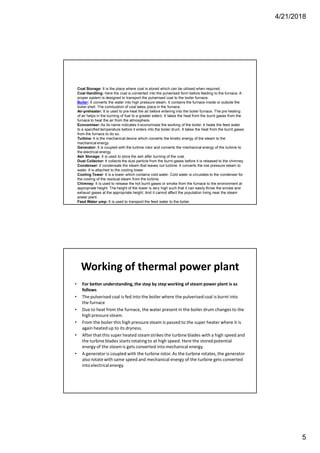

The document discusses the various types of thermal power plants, including coal, oil, gas, and diesel-fired plants, focusing on their components, operation, and site selection criteria. Key factors for site selection include land cost, population density, water and fuel availability, and transportation facilities, while also outlining the merits and demerits of thermal power generation. Additionally, it explains the working of thermal power plants and highlights components such as boilers, turbines, generators, and cooling systems.