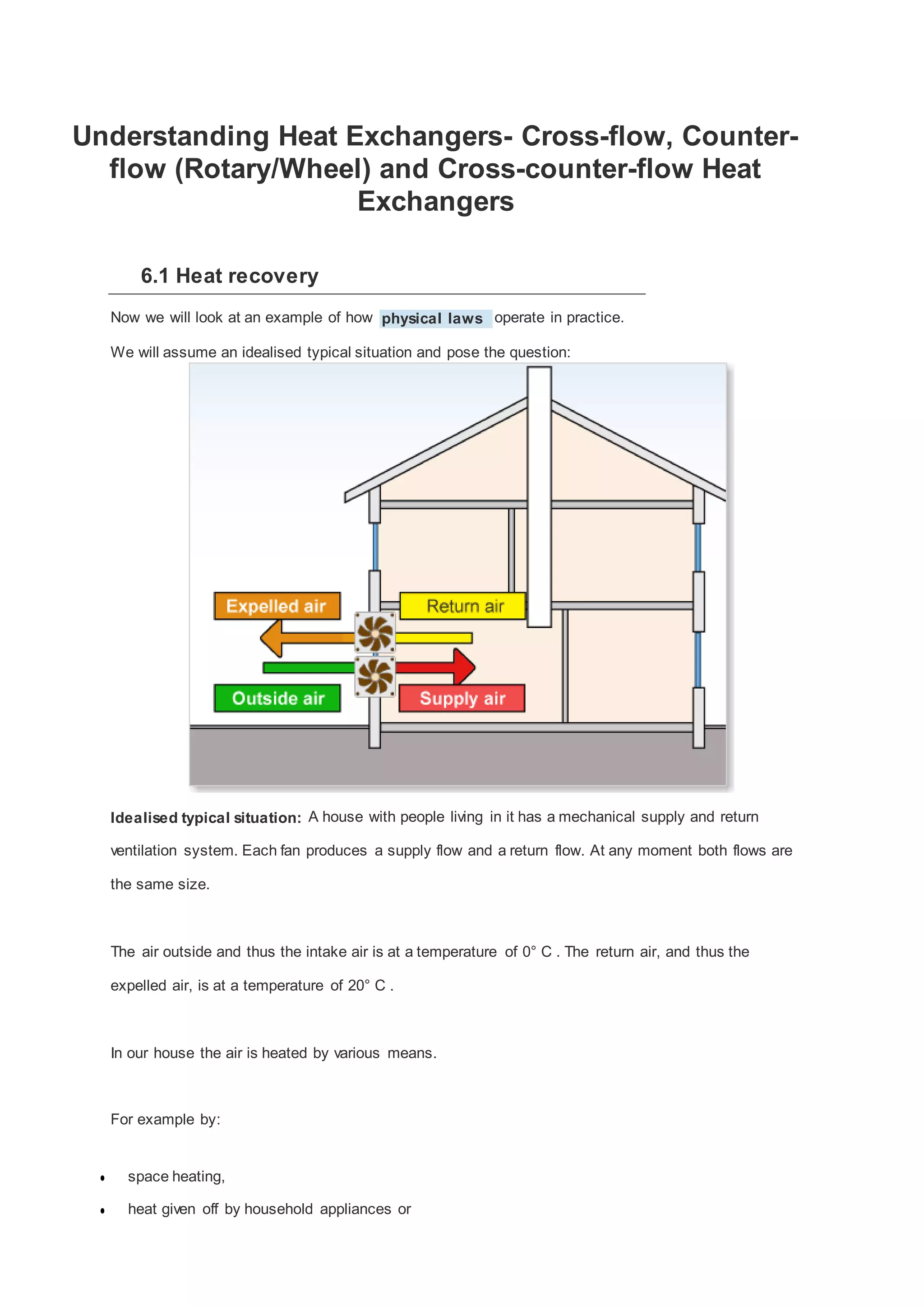

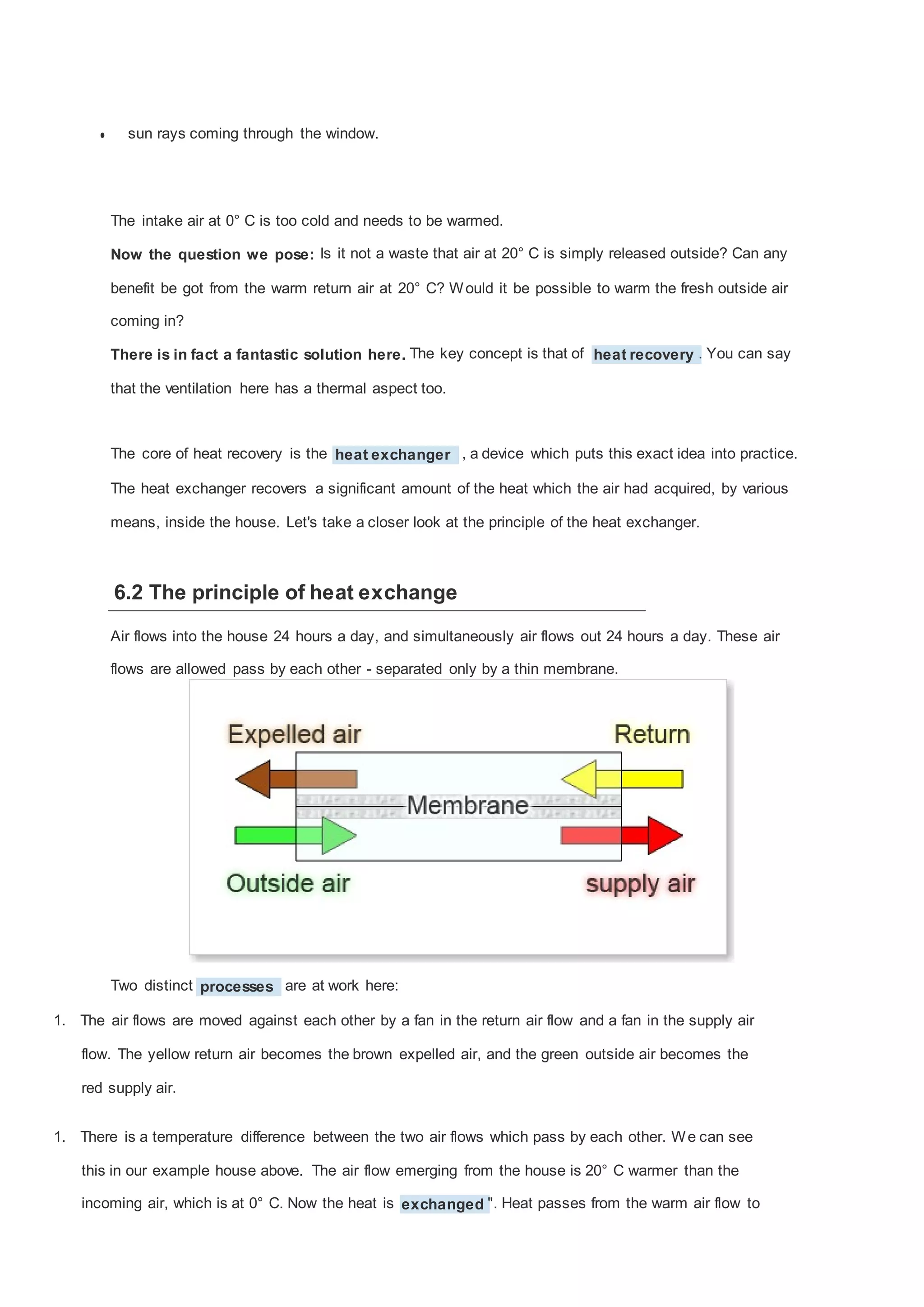

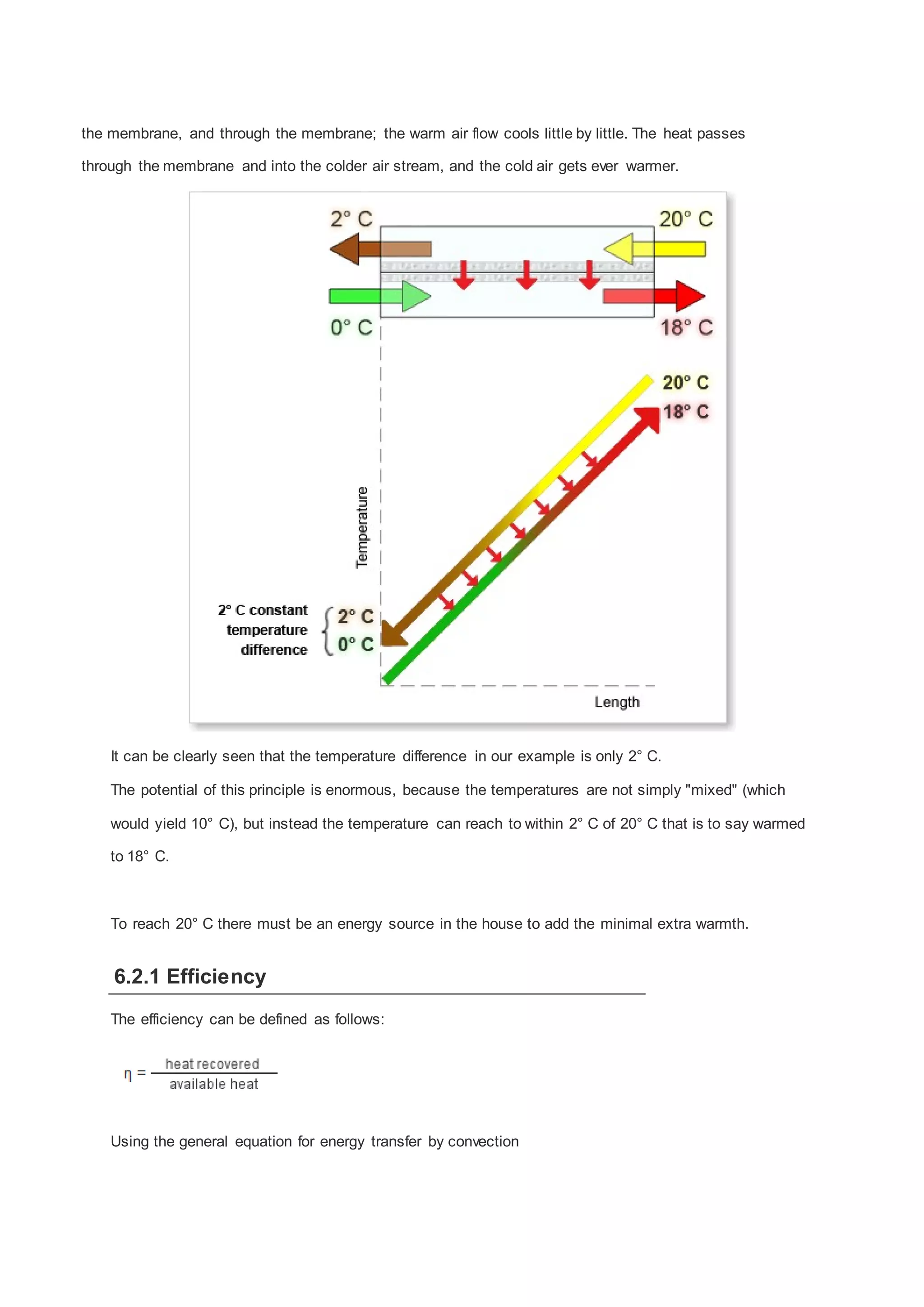

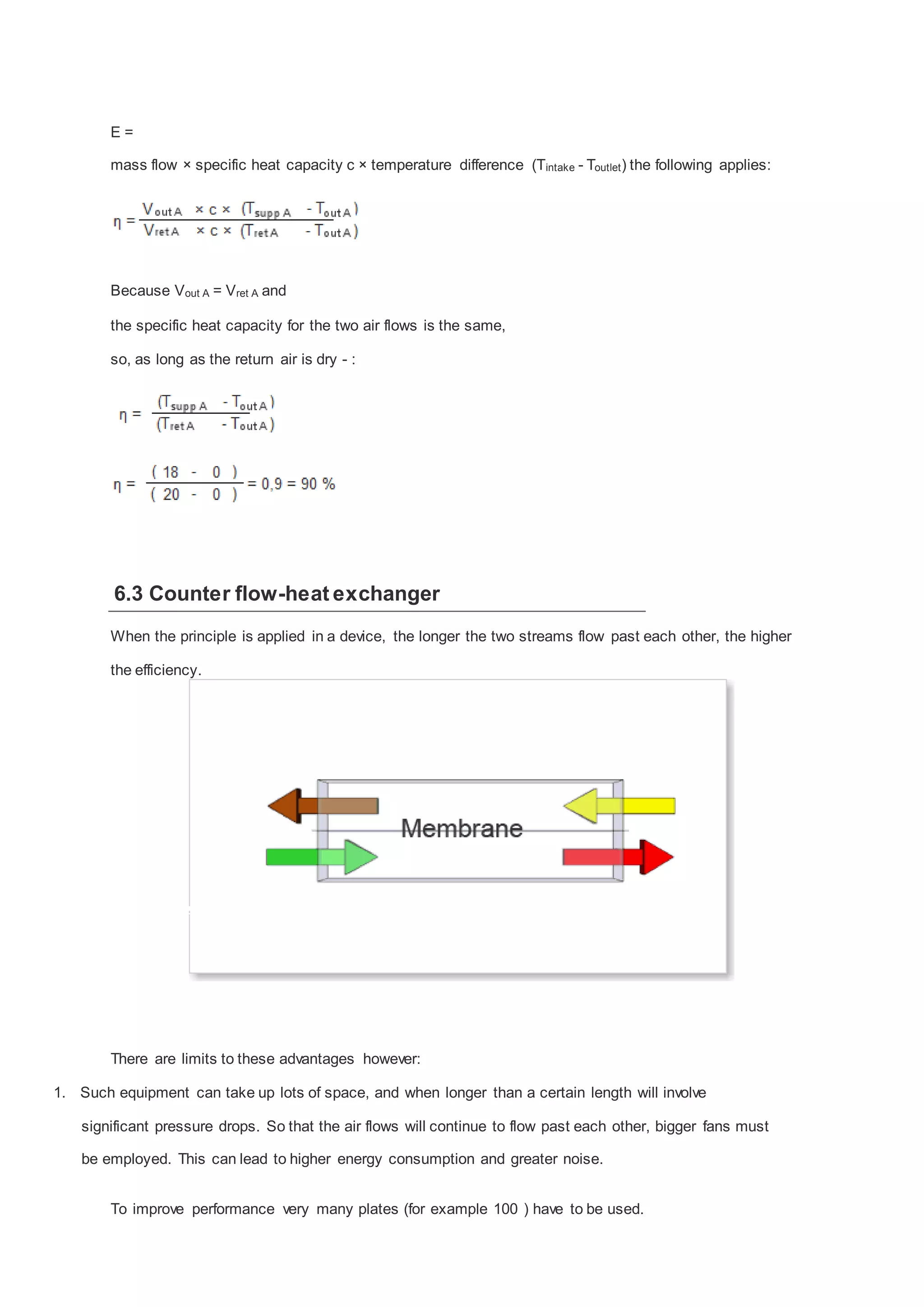

