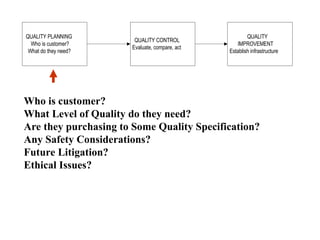

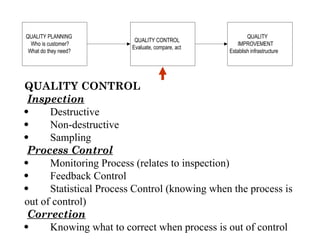

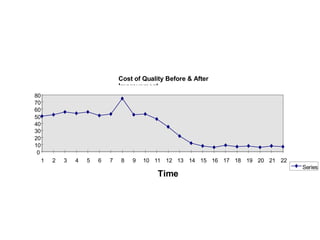

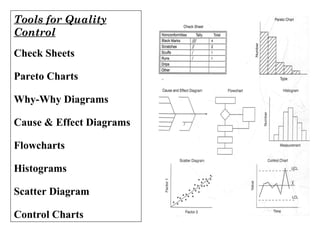

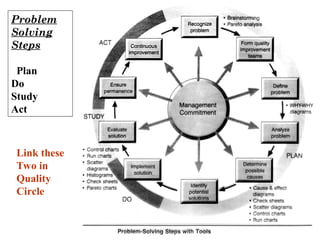

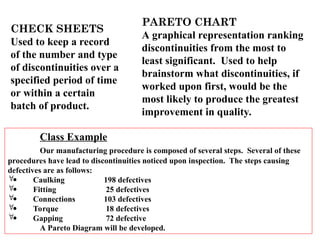

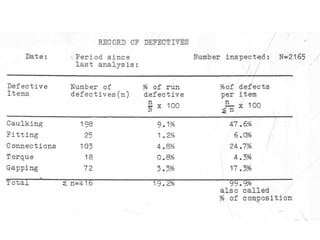

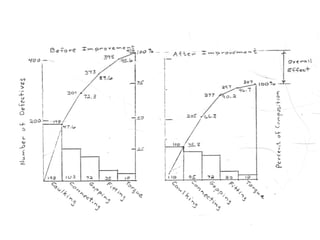

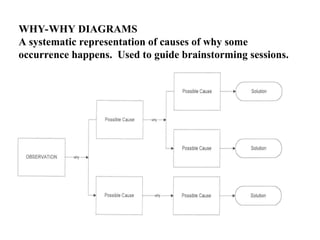

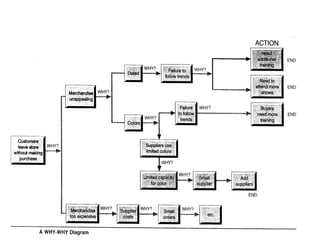

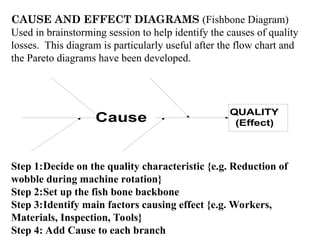

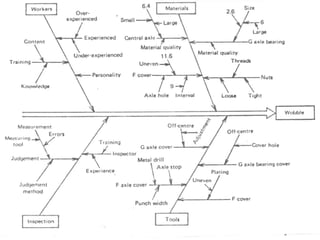

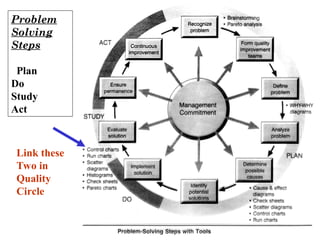

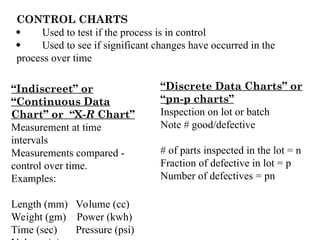

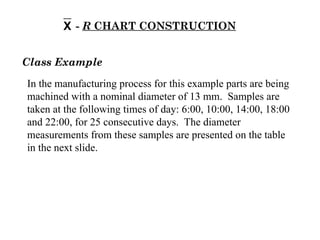

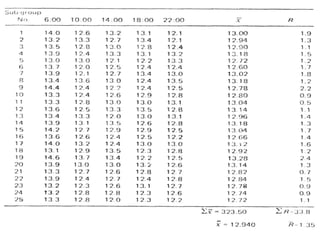

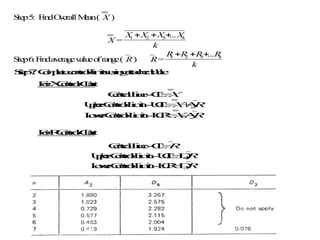

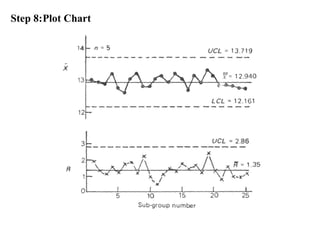

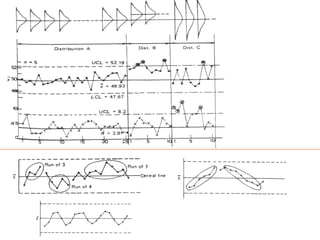

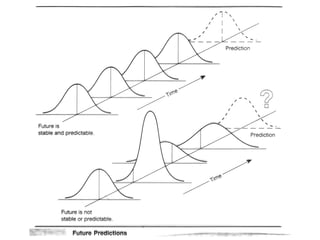

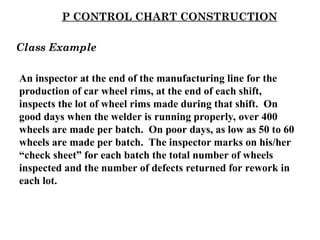

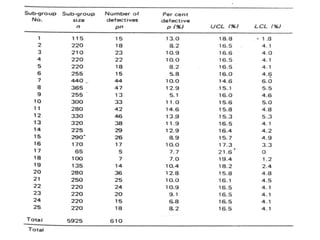

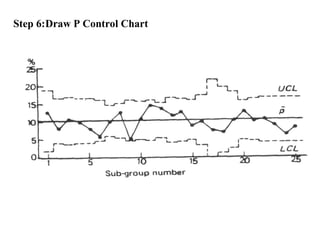

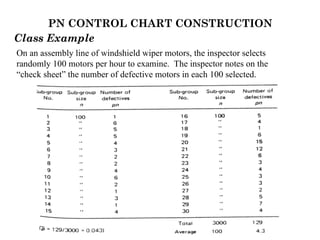

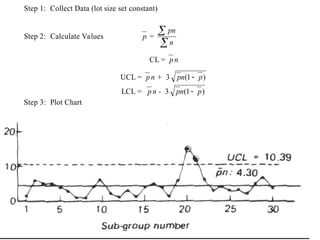

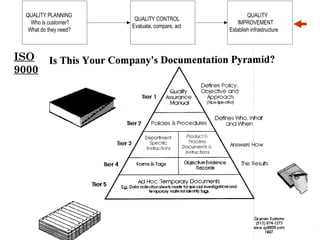

The document outlines key principles of total quality management, emphasizing continuous quality improvement through quality planning, control, and evaluation. It introduces various tools such as Pareto charts, flowcharts, and cause-and-effect diagrams for analyzing defects and ensuring process control. The text also discusses the importance of understanding customer needs and the overall cost of quality to enhance manufacturing processes.