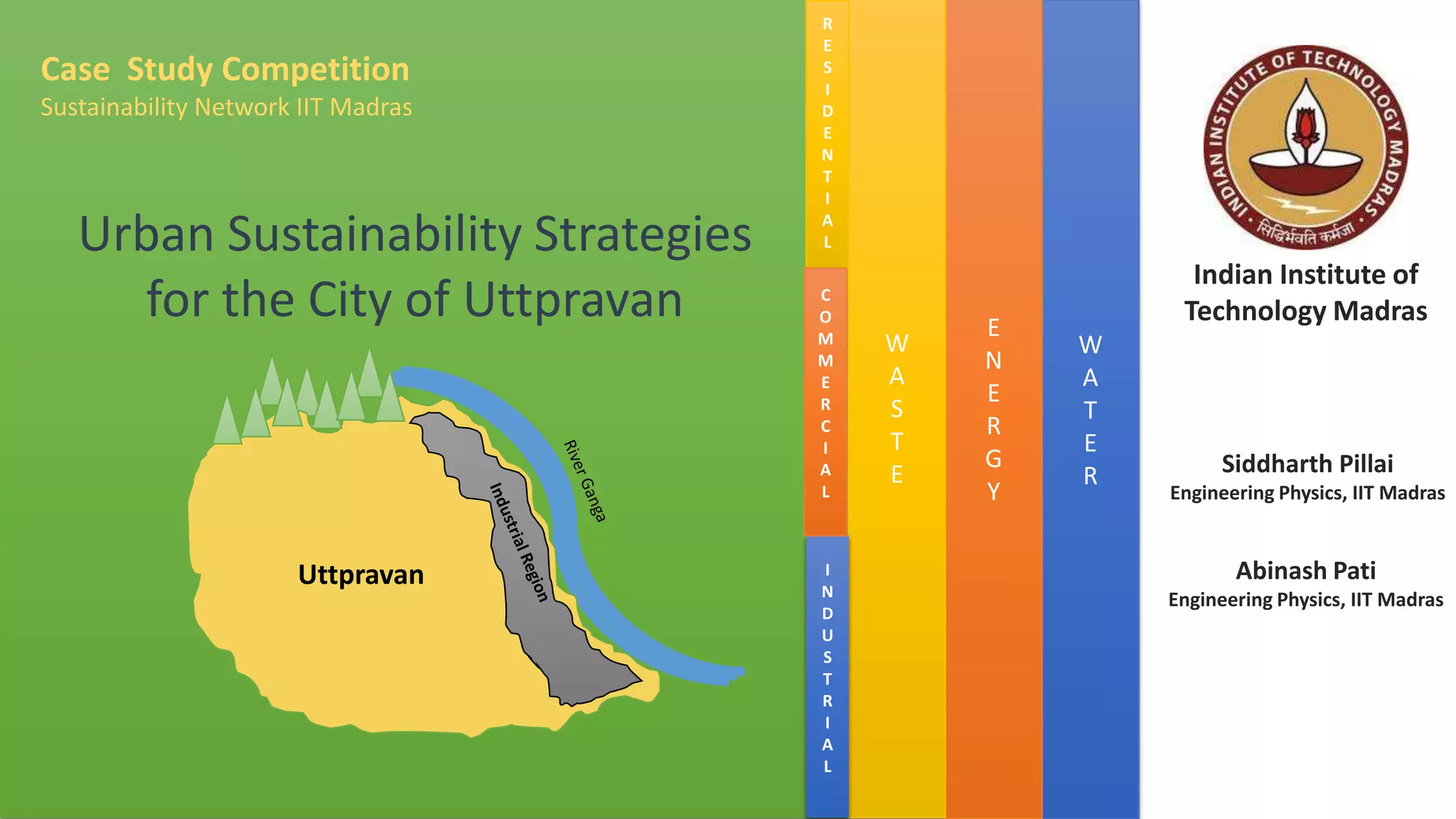

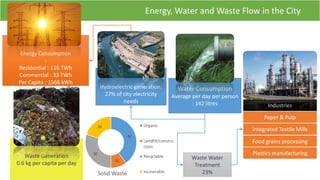

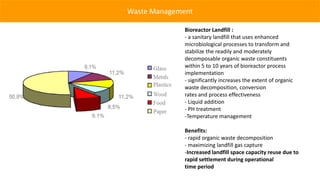

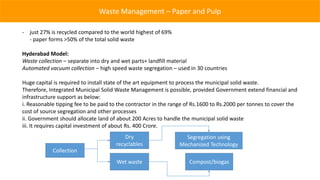

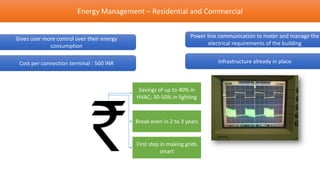

The document discusses urban sustainability strategies for the city of Uttpravan, India. It analyzes the city's energy consumption, water usage, and waste generation. It then provides recommendations to improve management of energy, water, and waste in key industries like paper/pulp, textiles, food processing, and plastics manufacturing. Suggestions include using bioreactors in landfills, recycling programs, wastewater treatment plants, and converting waste to energy through processes like anaerobic digestion.