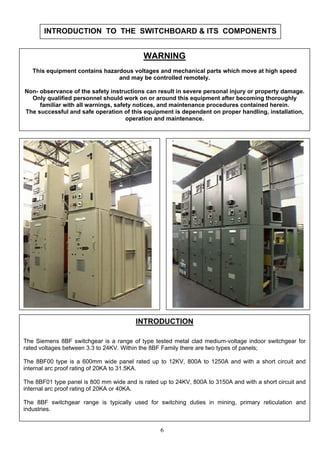

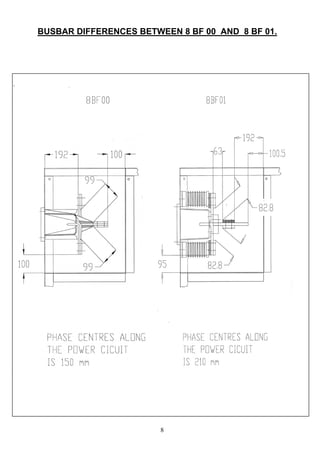

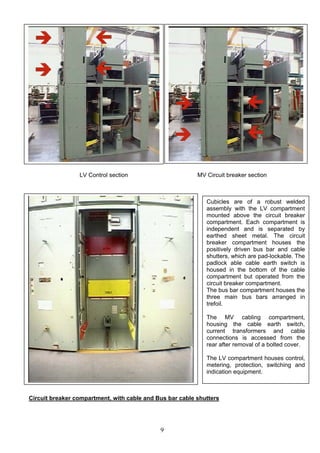

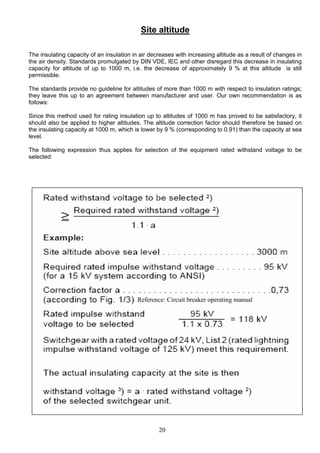

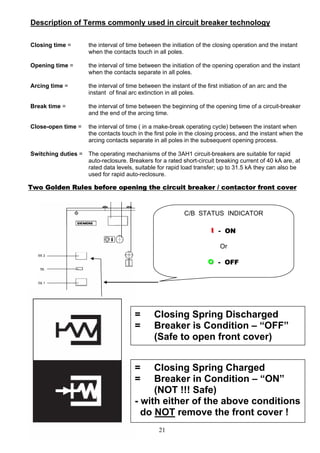

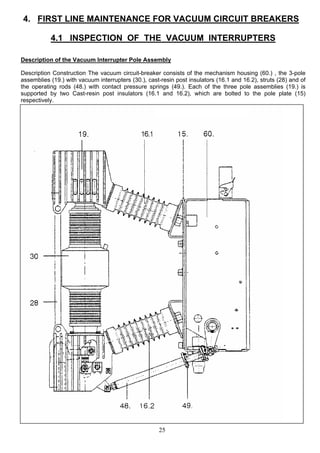

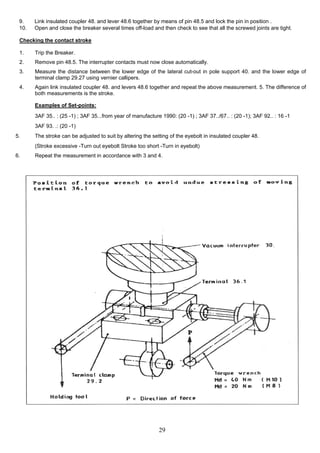

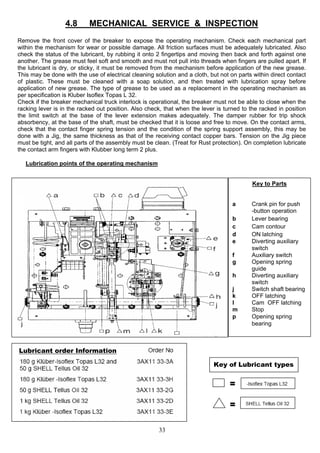

The document provides information about a product training course on medium voltage panels, vacuum circuit breakers, and contactors ranging from 3.3kV to 33kV. It covers the history of switching technology from oil to vacuum, the advantages of vacuum switching, applications of vacuum circuit breakers, components and design features of switchboards, and operational procedures for applying and removing cable earths.