This document provides details about the AE 6132 Total Quality Management course. The key points are:

- The course is 2 credits offered on Thursdays from 11:15am to 1:15pm.

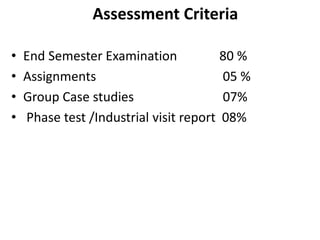

- Assessment includes an end semester exam (80%), assignments (5%), group case studies (7%), and a phase test/industrial visit report (8%).

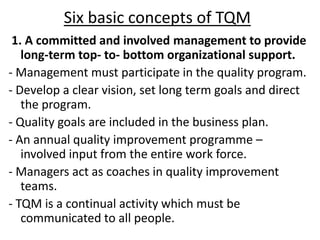

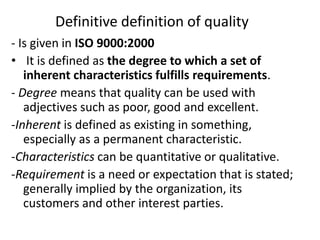

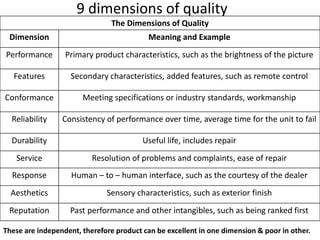

- The course contents cover topics such as quality concepts, quality auditing, quality management systems, control charts, and quality costs.

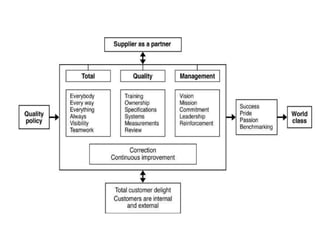

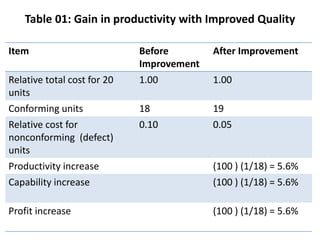

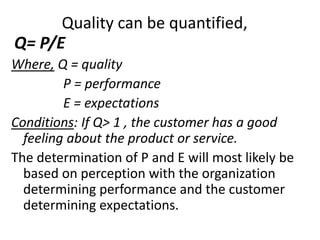

- The objective of the first lecture is to discuss the importance of total quality management.