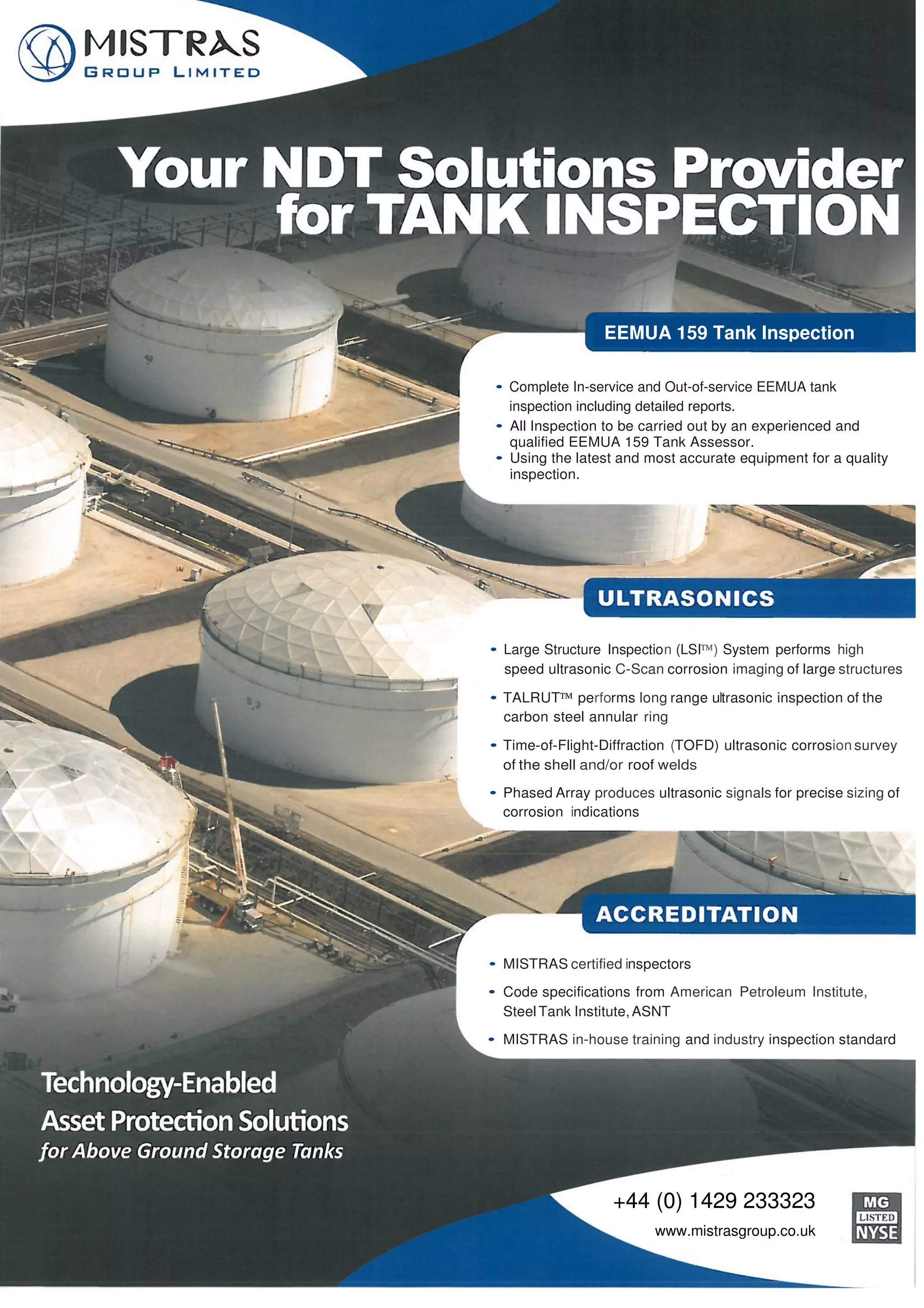

MISTRAS GROUP LTD is an inspection company that offers complete tank inspection services using a variety of techniques including ultrasonic C-Scan corrosion imaging, long range ultrasonic inspection of tank annular rings, phased array ultrasonic testing, and inspections according to EEMUA 159 and API 653 standards. They provide in-service and out-of-service inspections along with risk-based inspection planning and advanced non-destructive testing methods to help owners comply with regulations and ensure tank integrity. Their TOTAL TANK CARE program includes traditional and state-of-the-art tank inspection and assessment techniques.