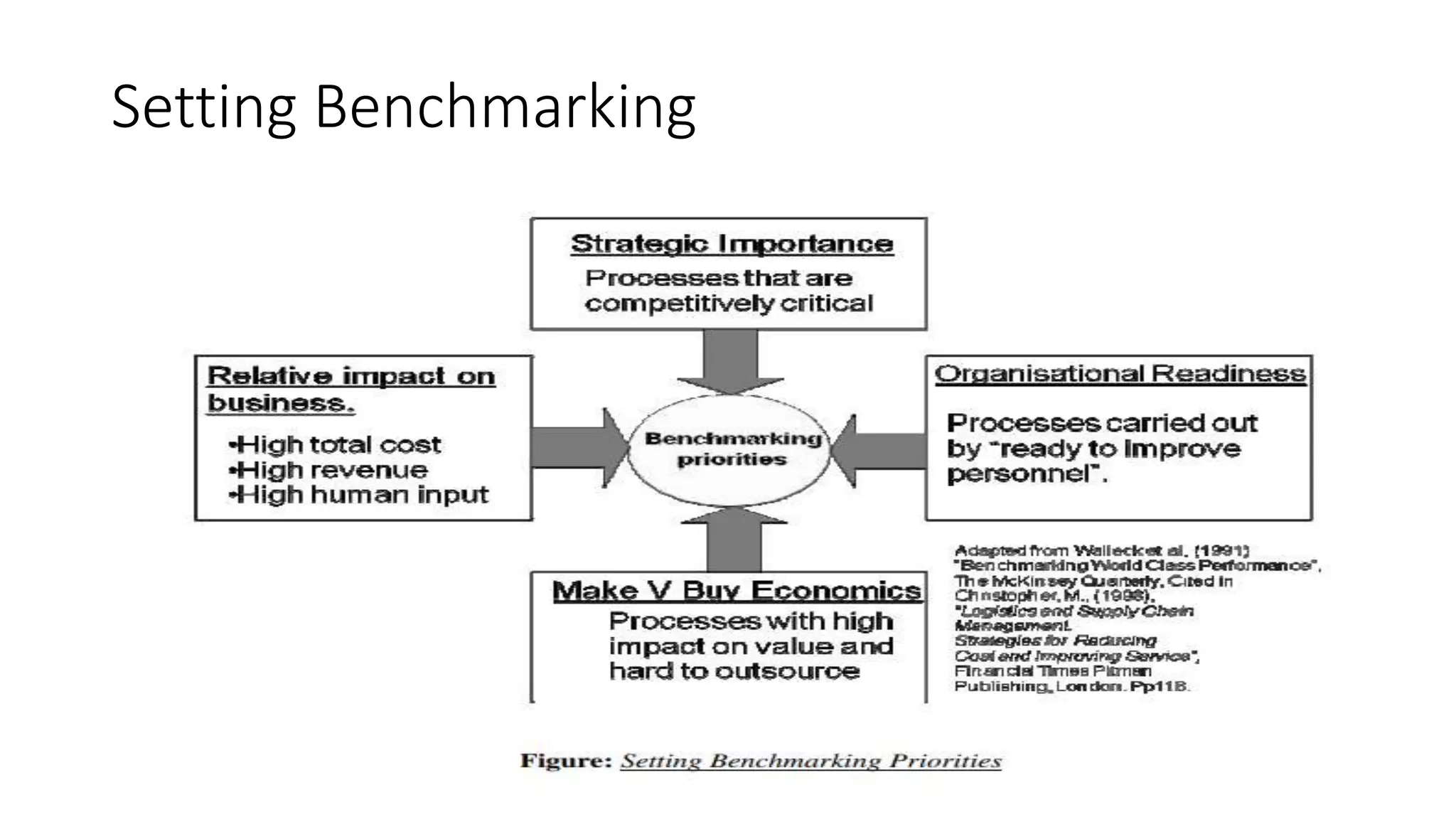

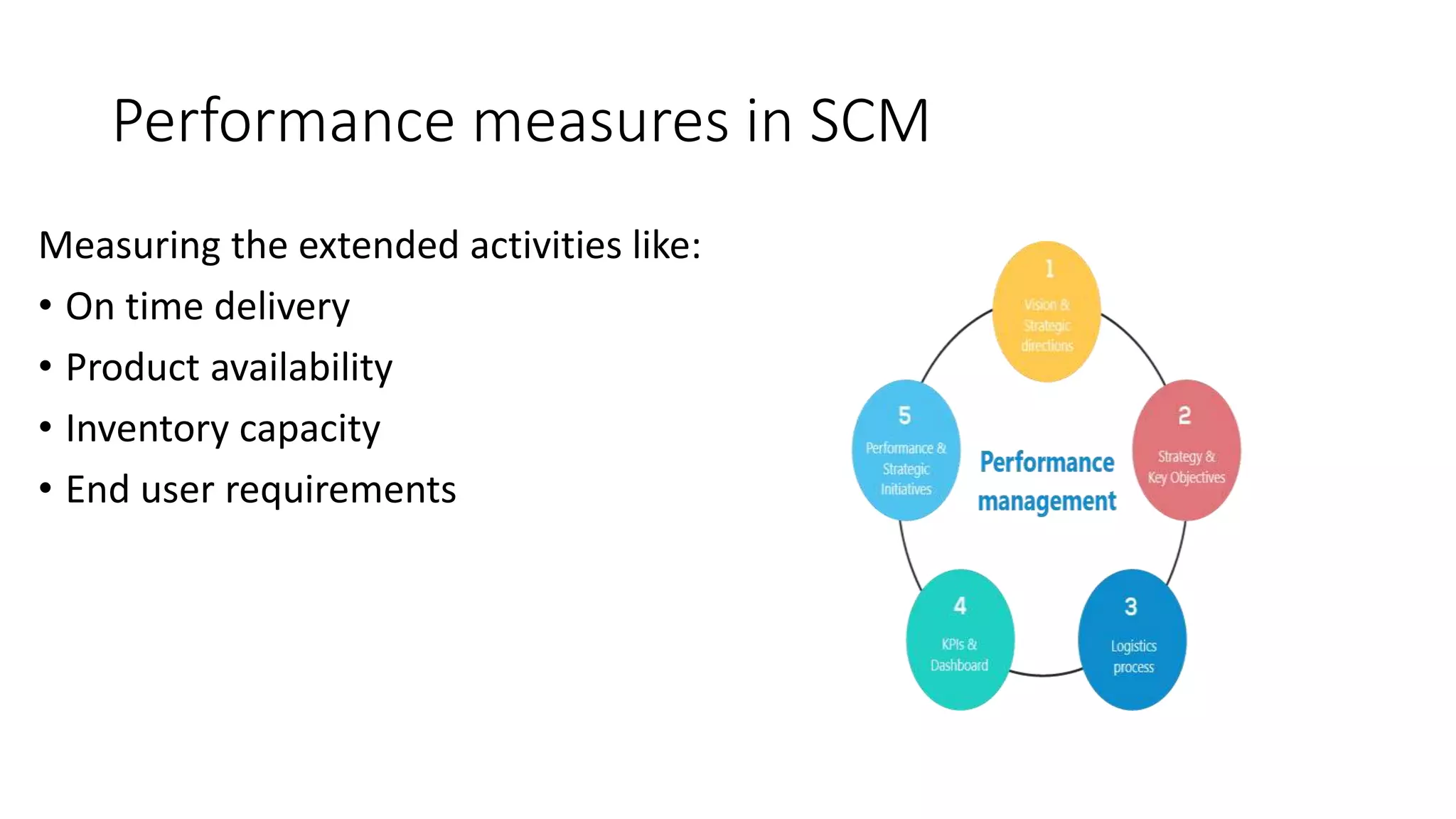

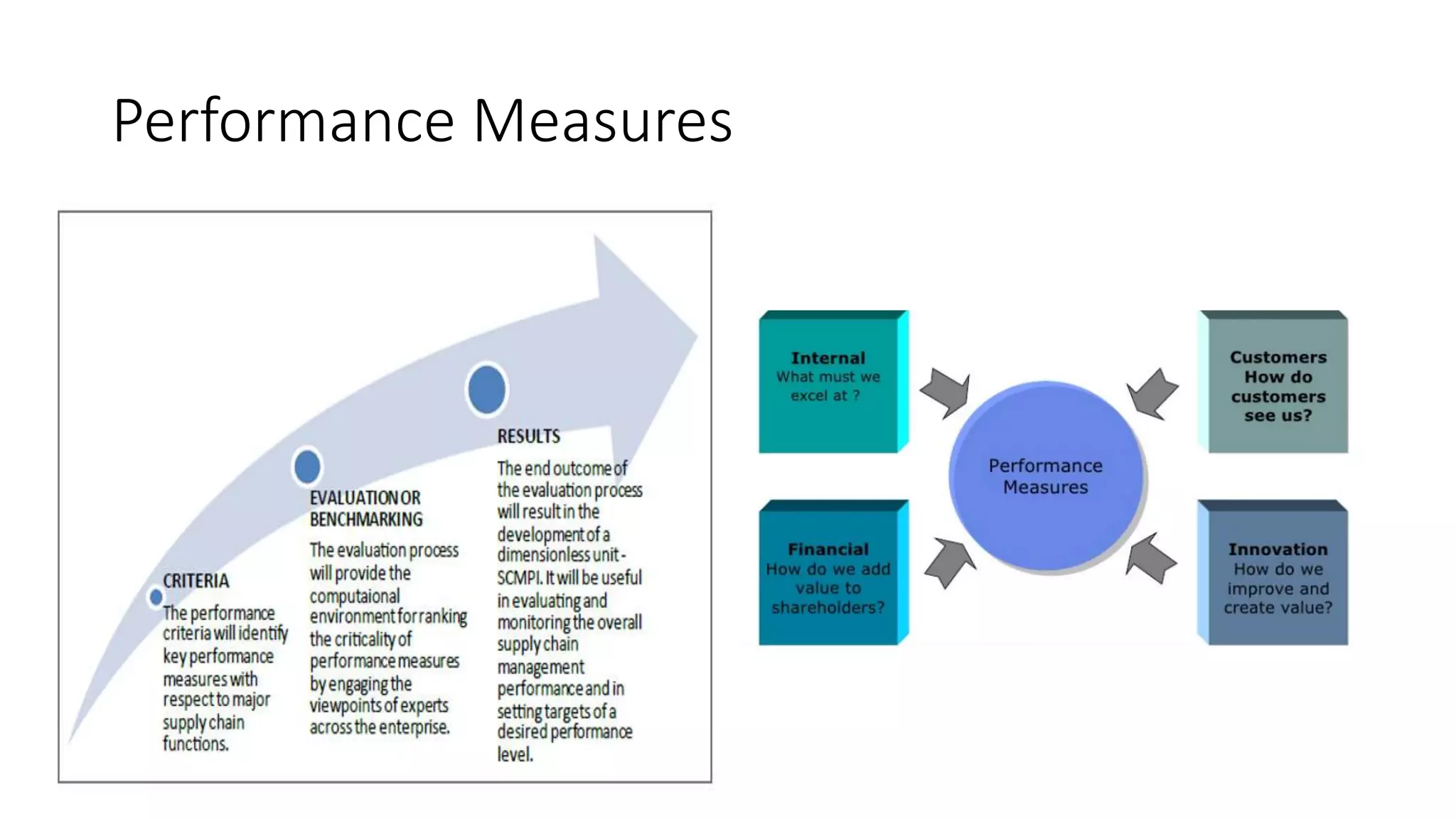

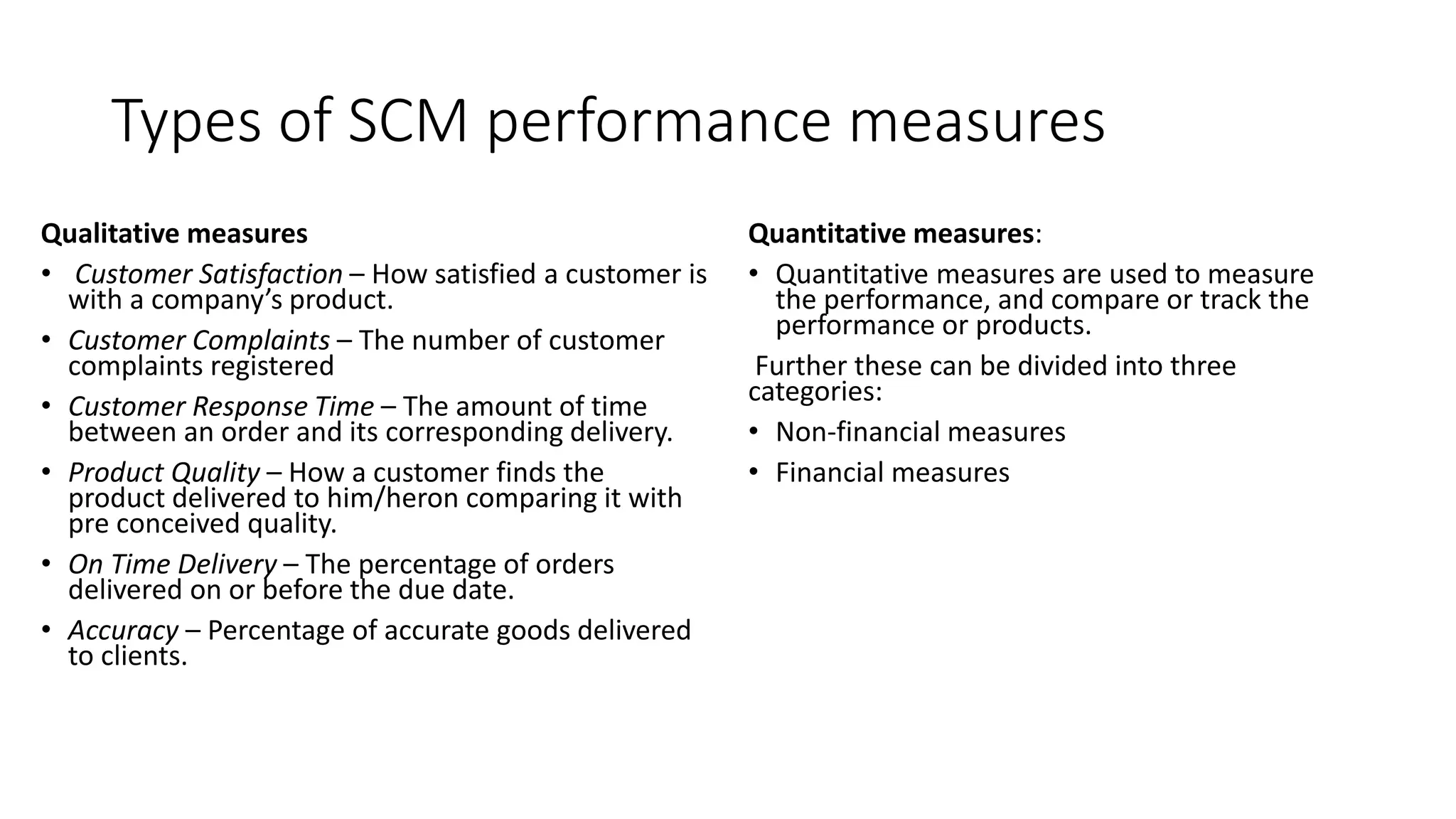

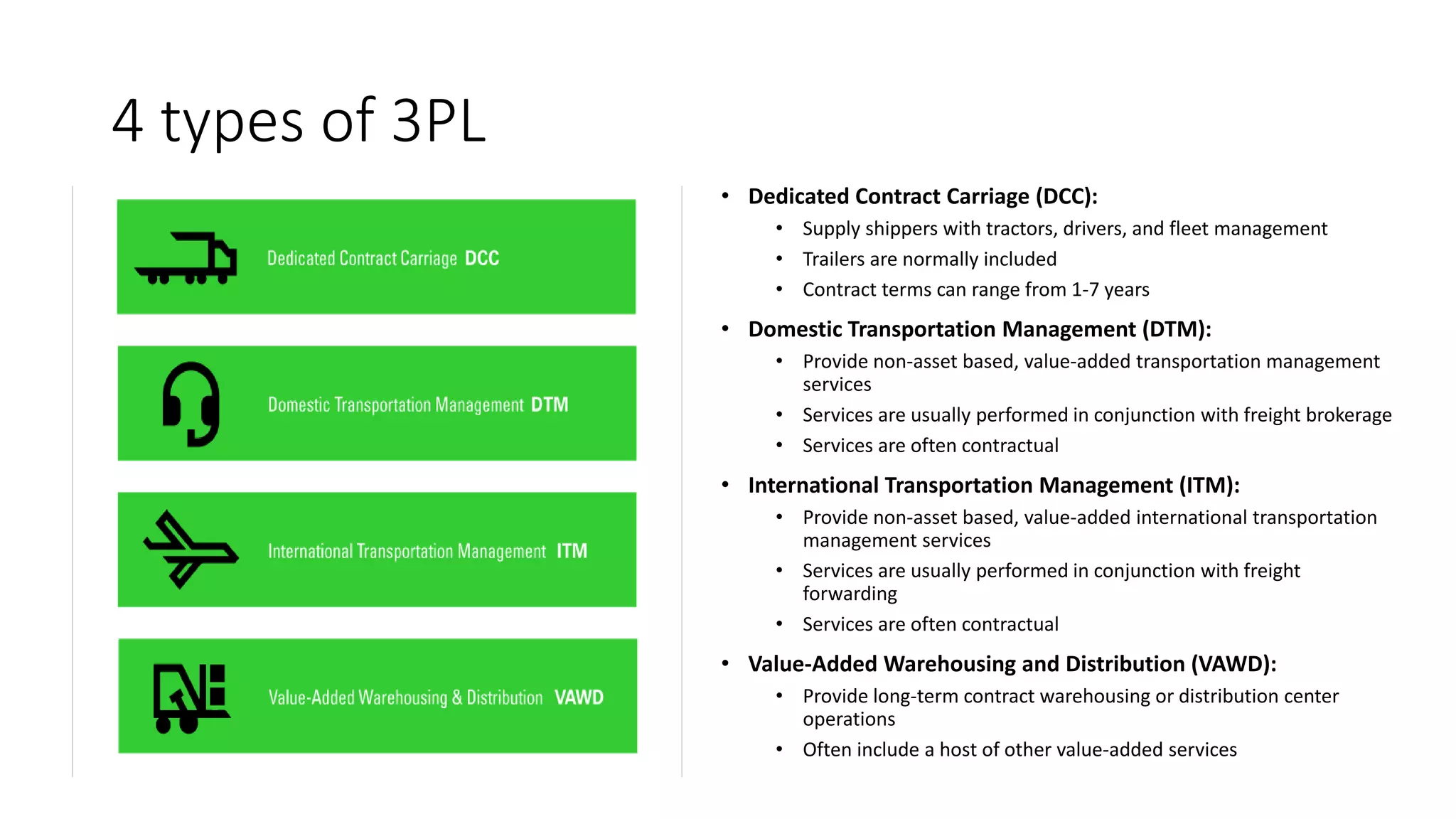

The document discusses distribution strategies and logistics supply chain management. It defines distribution strategy as a plan to deliver products or services to targeted customers via a supply chain. It describes different types of distribution strategies like direct, indirect, intensive, exclusive, and selective channels. It also discusses distribution channels from zero intermediaries to three intermediaries. The document then covers benchmarking, describing it as measuring performance against best practices to improve. It outlines steps in benchmarking, components like financial and product benchmarking, and benchmarking the supply chain. Finally, it discusses outsourcing logistics, types of third-party logistics providers, and costs in logistics supply chain management.