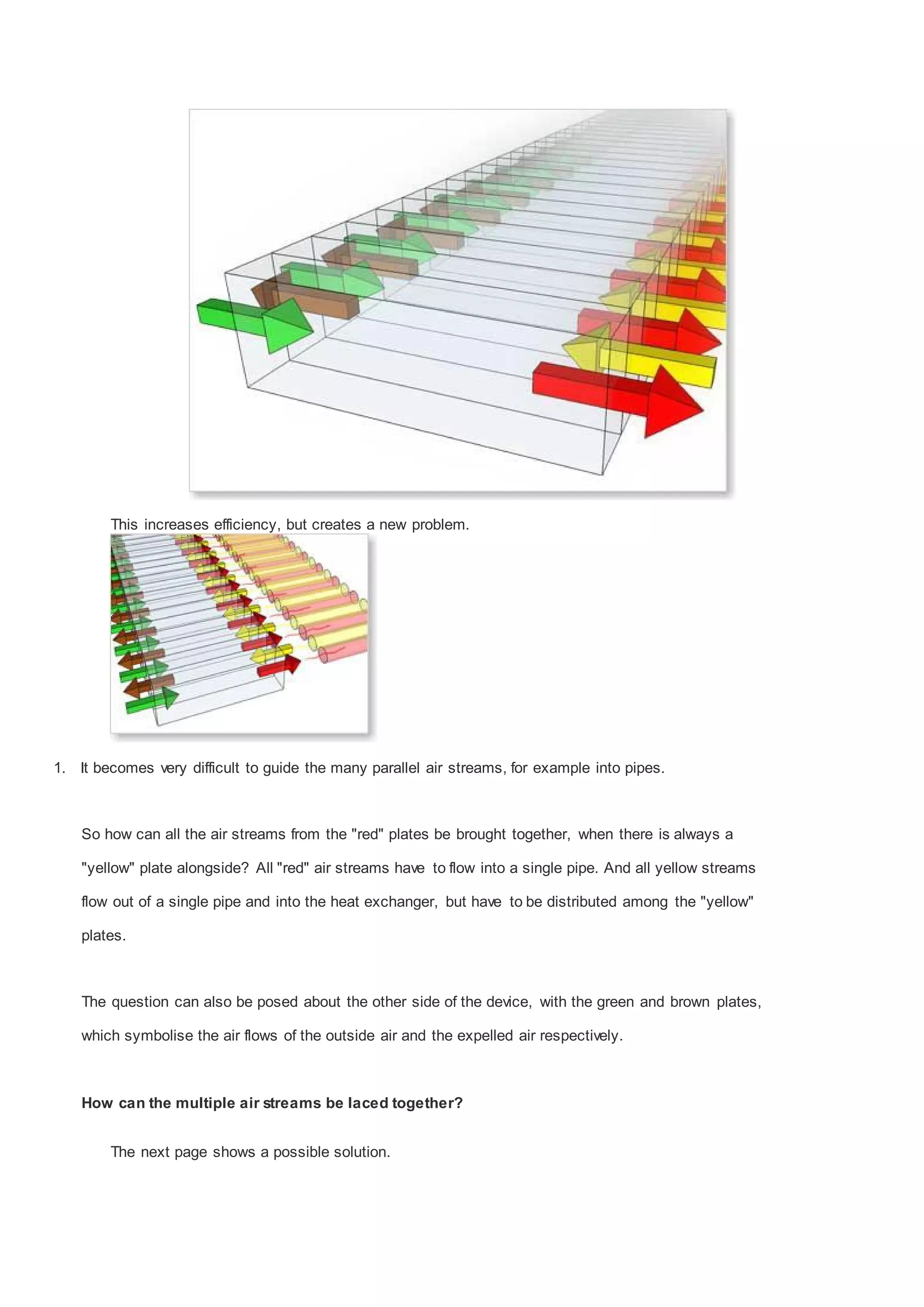

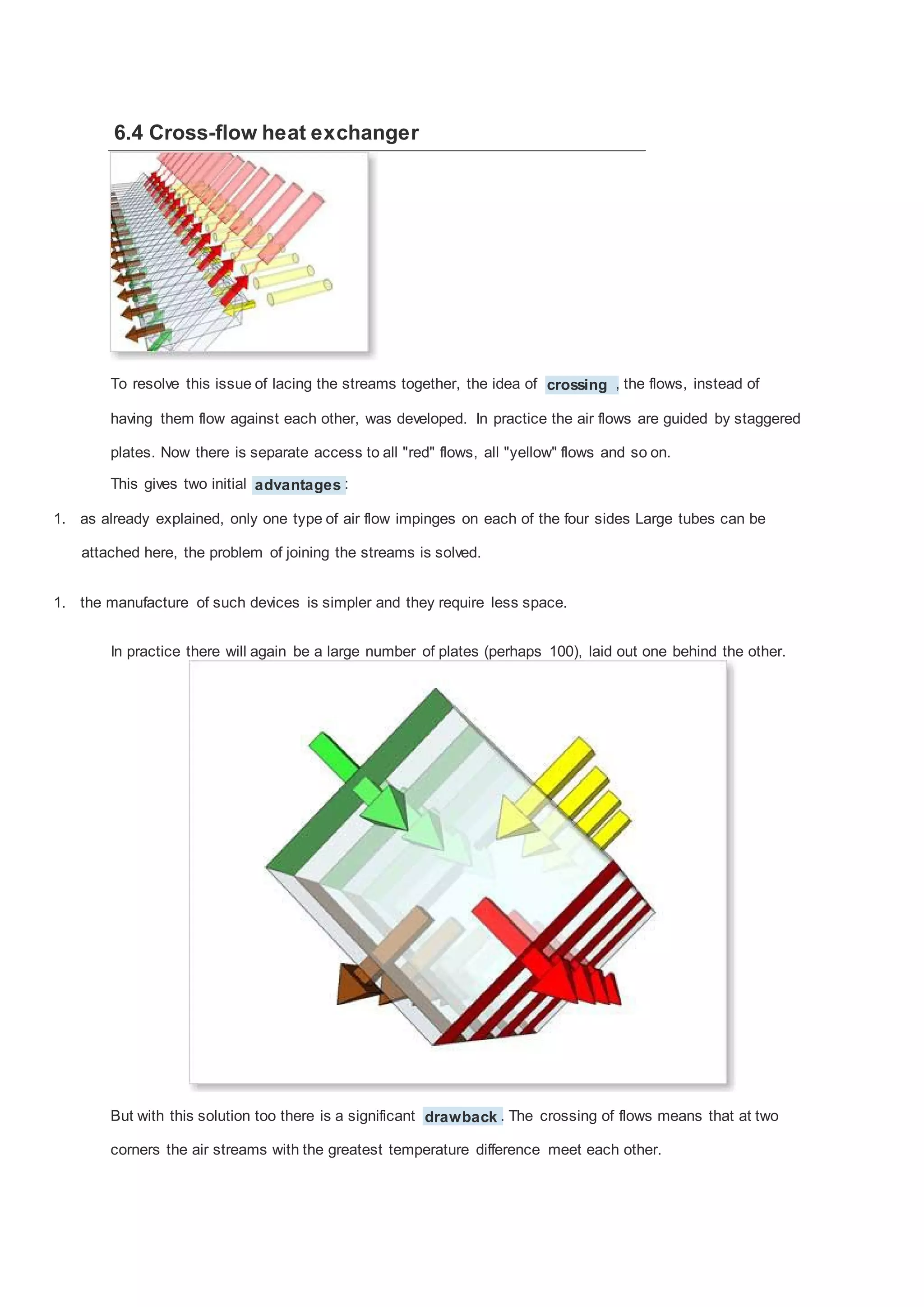

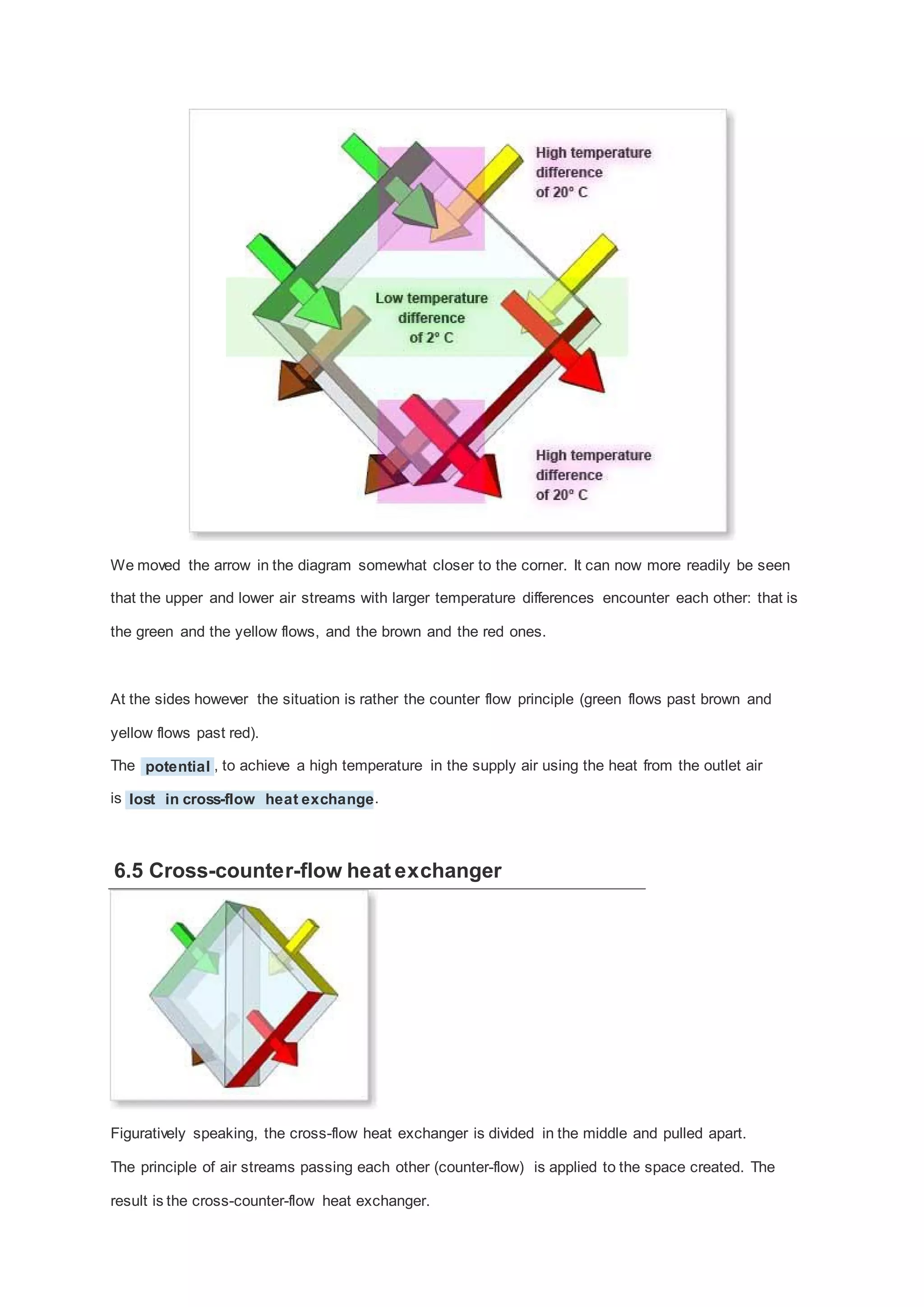

