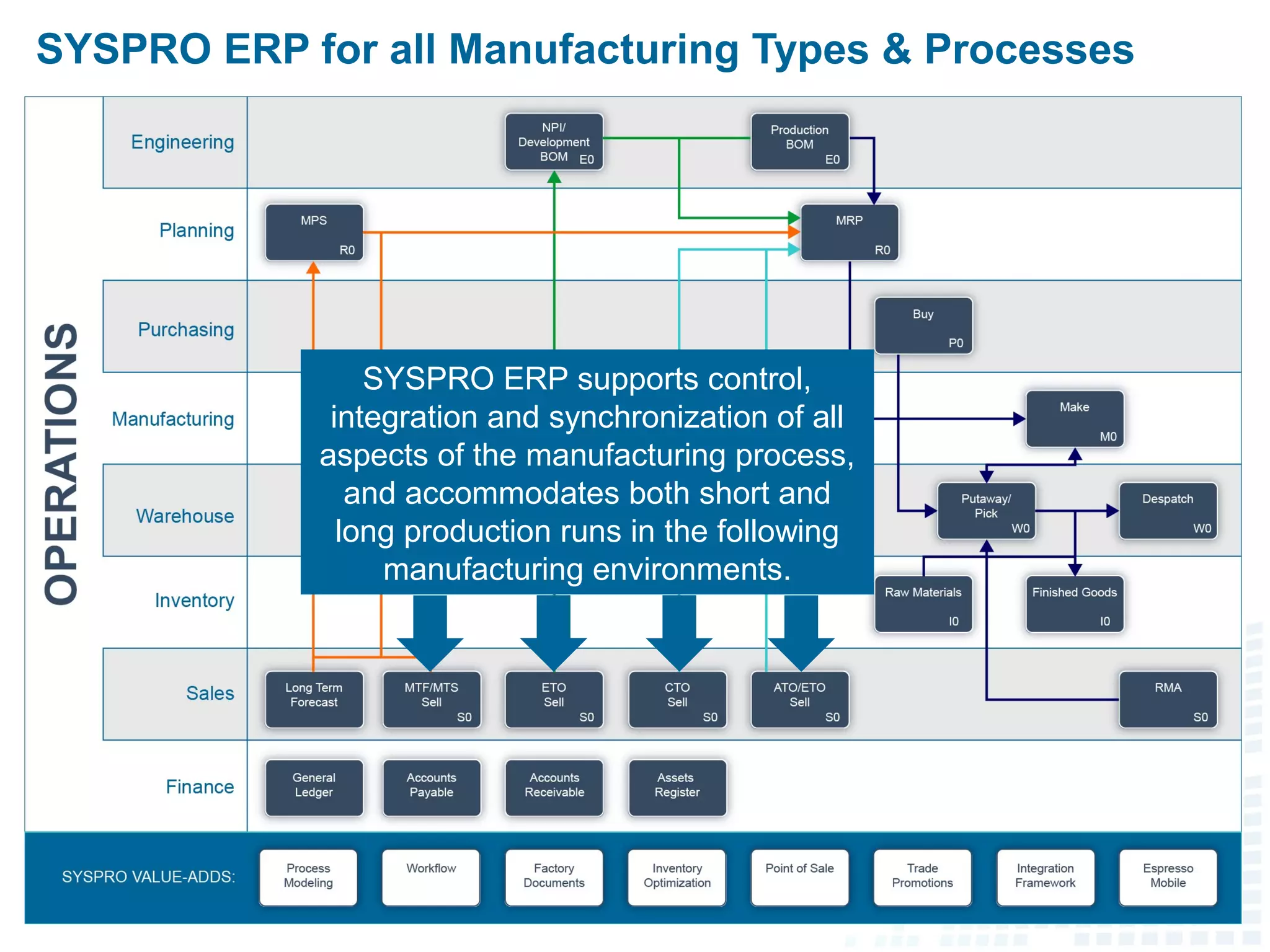

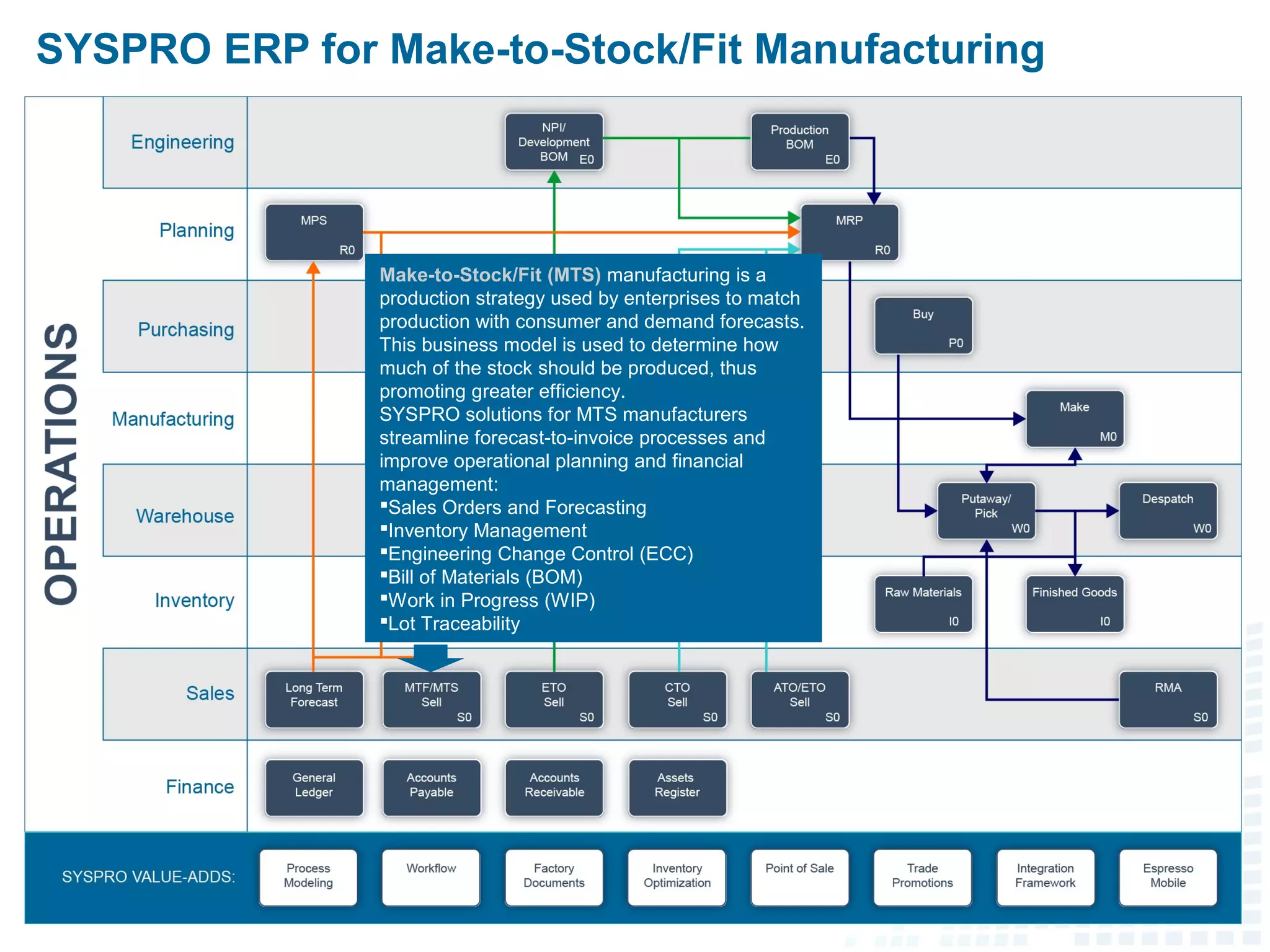

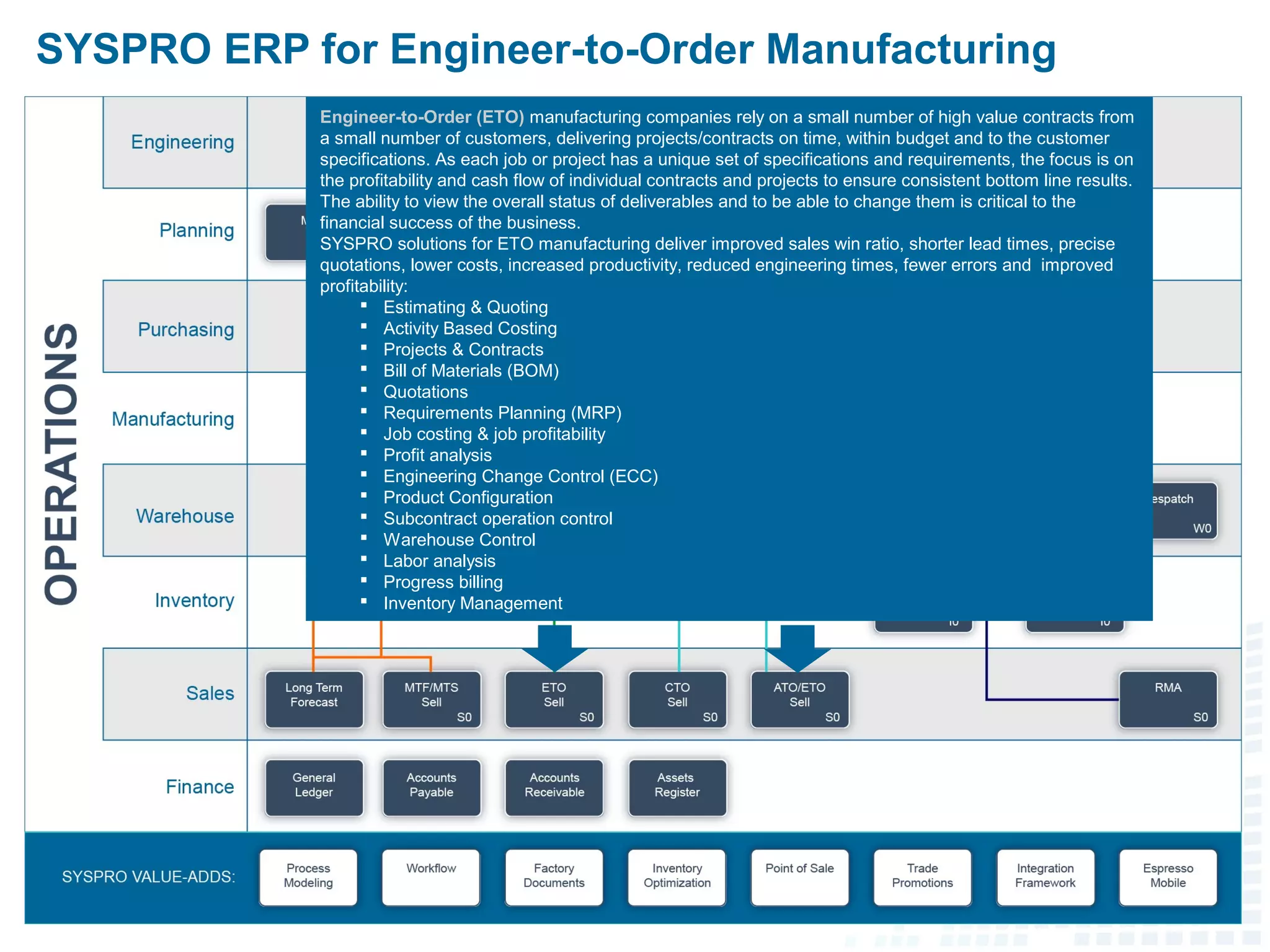

