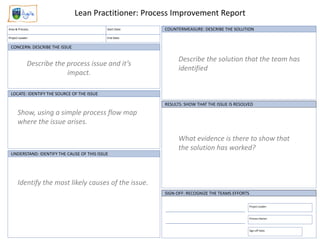

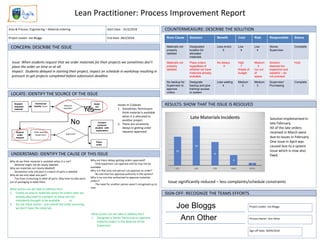

The document describes a process improvement project to address issues with material ordering at an engineering school. The project team identified two main issues: 1) technicians sometimes incorrectly believed materials were available when they had already been allocated to other projects due to poor labelling, and 2) there were occasional delays getting order requests approved due to relying on one person for approvals. To solve these, the team designated an area for pre-allocated materials and trained a backup to approve orders. As a result, late orders were reduced after implementing the solutions in late February, with only one issue in April due to an isolated system problem.