EN60454-3-1.PDF

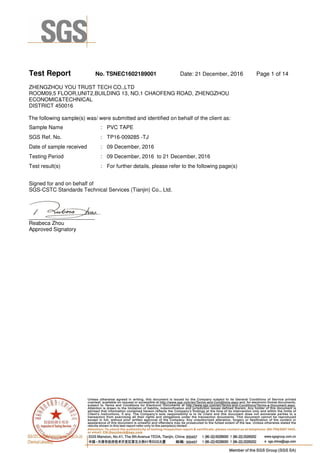

- 1. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 1 of 14 ZHENGZHOU YOU TRUST TECH CO.,LTD ROOM09,5 FLOOR,UNIT2,BUILDING 13, NO.1 CHAOFENG ROAD, ZHENGZHOU ECONOMIC&TECHNICAL DISTRICT 450016 The following sample(s) was/ were submitted and identified on behalf of the client as: Sample Name : PVC TAPE SGS Ref. No. : TP16-009285 -TJ Date of sample received : 09 December, 2016 Testing Period : 09 December, 2016 to 21 December, 2016 Test result(s) : For further details, please refer to the following page(s) Signed for and on behalf of SGS-CSTC Standards Technical Services (Tianjin) Co., Ltd. ______________________ Reabeca Zhou Approved Signatory

- 2. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 2 of 14 Summary of Results: No. Test Item Test Method Result Conclusion 1 Corrosive Sulfur Resistance BS EN 60454-2:2007 Section 7.5 Copper rod(adhesive side downward) No visible staining / Copper rod(adhesive side upward) No visible staining 2 Dielectric Strength EN 60454-3- 1:1998+A1:2001 & BS EN 60454-2:2007 Section 17 & IEC 60243-1:2013 Short- time (Rapid-rise) Test 61.3 kV/mm Pass 3 Dielectric Strength after Humidity Conditioning EN 60454-3- 1:1998+A1:2001 & BS EN 60454-2:2007 Section 18 & IEC 60243-1:2013 Short- time (Rapid-rise) Test 63.6 kV/mm Pass 4 Low temperature properties EN 60454-3- 1:1998+A1:2001 & BS EN 60454-2:2007 Section 9 Flexibility No cracking, no unwinding Pass Electric breakdown No breakdown Pass 5 180º Peel Strength EN 60454-3- 1:1998+A1:2001 & BS EN 60454-2:2007 Section 11 Method A 2.0N/10mm Pass

- 3. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 3 of 14 No. Test Item Test Method Result Conclusion 6 Adhesion to backing at low temperature With reference to EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 12 & client’s requirement 2.9N/10mm Pass 7 Flame test EN 60454-3- 1:1998+A1:2001 & BS EN 60454-2:2007 Section 20 Flame retardant Pass 8 Length ASTM D1000-10 Section 30-32 Method A 20.7m / 9 Shear adhesion to backing after liquid immersion EN 60454-3- 1:1998+A1:2001 & BS EN 60454-2:2007 Section 13 20.8N Pass

- 4. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 4 of 14 No. Test Item Test Method Result Conclusion 10 Tensile Test EN 60454-3- 1:1998+A1:2001 & BS EN 60454-2:2007 Section 8 Breaking Strength 229N/10mm per millimetre of tape thickness Pass Elongation at Break 255% Pass 11 Thickness EN 60454-3- 1:1998+A1:2001 & BS EN 60454-2:2007 Section 4 0.128mm Pass 12 Width EN 60454-3- 1:1998+A1:2001 & BS EN 60454-2:2007 Section 5 Method A 18.4mm / Note: Pass : Meet the requirements; Fail : Does not meet the requirements; / : Not Apply to the judgment. Original Sample Photo:

- 5. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 5 of 14 1. Test item: Corrosive sulfur resistance Sample description: See photo Test method: BS EN 60454-2:2007 Section 7.5 Test condition: Copper rod diameter: 6 mm, length: 75 mm Wind the copper rods(as follows)→100±2 ℃, 16 h Test result(s): Test item Test results Corrosive sulfur resistance Copper rod(adhesive side downward) No visible staining Copper rod(adhesive side upward) No visible staining Note: Test specimens were cut from the sample.

