1. The document summarizes the training report of Mohammad Nour Khalil Sammour at Jordan Aeronautical Systems Company (JAC) from February to May 2010.

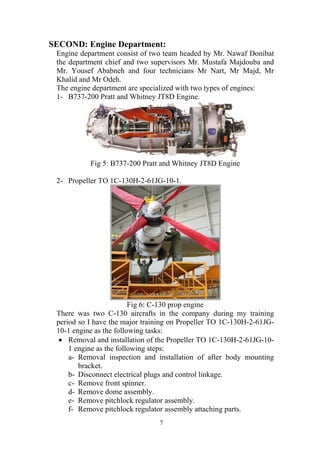

2. It describes the various departments at JAC including Ground Support Equipment (GSE), Engine, and Airframe. It outlines tasks completed in each department such as compressor washing, engine removal and installation, and fuel system installation.

3. The report concludes that the training provided valuable experience using tools, learning aircraft construction, engine systems, and the importance of following standards and manuals when completing engineering jobs.