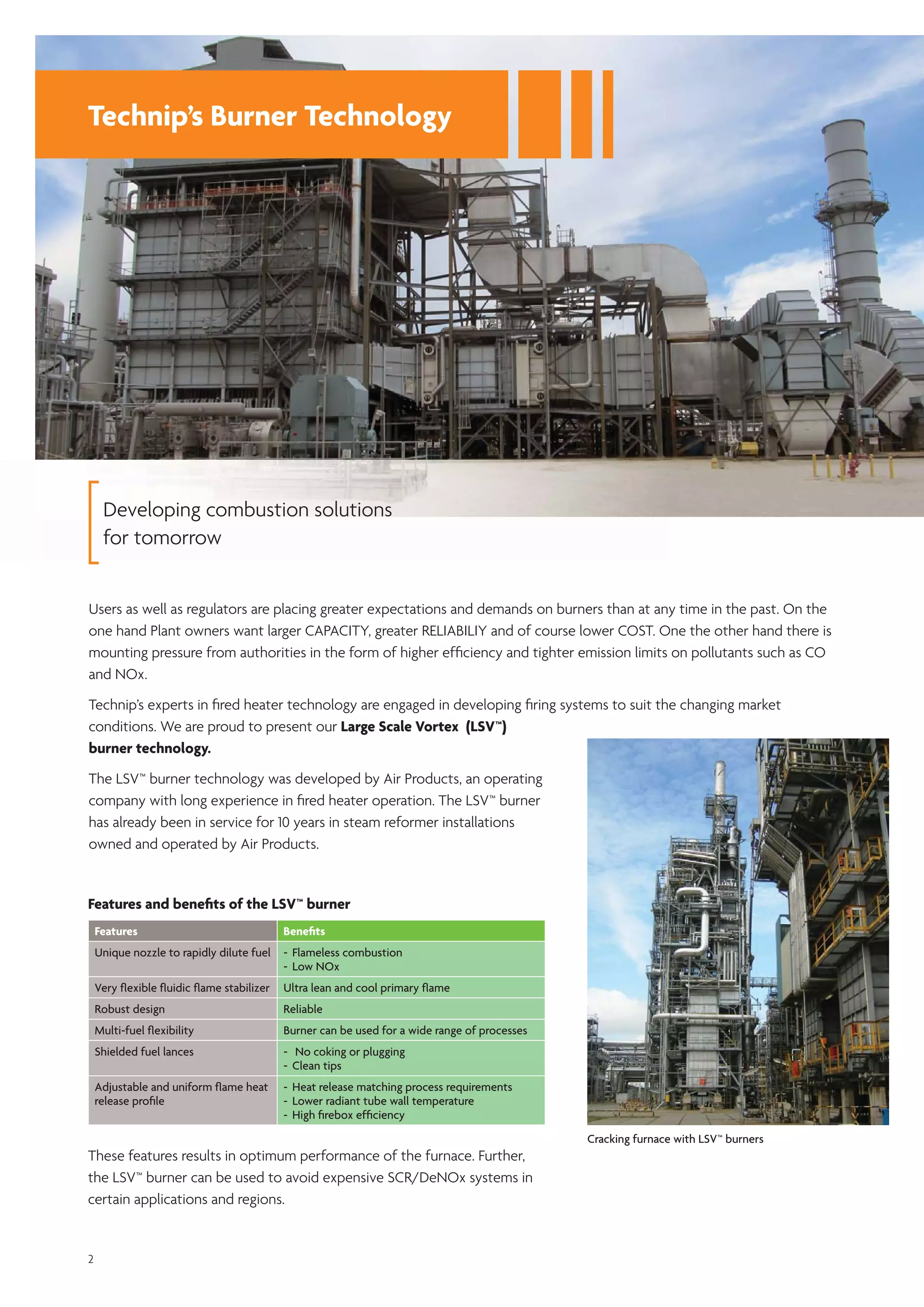

The document describes Technip's Large Scale Vortex (LSVTM) burner technology. It provides low NOx emissions and reliable combustion while meeting demands for increased capacity, efficiency, and emissions regulations. The LSVTM burner was developed by Air Products and has been in successful operation for 10 years. It features unique nozzle design and flexible flame stabilization to enable lean, cool combustion and uniform heat release. This results in ultra-low NOx and increased equipment lifetime. The LSVTM burner can be used across various process applications and configurations.