- 6. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 6 of 14 2. Test Item: Dielectric Strength Sample Description: See photo Test Method: EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 17 & IEC 60243-1:2013 Short-time (Rapid-rise) Test Test Condition: Precondition: 23 ± 2 ℃, 50 ± 5 % RH, 48 h Thickness of specimen: 0.127 mm Test condition: 23 ± 2 ℃, 50 ± 5 % RH Surround medium: Air Similar electrode: Electrode diameter: 6.4 mm Frequency of voltage application: 50 Hz Rate-of-rise: 500 V/s Test Result: Test Item Test Result Requirement in EN 60454-3- 1:1998+A1:2001 Conclusion Dielectric Strength 61.3 kV/mm ≥40 kV/mm Pass Note: Test specimens were cut from the sample.

- 7. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 7 of 14 3. Test Item: Dielectric Strength after Humidity Conditioning Sample Description: See photo Test Method: EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 18 & IEC 60243-1:2013 Short-time (Rapid-rise) Test Test Condition: Precondition: 23 ± 2 ℃, 93 ± 2 % RH, 24 h Thickness of specimen: 0.132 mm Test condition: 23 ± 2 ℃, 50 ± 5 % RH Surround medium: Air Similar electrode: Electrode diameter: 6.4 mm Frequency of voltage application: 50 Hz Rate-of-rise: 500 V/s Test Result: Test Item Test Result Requirement in EN 60454-3- 1:1998+A1:2001 Conclusion Dielectric Strength 63.6 kV/mm ≥35 kV/mm Pass Note: Test specimens were cut from the sample.

- 8. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 8 of 14 4. Test item: Low temperature properties Sample description: See photo Test method: EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 9 Test condition: Flexibility: Precondition: -18 ℃, 3 h Test temperature: -18 ℃ Bent angle: 180° Mandrel diameter: 8 mm Electric breakdown: Precondition: After flexibility test→23±2 ℃, 4h→Immerse the bent portion in tap water, 23±2℃, 1h Surround medium: Tap water Test temperature: 23±2 ℃ Test voltage: AC, 1500 V Electrification time: 1min Test result(s): Test item Test Result Requirement in EN 60454-3- 1:1998+A1:2001 Conclusion Flexibility No cracking, no unwinding No cracking, no unwinding Pass Electric breakdown No breakdown No breakdown Pass Note: Test specimens were cut from the sample.

- 9. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 9 of 14 5. Test Item: 180º Peel Strength Sample Description: See photo Test Method: EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 11 Method A Test Condition: Specimen width: 18.4mm Testing speed: 300mm/min Lab Environmental Condition: (23±2)℃, (50±5)%RH Test Result: Test Item Test Result Requirement in EN 60454-3- 1:1998+A1:2001 Conclusion 180º Peel Strength (to steel panel) 2.0N/10mm ≥1.8N/10mm Pass Note: Test specimens were cut from the sample. 6. Test Item: Adhesion to backing at low temperature Sample Description: See photo Test Method: With reference to EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 12 & client’s requirement Test Condition: Precondition: -10℃, 2h → Prepare the specimen at -10℃ → -10℃, 17h → Take out and do the 180º Peel adhesion test immediately Specimen width: 18.4mm Testing speed: 300mm/min Lab Environmental Condition: (23±2)℃, (50±5)%RH Test Result: Test Item Test Result Client’s requirement Conclusion Adhesion to backing at low temperature 2.9N/10mm ≥1.5N/10mm Pass Note: Test specimens were cut from the sample.

