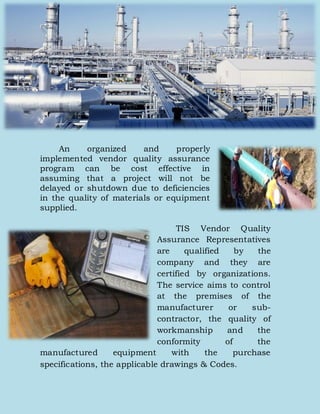

Technocrat Inspection Services is an inspection company that provides quality assurance services to oil, gas, petrochemical, and other heavy industries. They have experienced inspectors with technical backgrounds who perform third party inspections, testing, quality control, and other services. Their goal is to ensure clients' materials and equipment meet requirements and projects are not delayed due to quality issues. They offer a range of inspection services including vendor surveillance, expediting, non-destructive testing, and in-service inspections using risk-based methodology.