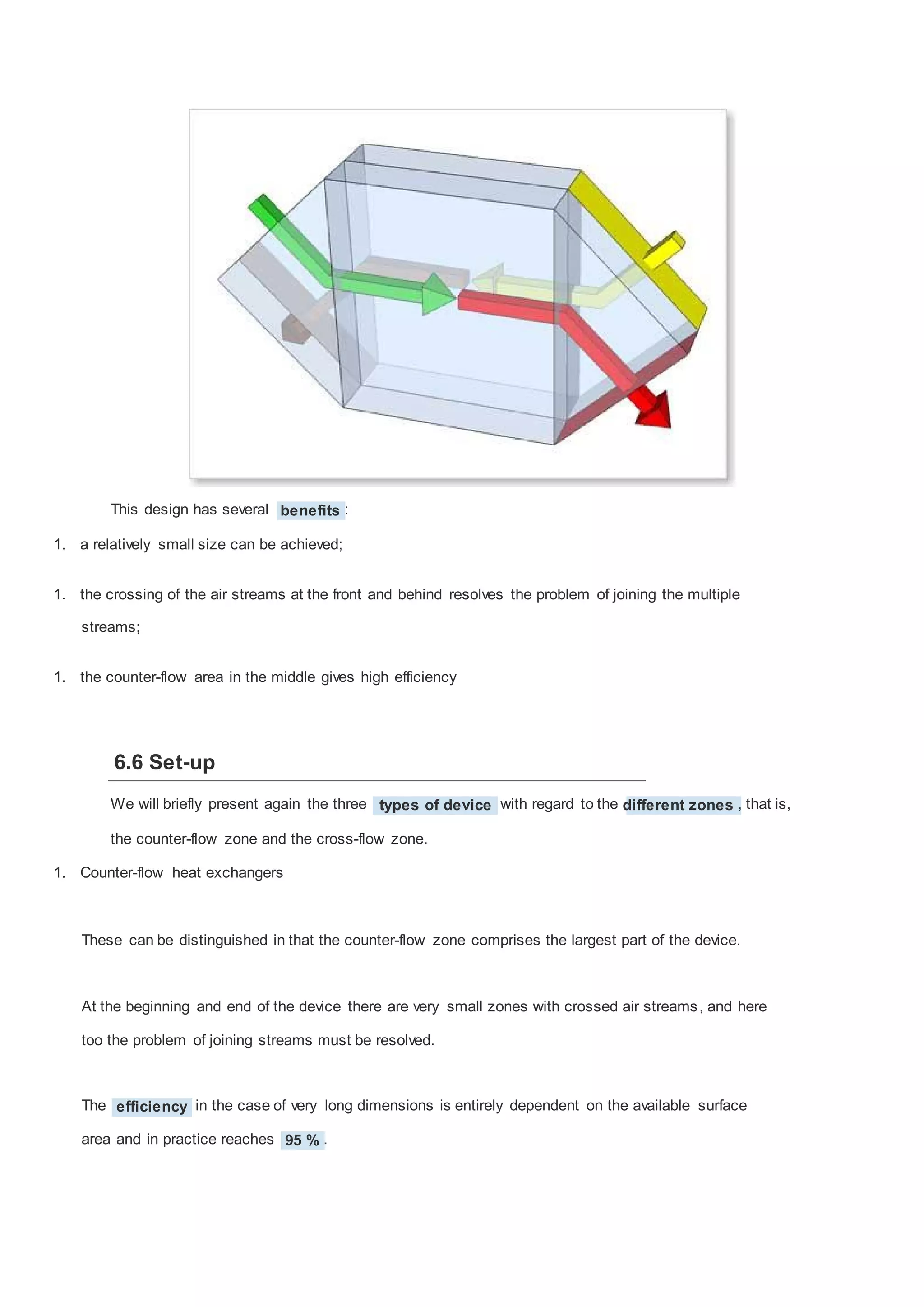

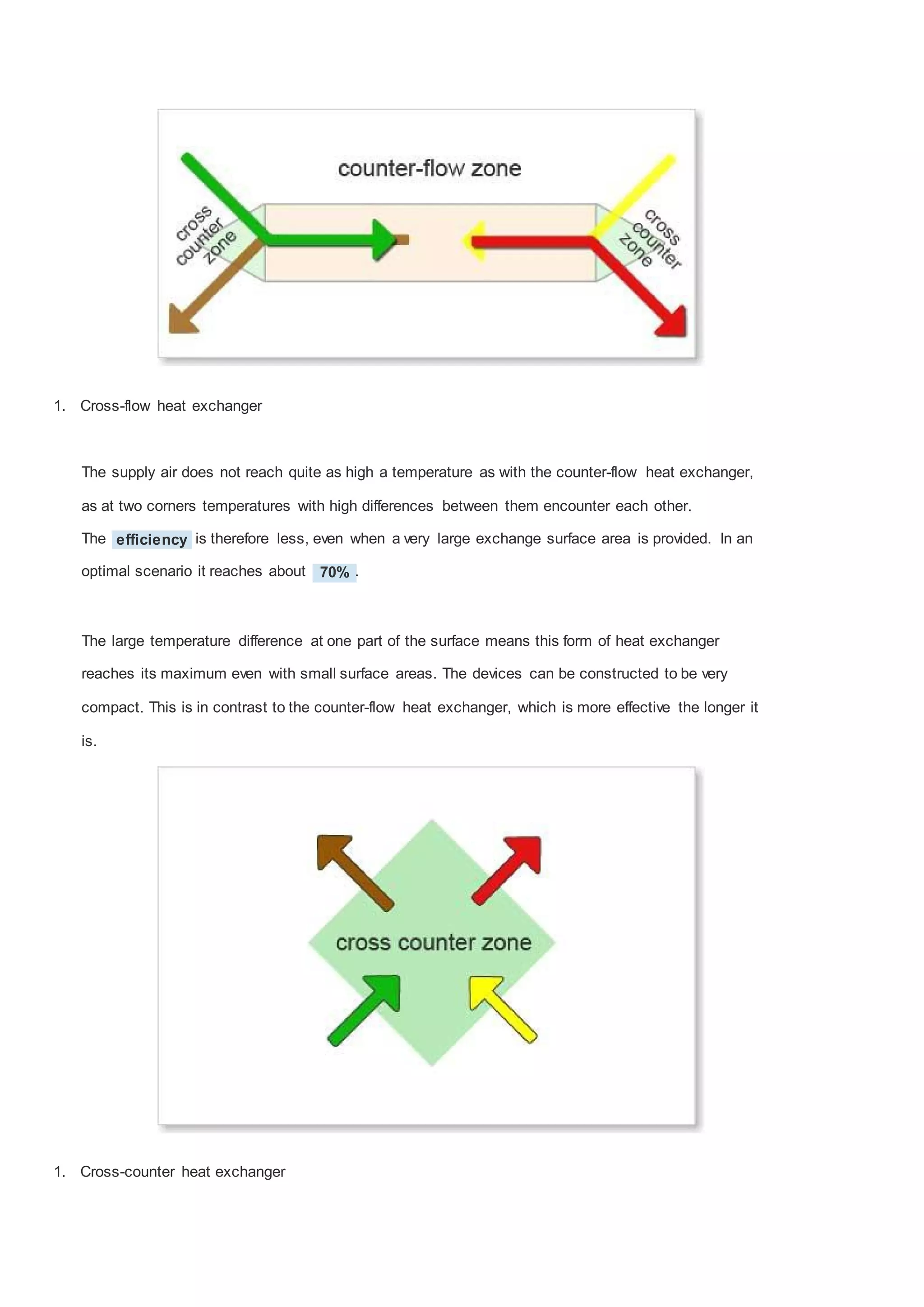

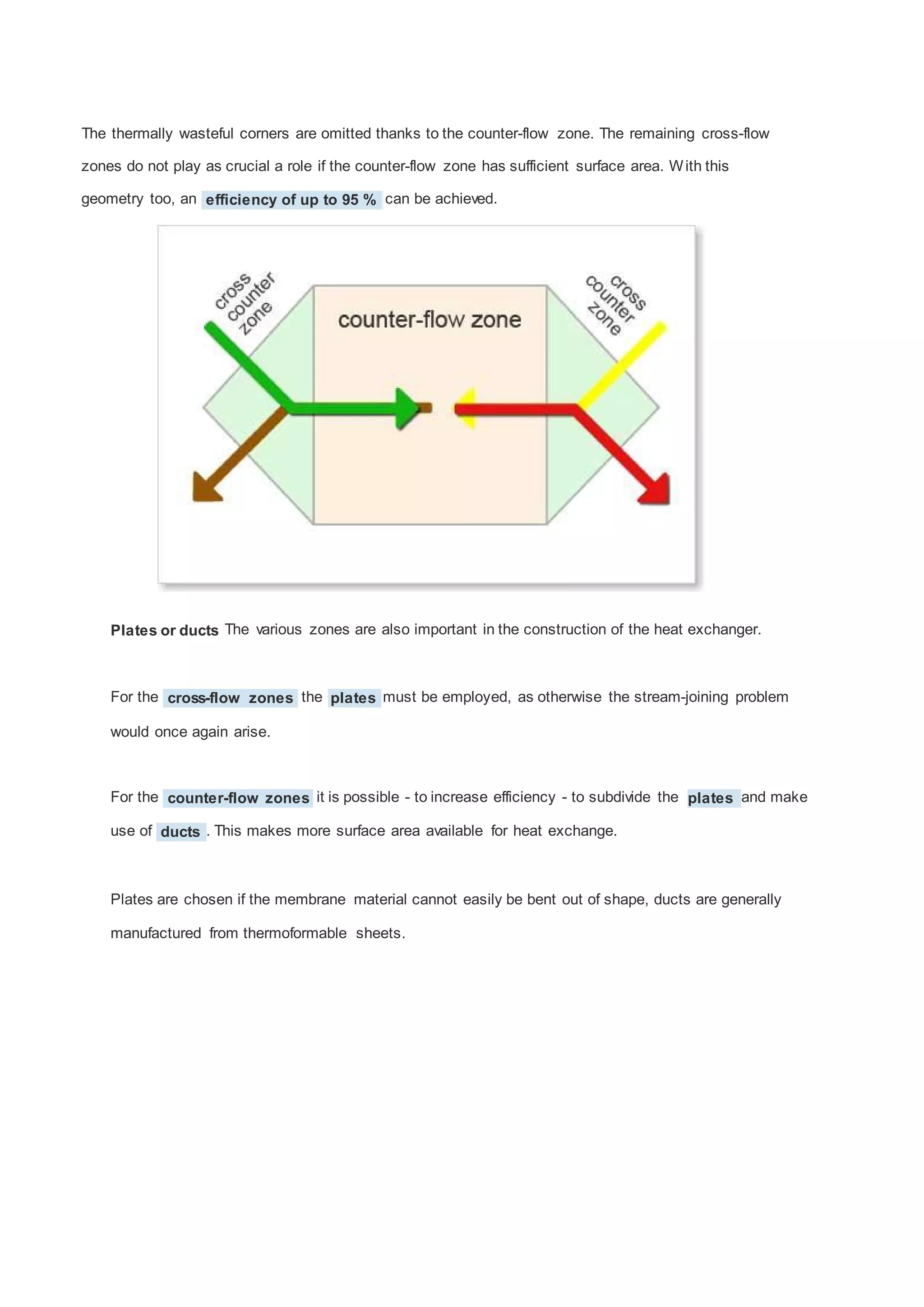

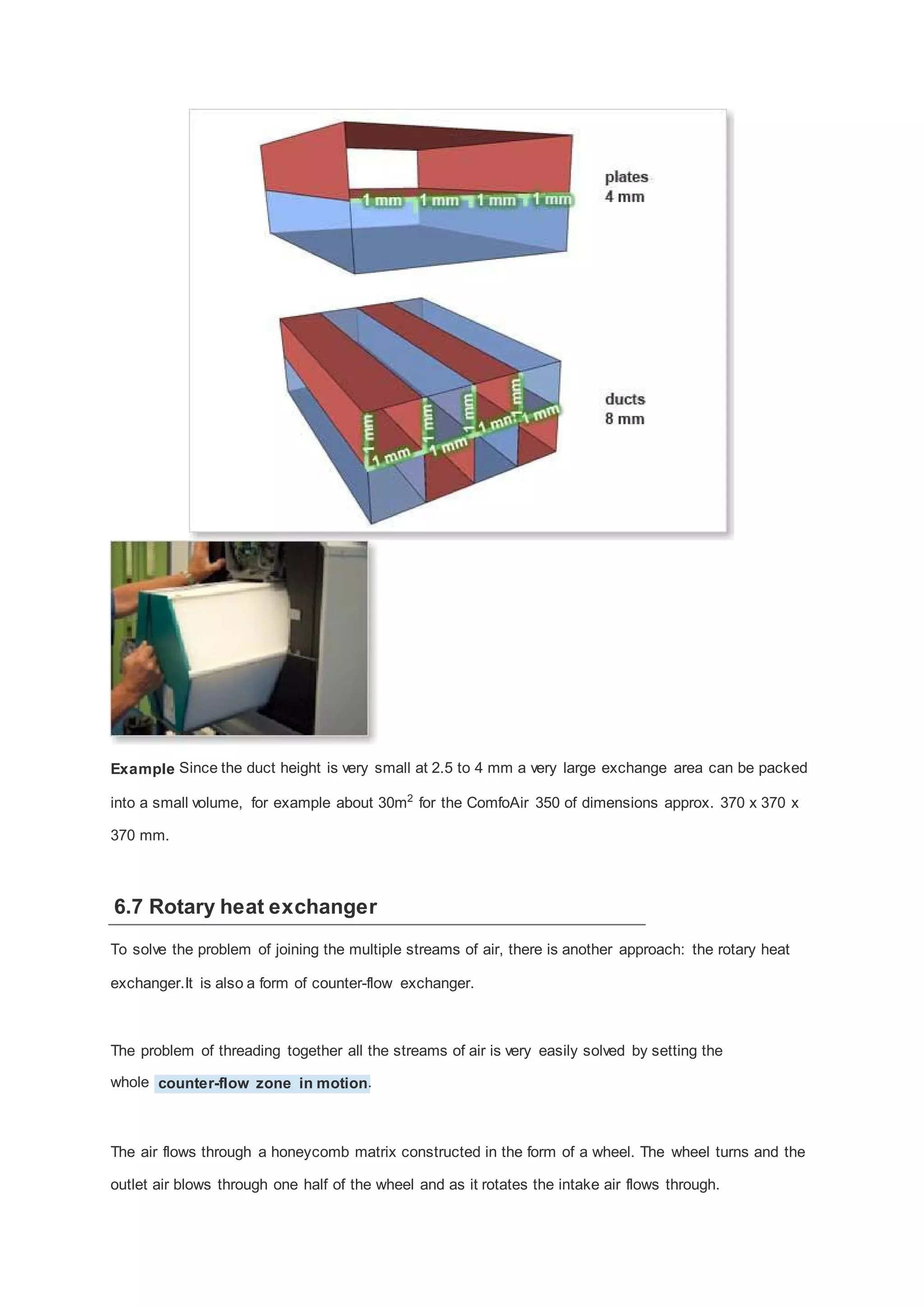