- 10. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 10 of 14 7. Test Item: Flammability Sample Description: See photo Test Method: EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 20 Test Condition: Specimen width: 18mm Metal wire diameter: 3.5mm Test Result: Specimen No. 1 2 3 Number of Flame application 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 Flame time after each application (s) 1.0 0 0 0 1.0 0 2.1 0 1.0 1.0 1.0 0 0 1.0 0 Whether or not any specimen continues to flame longer than 60 s after application of the gas flame No No No Whether or not any specimen shows more than 25% of the indicator flag burned away or charred No No No Whether or not any specimen emits flaming or glowing particles or flaming drops at any time that ignite the cotton No No No Judgment a) Flame retardant. (See note 1) b) Can’t convey flame along its length. (See note 2) c) Can’t convey flame to combustible materials in its vicinity. (See note 3) Requirement in EN 60454-3-1:1998+A1:2001: Flame retardant Conclusion: Pass

- 11. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 11 of 14 Note: 1. If the specimen shows less than 25 % of the indicator flag burned or charred (soot that can be removed with a cloth or fingers and brown scorching is to be ignored), does not emit flaming or glowing particles or flaming drops at any time that ignite the cotton on the burner, wedge, or floor of the enclosure (flameless charring of the cotton shall be ignored) and continues to flame less than 60 s after application of the gas flame, the tape shall be judged flame retardant. 2. If the specimen shows more than 25 % of the indicator flag burned or charred (soot that can be removed with a cloth or fingers and brown scorching is to be ignored) after any of the five applications of flame, the tape is to be judged capable of conveying flame along its length. 3. If the specimen emits flaming or glowing particles or flaming drops at any time that ignites the cotton on the burner, wedge, or floor of the enclosure (flameless charring of the cotton shall be ignored), the tape is judged capable of conveying flame to combustible materials in its vicinity. 4. Test specimens were cut from the sample.

- 12. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 12 of 14 8. Test Item: Length Sample Description: See photo Test Method: ASTM D1000-10 Section 30~32 Method A Test Condition: Measured by digital balance Lab Environment Condition: (23±2)℃, (50±5)%RH Test Result: Test Item Test Result Length 20.7m Note: Test specimens were cut from the sample. 9. Test Item: Shear adhesion to backing after liquid immersion Sample Description: See photo Test Method: EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 13 Test Condition: Precondition: Immerse in water, 23±2℃, 16h → Wipe off water, do the test after 5min Adhesion area: 12×12mm 2 Testing speed: 300mm/min Lab Environmental Condition: (23±2)℃, (50±5)%RH Test Result: Test Item Test Result Requirement in EN 60454-3- 1:1998+A1:2001 Conclusion Shear adhesion to backing after liquid immersion 20.8N ≥18N Pass Note: Test specimens were cut from the sample.

- 13. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 13 of 14 10. Test Item: Tensile Test Sample Description: See photo Test Method: EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 8 Test Condition: Specimen width: 18.4mm Specimen thickness: 0.128mm Testing speed: 300mm/min Grip separation: 100mm Lab Environmental Condition: (23±2)℃, (50±5)%RH Test Result: Test Item Test Result Requirement in EN 60454-3- 1:1998+A1:2001 Conclusion Breaking Strength 229N/10mm per millimetre of tape thickness ≥150N/10mm per millimetre of tape thickness Pass Elongation at Break 255% ≥125% Pass Note: Test specimens were cut from the sample.

- 14. Test Report No. TSNEC1602189001 Date: 21 December, 2016 Page 14 of 14 11. Test Item: Thickness Sample Description: See photo Test Method: EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 4 Test Condition: Pressure: 54.4kPa Nominal thickness: 0.13mm (Provided by client) Lab Environmental Condition: (23±2)℃, (50±5)%RH Test Result: Test Item Test Result Client’s requirement Conclusion Thickness 0.128mm 0.13±0.025mm Pass Note: Test specimens were cut from the sample. 12. Test Item: Width Sample Description: See photo Test Method: EN 60454-3-1:1998+A1:2001 & BS EN 60454-2:2007 Section 5 Method A Lab Environmental Condition: (23±2)℃, (50±5)%RH Test Result: Test Item Test Result Width 18.4mm Note: Test specimens were cut from the sample. Appendix information: The above test was carried out by a SGS internal laboratory. ******** End of report********