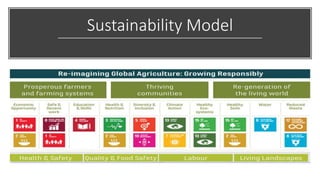

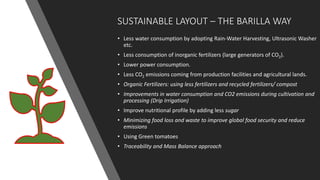

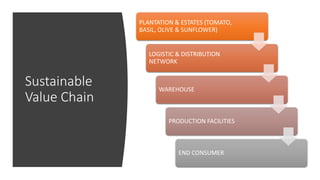

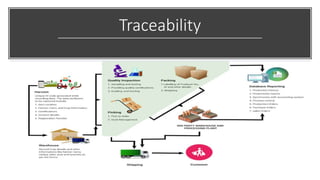

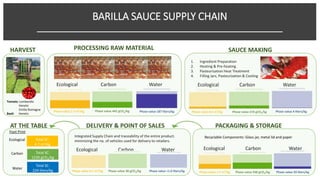

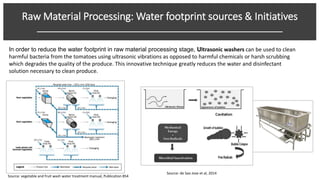

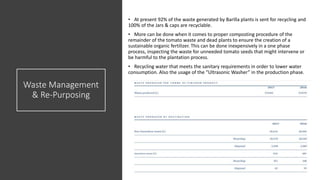

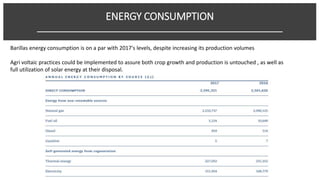

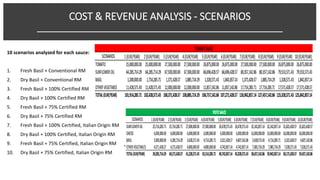

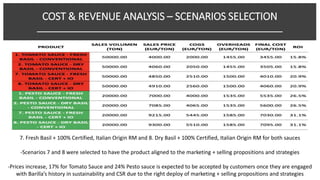

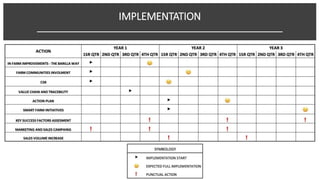

This document summarizes Barilla's sustainability initiatives for its sauce business. It outlines Barilla's vision of providing tasty, nutritious products while promoting healthy lifestyles and sustainability. The company aims to reduce its environmental impact through various measures in its supply chain such as using less water and fertilizers in cultivation, implementing traceability programs, and minimizing food waste. It analyzes the carbon, water and ecological footprints of Barilla's sauce supply chain and identifies opportunities for improvement. The document also discusses Barilla's plans for marketing its sustainability efforts to engage customers and the expected benefits of increased sales volumes.