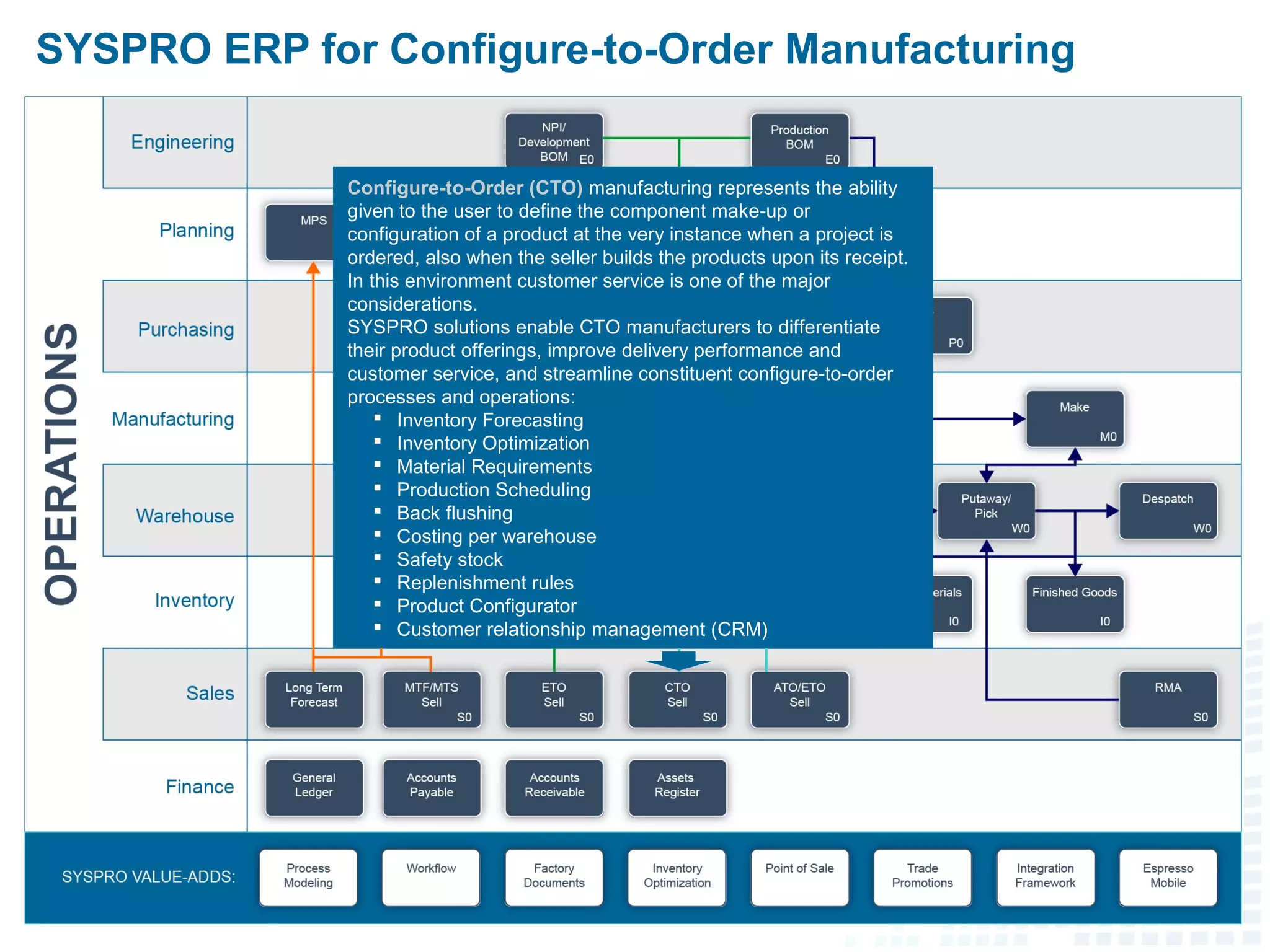

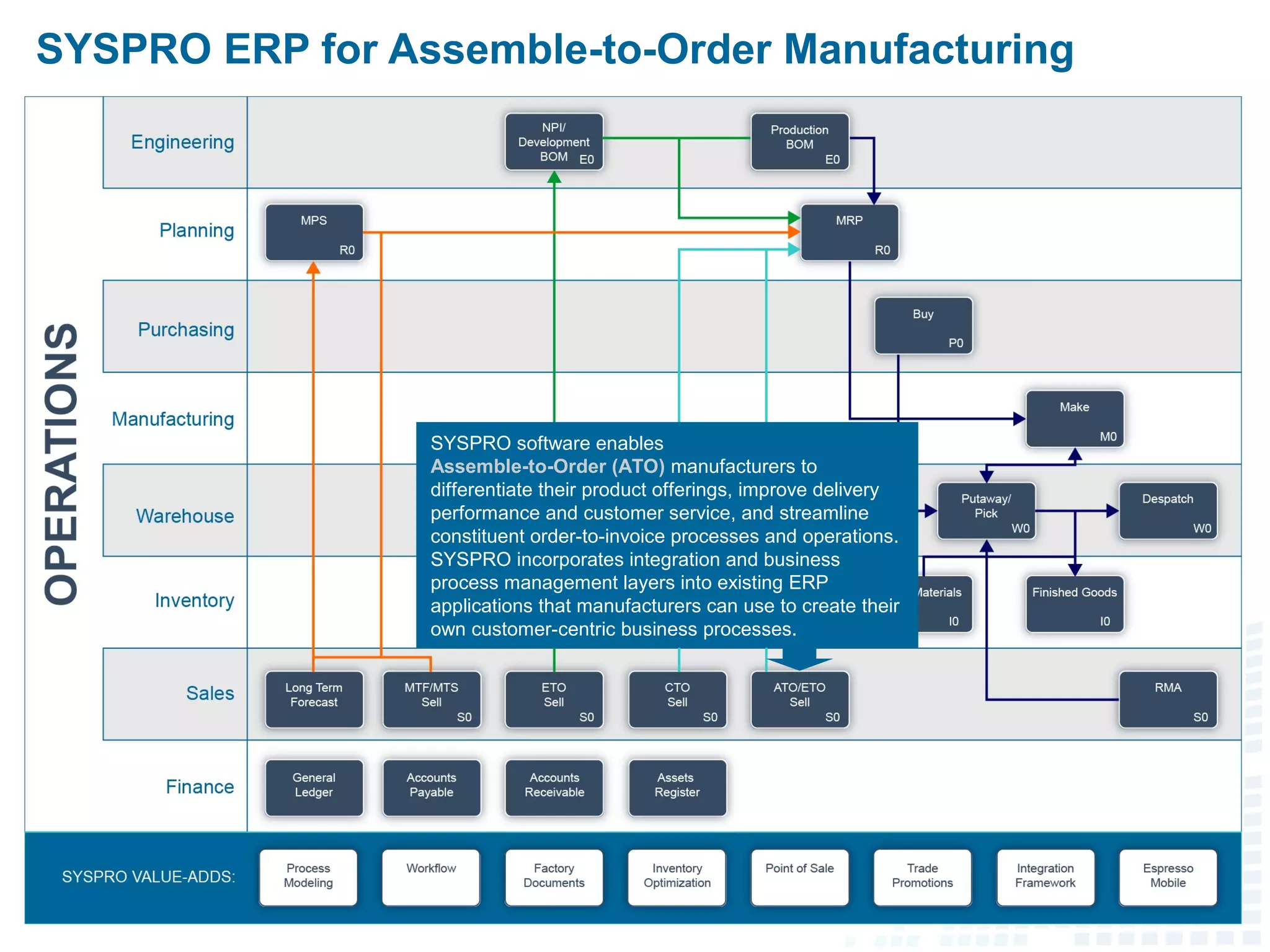

