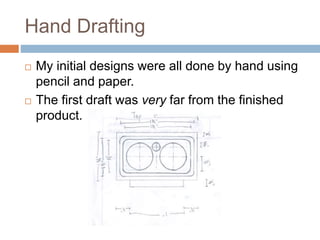

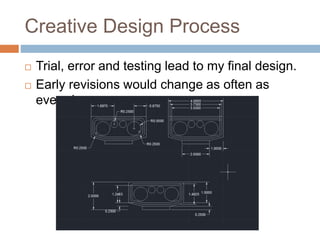

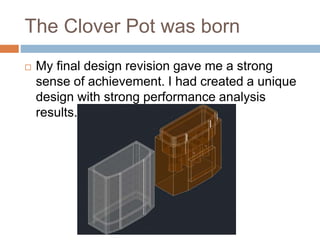

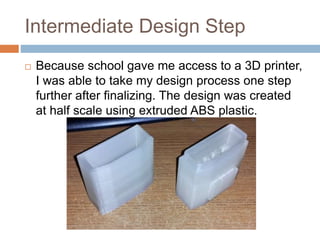

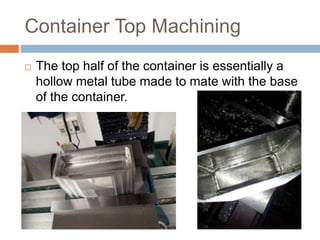

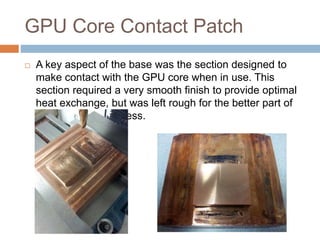

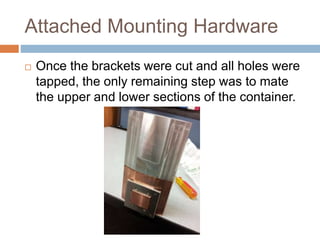

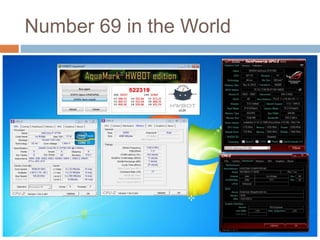

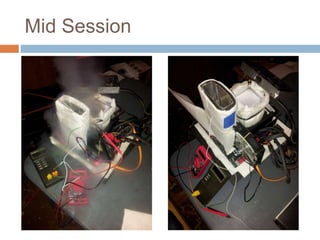

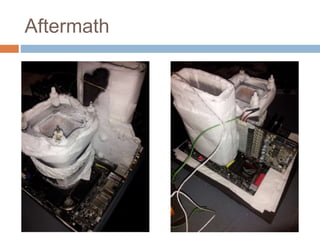

The document describes the design and creation of a custom liquid nitrogen GPU cooling container called the Clover Pot. It discusses the author's history with overclocking and benchmarking computers, which led them to build their own container to push components further. The summary describes the design and machining process, including CAD design, 3D printing prototypes, and CNC machining of aluminum and copper parts. Benchmarking tests with the completed Clover Pot achieved a top 69 ranking globally in the Aquamark3 GPU benchmark.