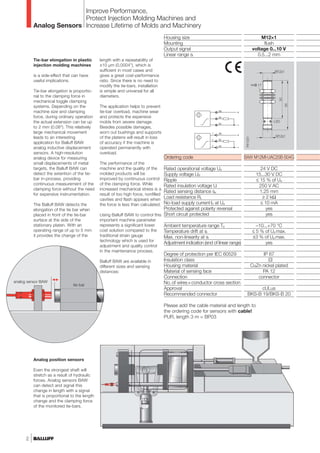

Analog sensors can detect small changes in the length of tie bars in plastic injection molding machines, allowing continuous monitoring of clamping force without expensive instrumentation. The sensors measure elongation of up to 2mm as the tie bar stretches under hydraulic forces, providing feedback to prevent overload and protect molds. This lower cost solution improves machine performance and molded product quality by ensuring the clamping force is properly controlled.