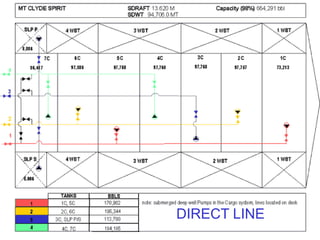

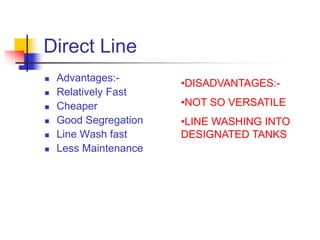

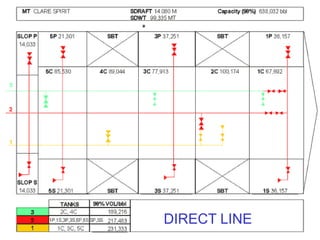

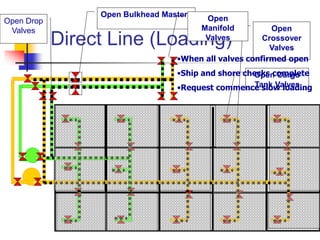

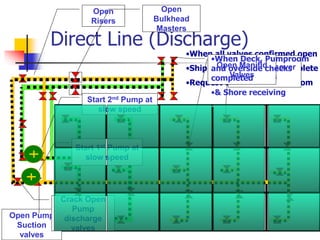

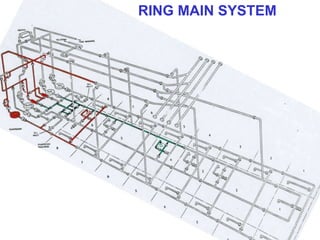

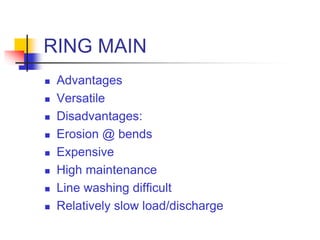

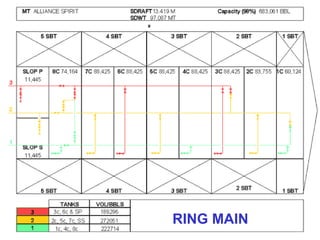

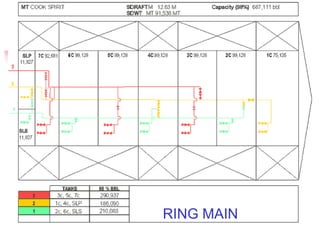

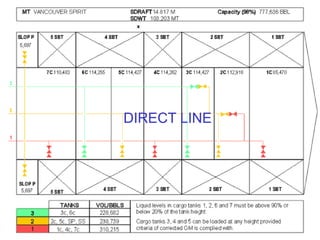

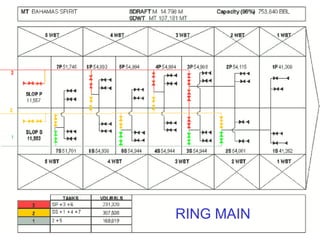

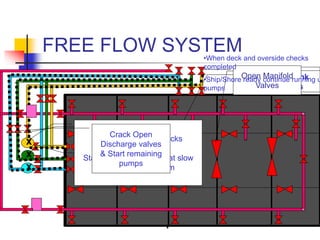

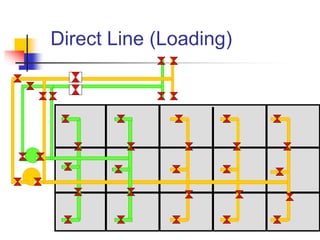

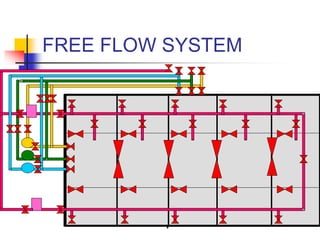

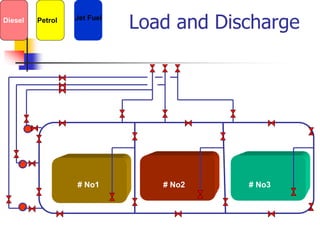

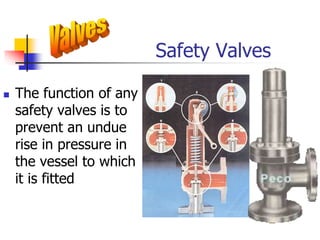

The document discusses different types of tanker pipeline systems used to load and discharge cargo on tankers. It describes direct line systems as relatively fast and cheaper but less versatile, with line washing only going to designated tanks. Ring main systems are more versatile but more expensive and difficult to maintain. Free flow systems are the fastest for loading and discharging but provide poor cargo segregation and require vessels to also have a pipeline system. Safety valves prevent undue pressure rises in vessels.