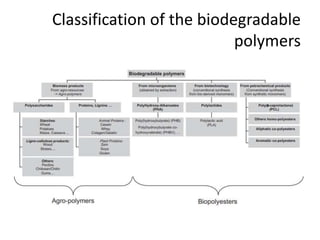

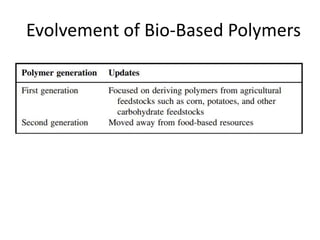

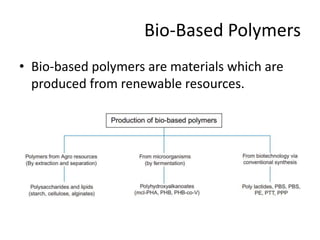

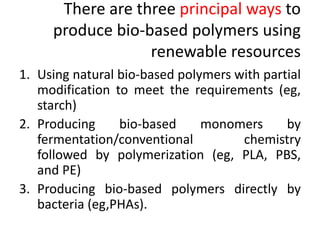

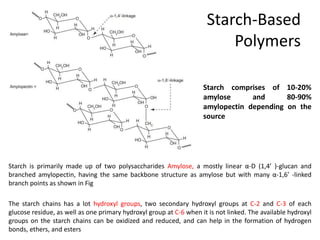

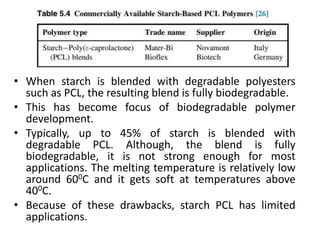

This document discusses types of biodegradable polymers. It begins by introducing the problems caused by non-biodegradable plastics and describes how biodegradable polymers are classified. There are three main ways to produce bio-based polymers: using modified natural polymers, producing monomers through fermentation then polymerization, and direct bacterial production. Bio-based polymers are divided into starch-based and cellulose-based. Starch-based polymers include thermoplastic starch, starch-synthetic polyester blends, starch-PBS/PBSA blends, and starch-PVOH blends. These starch-based polymers are used in applications where composting is effective and have properties suitable for various uses.