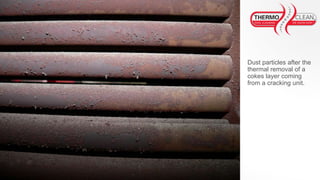

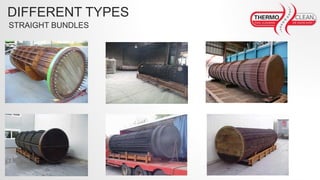

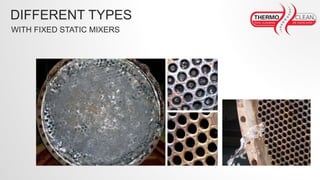

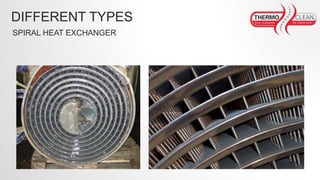

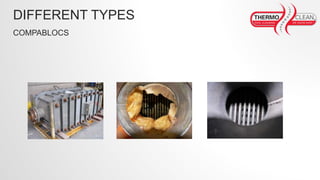

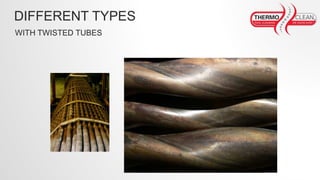

Thermal cleaning is a method to thoroughly clean heat exchangers and other industrial equipment. It can remove residue from inside and between tubes, as well as other hard to reach areas. Examples show that thermal cleaning removed over 1 kg of residue from a heat exchanger after conventional cleaning, and another 163 kg from bundles that were previously declared clean. Thermal cleaning is suitable for various types of heat exchangers and industrial components to help extend equipment lifetime and reduce energy costs through more effective cleaning.