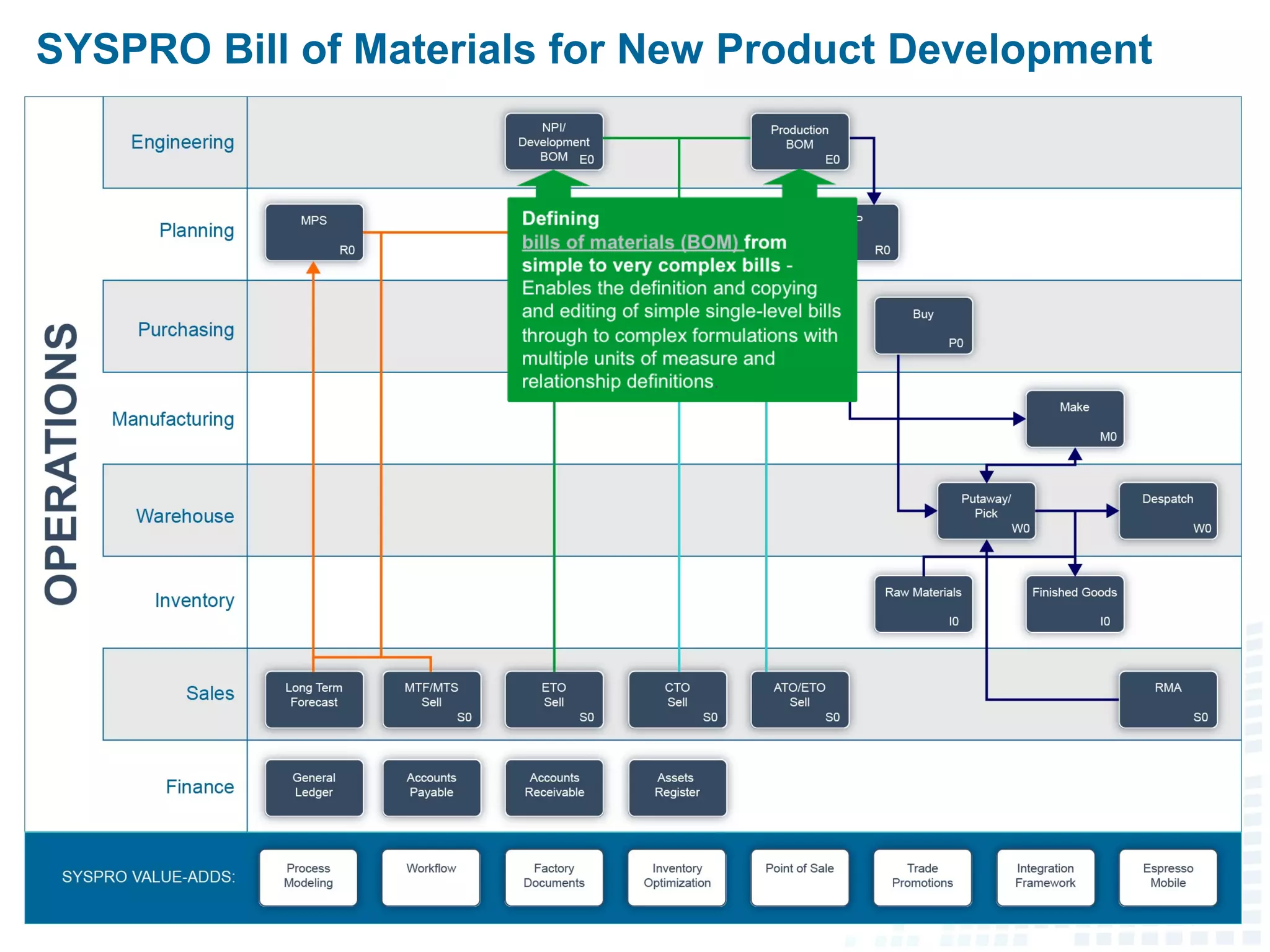

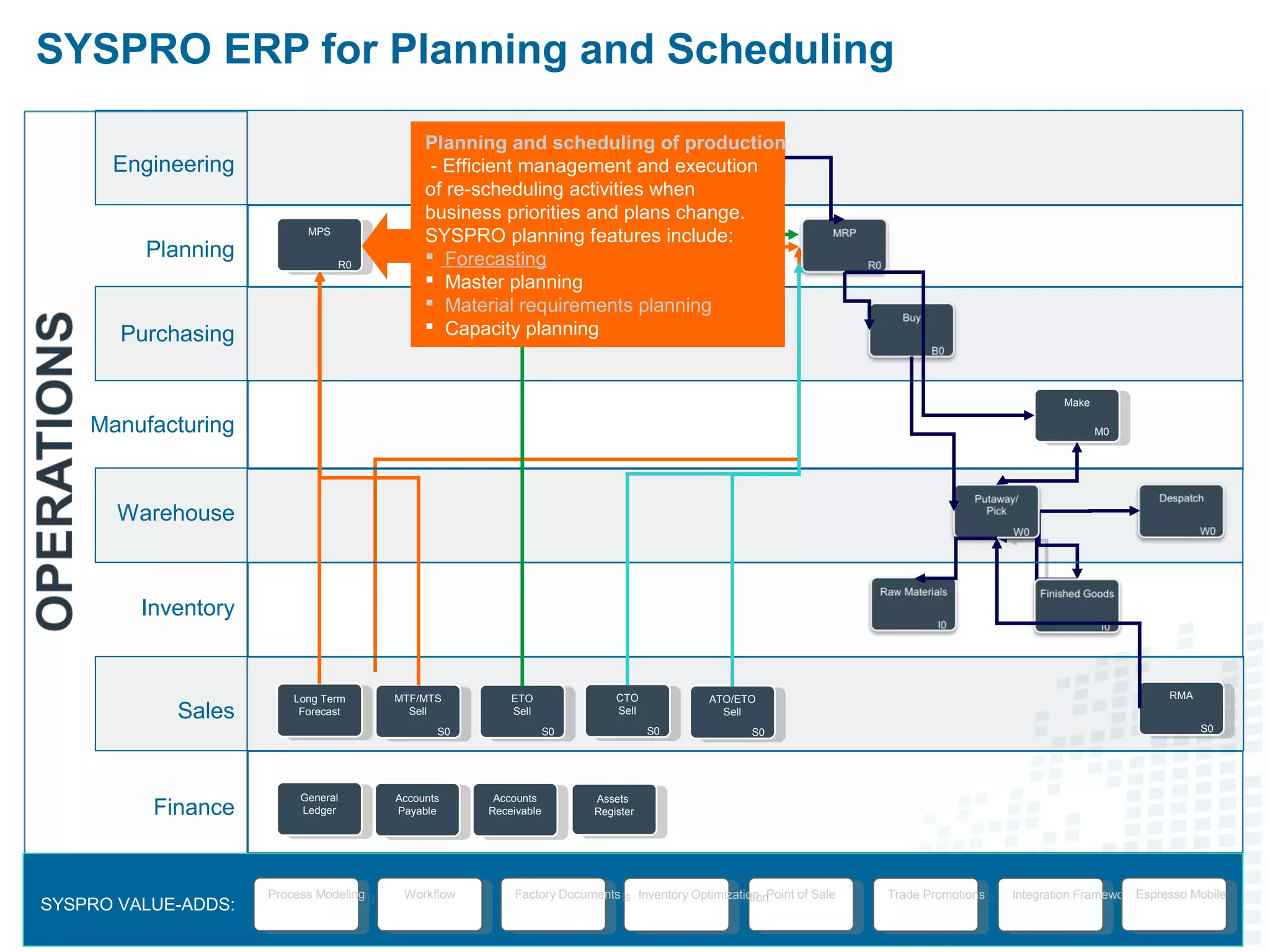

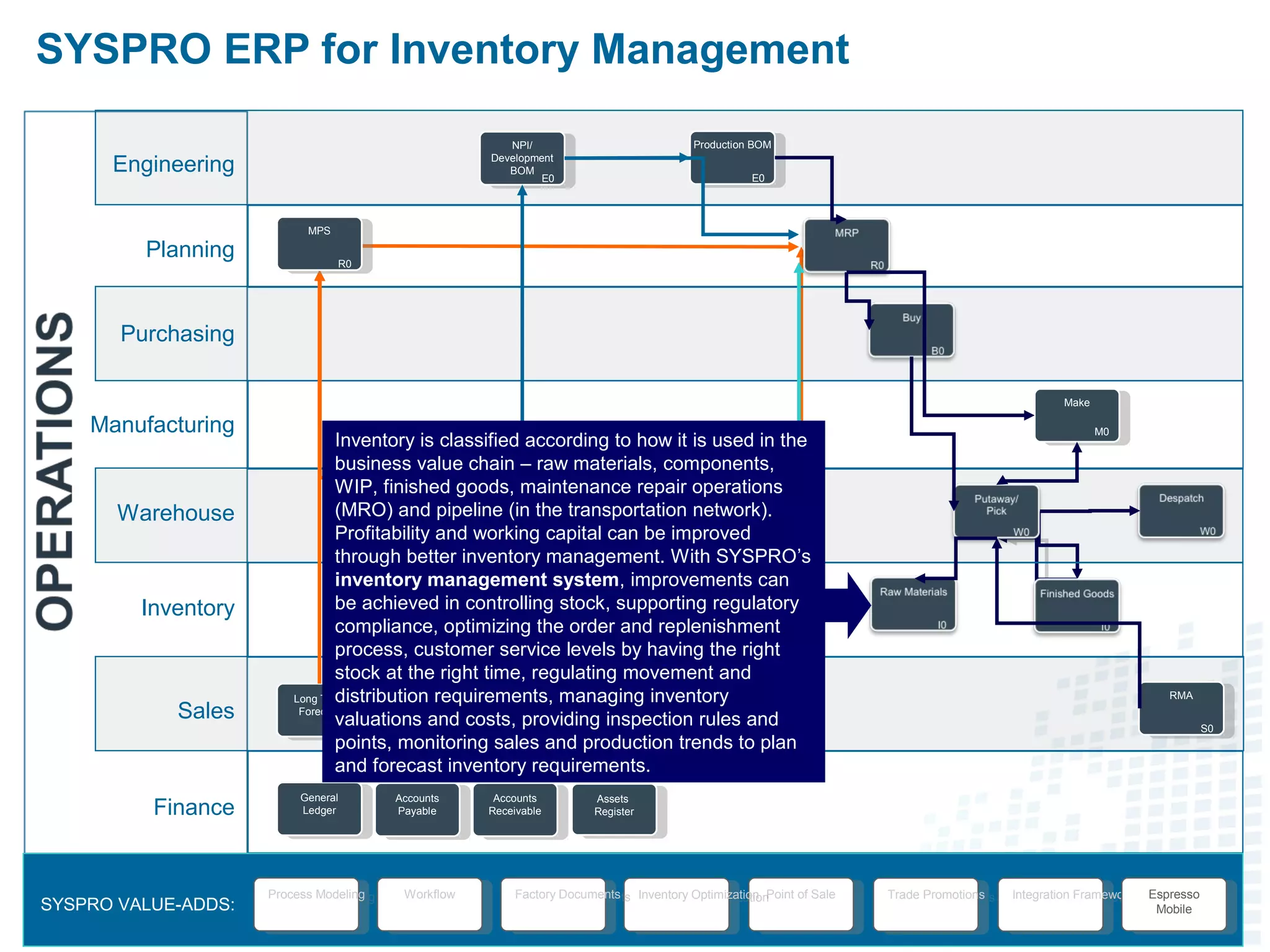