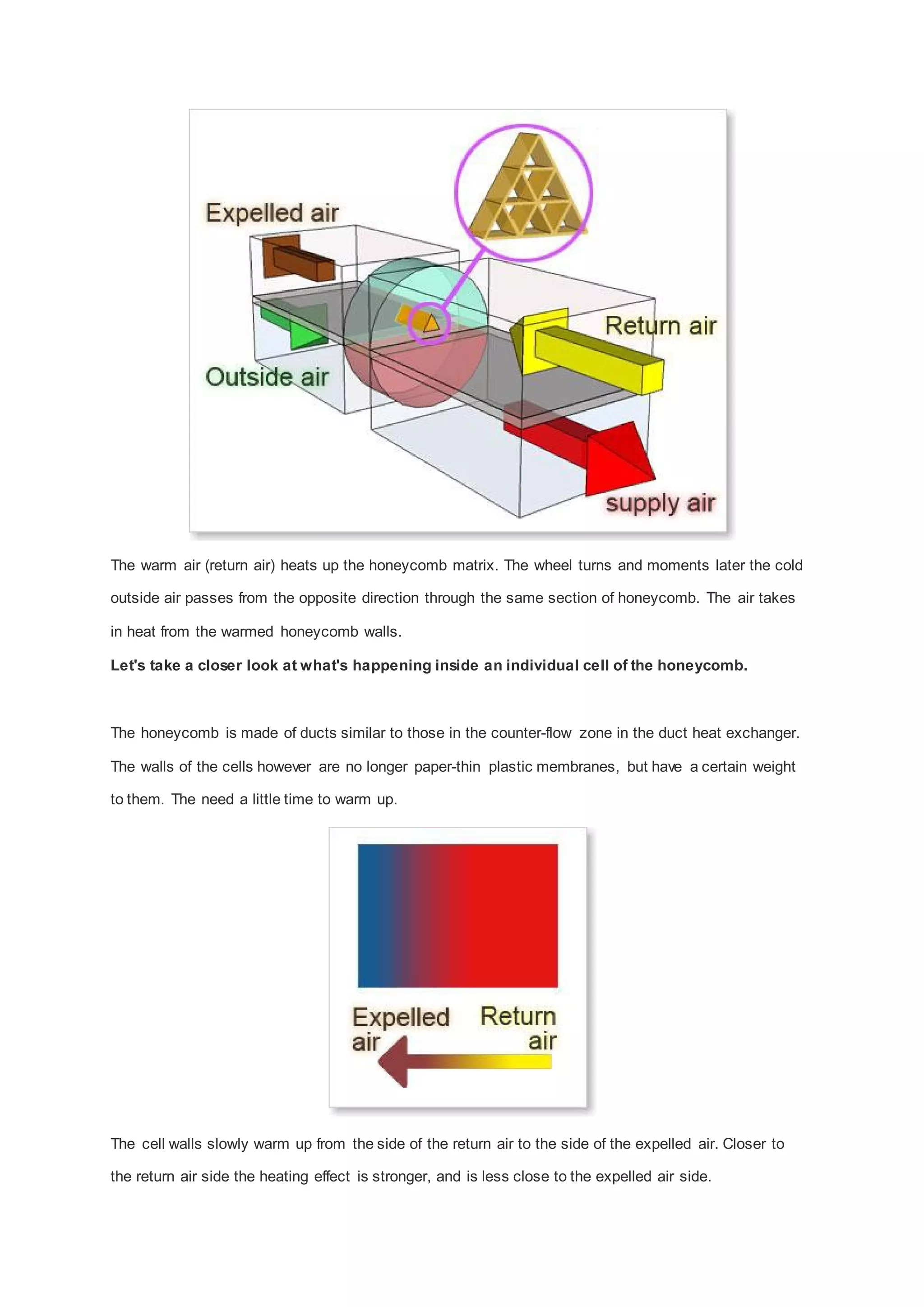

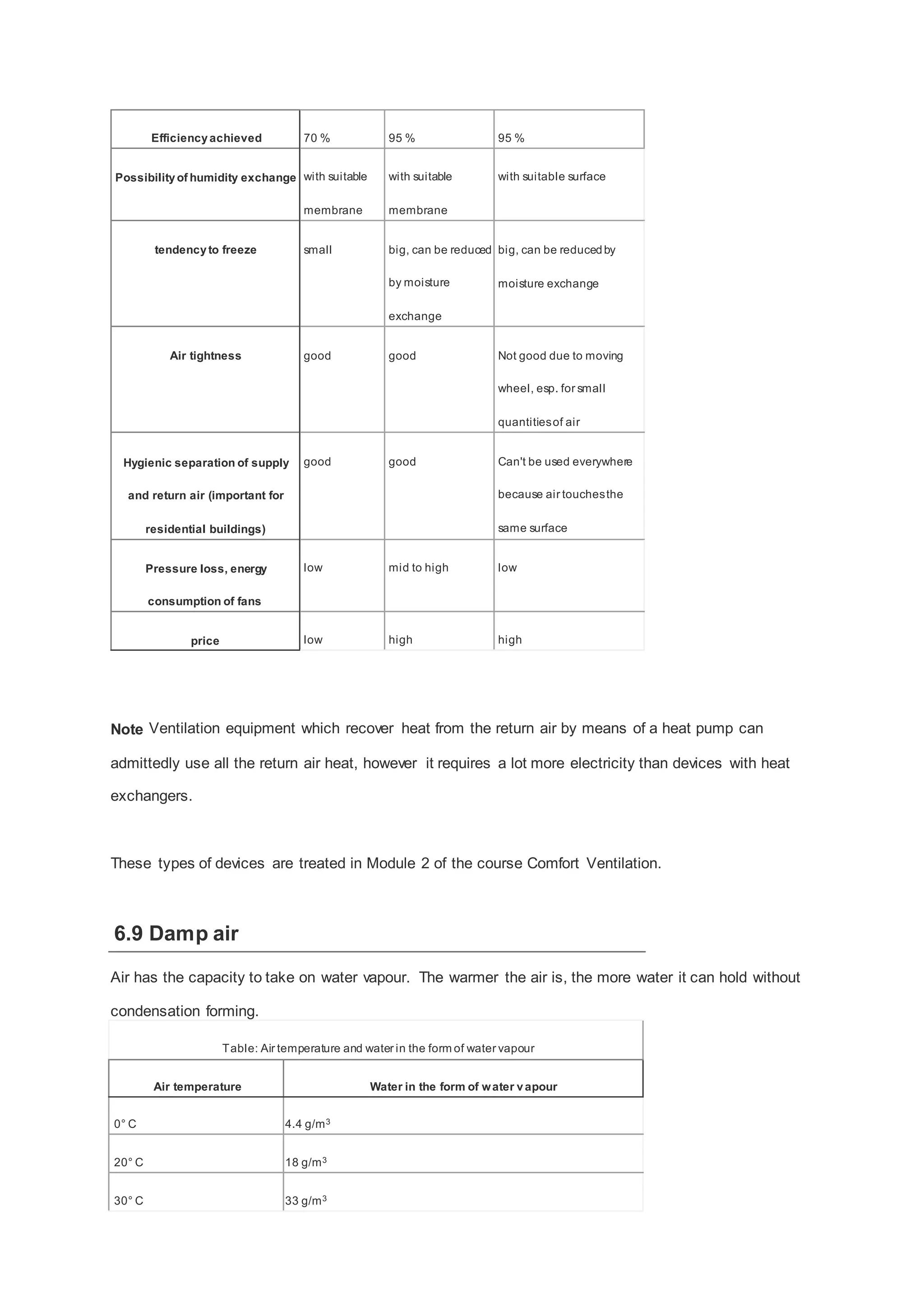

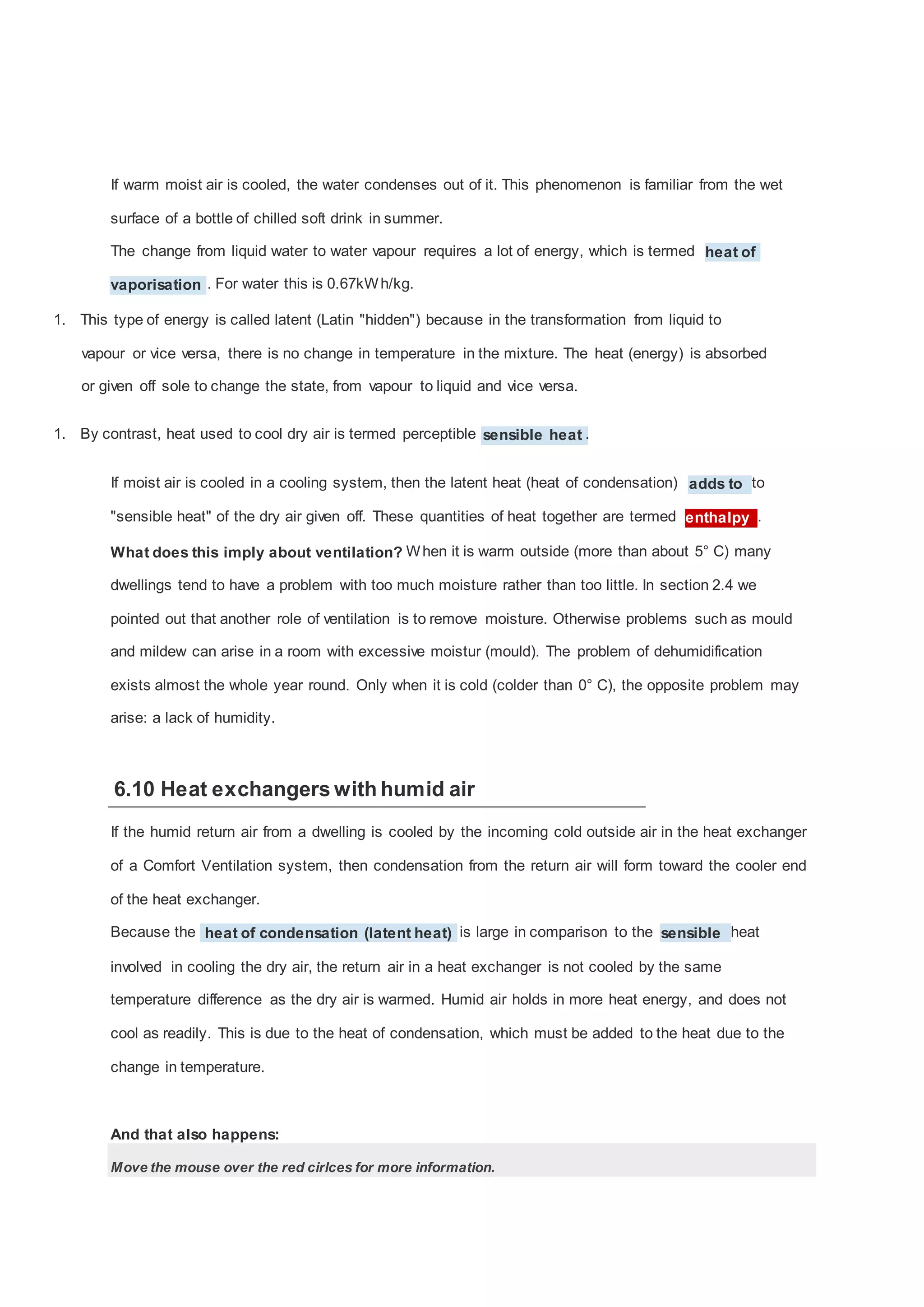

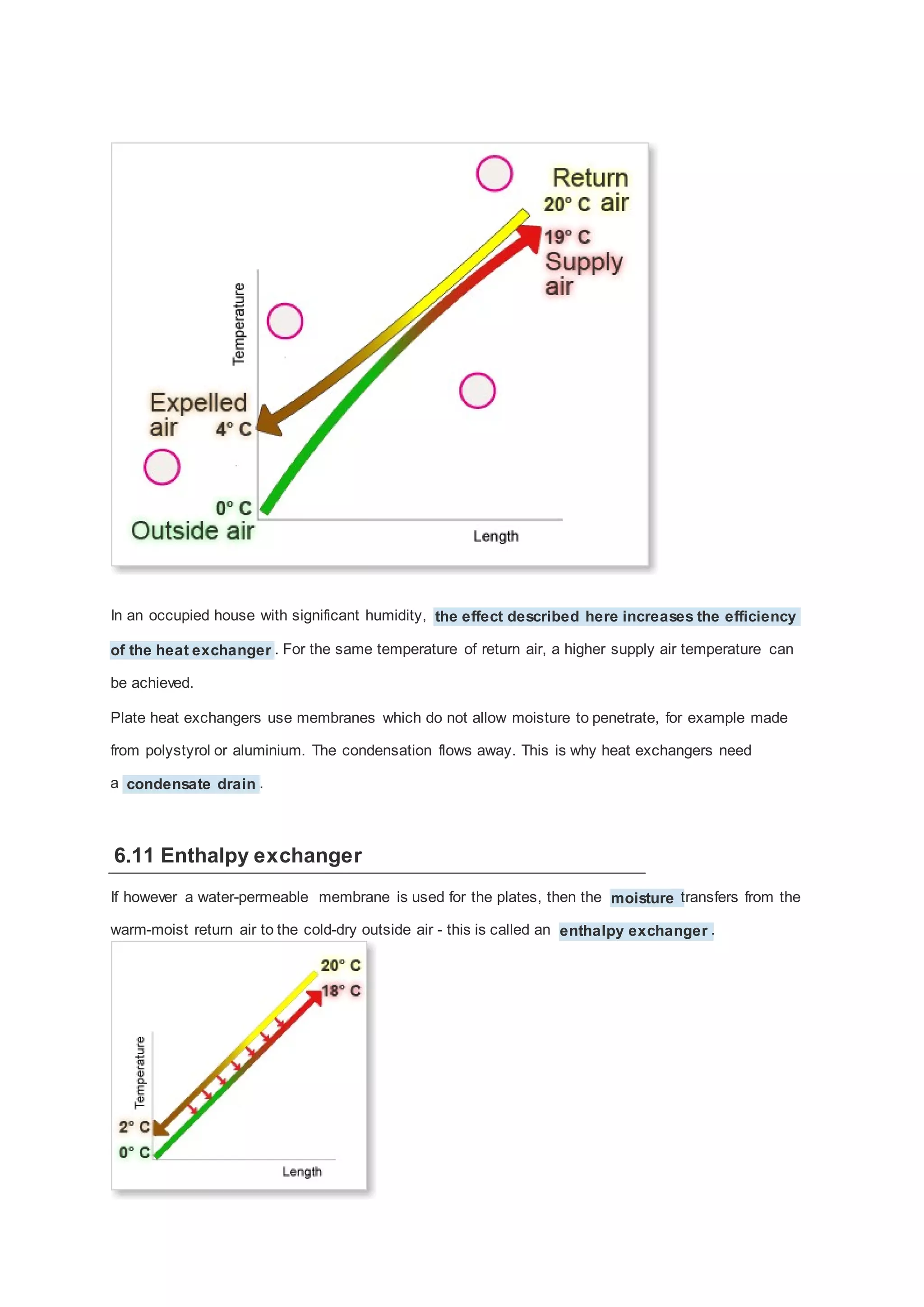

The document discusses the operation and types of heat exchangers used for heat recovery in ventilation systems, specifically focusing on cross-flow, counterflow, and cross-counter-flow designs. It explains how these systems optimize the transfer of heat from warmer exhaust air to cooler incoming air, enhancing energy efficiency, while also addressing challenges such as space requirements, air mixing, and humidity control. Additionally, it introduces enthalpy exchangers that allow moisture transfer to improve overall indoor air quality and comfort, especially in varying climate conditions.