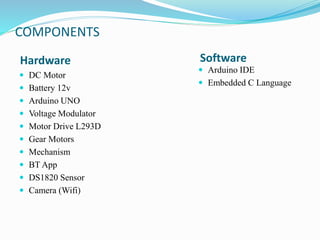

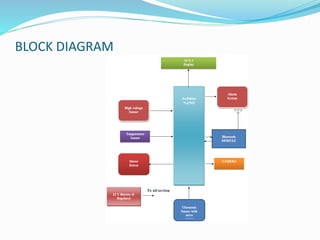

This project report describes the development of a robot for inspecting high voltage transmission lines. The robot uses cameras, sensors, and wireless communication to monitor and transmit data from transmission lines in a safe, cost-effective manner. It is powered by batteries and driven by motors controlled by an Arduino board. The robot aims to reduce costs and risks compared to manned inspection methods like helicopters or workers on the lines. Its components allow automated inspection and monitoring of transmission line parameters over WiFi in real-time.

![REFERENCE

[1] Hitachi High-Tech Fine Systems Corporation,’HiBot Corporation

reached the agreement with Hitachi High-Tech Group on the acceleration of

Transmission Line Inspection Business’ January 20, 2014

[2] Samuel Bouchard, ‘LineScout Robot Climbs on Live Power Lines to

Inspect Them’ 13 August 2010.

[3] Zheng LI and YI Ruan “Autonomous Inspection Robot for Power

Transmission Line Maintenance While Operating on the Overhead Ground

Wires” Academic press

[4] Yuvarani C et el. ‘TRANSMISSION LINE INSPECTION ROBOT’.

[5] Coleman Benson, ‘Drive Motor Sizing Tutorial’ February 1, 2012

TORKEL DANIELSSON, “Line Inspection Robot”.](https://image.slidesharecdn.com/transmissionlinerobot-220805072056-b02dd624/85/TRANSMISSION-LINE-ROBOT-pptx-13-320.jpg)