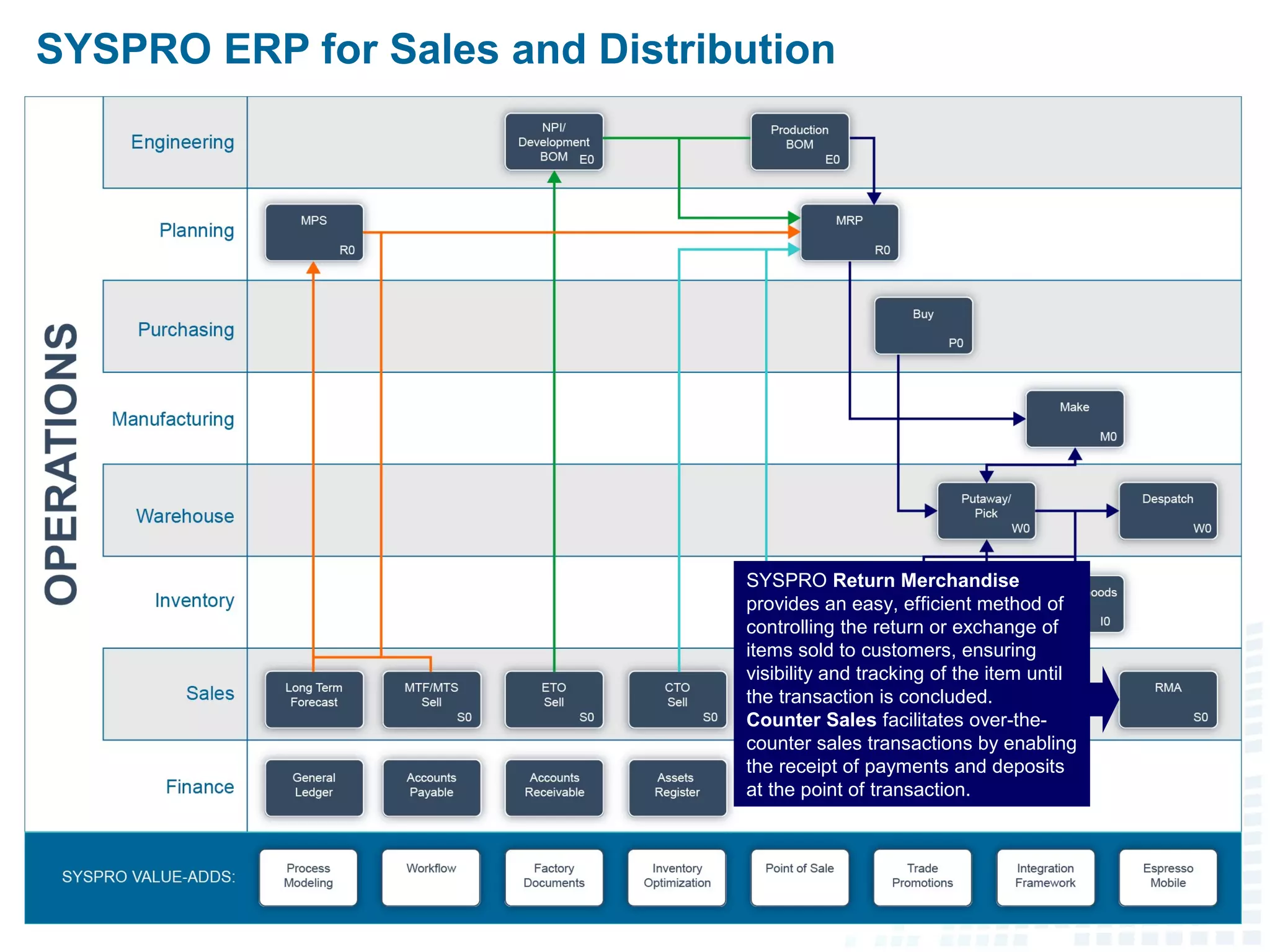

SYSPRO ERP offers comprehensive solutions for various manufacturing types including make-to-stock, engineer-to-order, configure-to-order, and assemble-to-order processes. It enhances efficiency by streamlining operations such as inventory management, production scheduling, and sales forecasting while ensuring accurate cost tracking and improving customer service. The software includes features for project costing, engineering change control, and warehouse management to optimize performance in manufacturing environments.