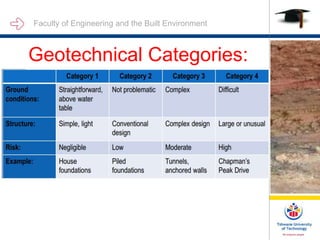

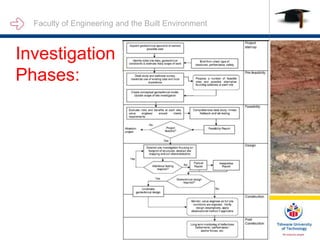

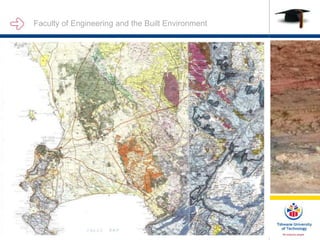

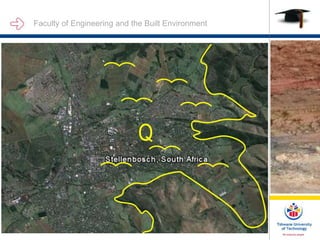

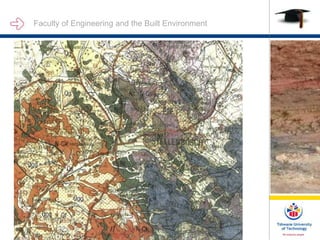

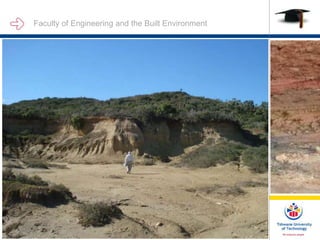

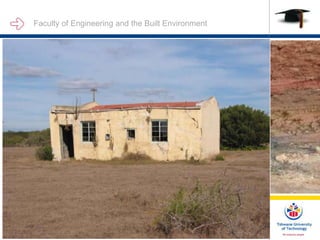

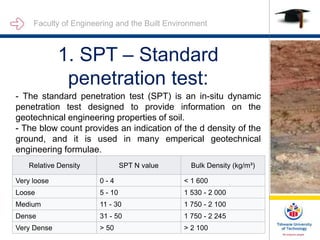

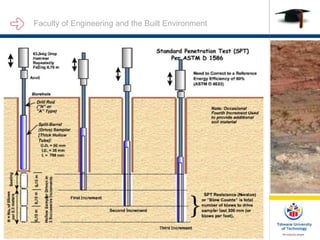

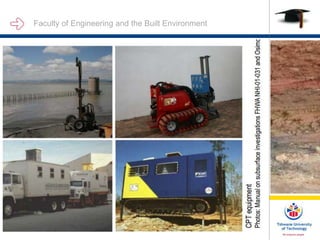

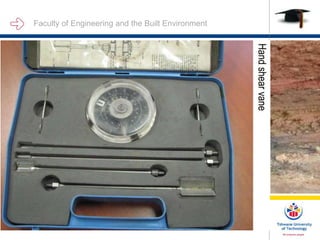

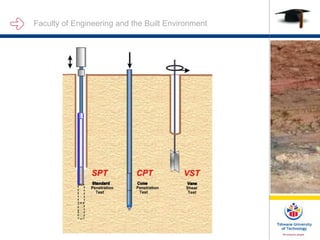

This document discusses site investigation methods for geotechnical engineering projects. It describes desk studies, site walkovers, and various in situ and laboratory tests to characterize soil properties, including standard penetration tests, dynamic probing, cone penetration tests, vane shear tests, and plate load tests. The tests are used to evaluate properties like density, shear strength, and bearing capacity to inform foundation design.