1. Toyota Production System focuses on managing brilliant processes with average people to achieve brilliant results, unlike competitors who rely on brilliant people to manage broken processes.

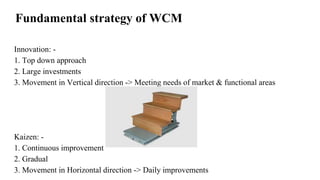

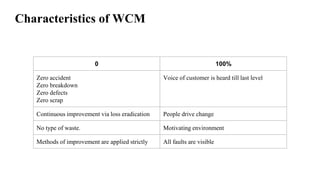

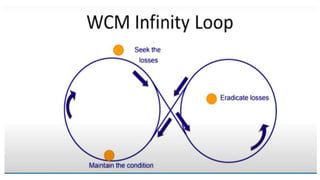

2. World Class Manufacturing introduced in 1984 focuses on continuous improvement, zero defects, breakdowns, waste, and accidents through techniques like kaizen and following a philosophy of innovation and gradual improvement.

3. The Toyota Production System originated in Japan and focuses on tools less than teams, consistent leadership, doing more than analyzing, and a deeper business philosophy understanding people and motivation.