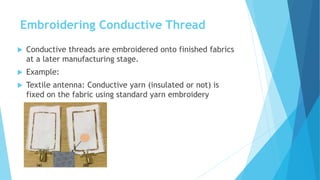

The document discusses the significance of electrical interconnections in smart textiles, highlighting their role in wearable device functionality and overall performance. It outlines various integration methods, including sewing flexible cables, weaving with conductive yarns, and embroidering conductive threads. Key factors for effective interconnections include comfort, reliability, and resistance to wear and washing.