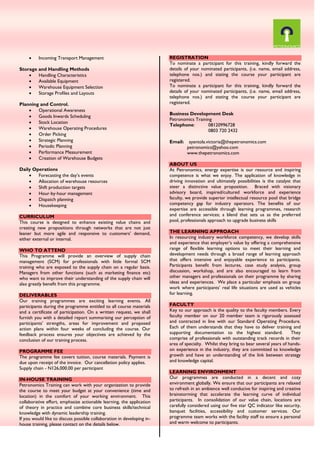

This document provides information about a Supply Chain Management course taking place in Lagos, Nigeria from March 23-25, 2015. The 3-day course will provide participants with an understanding of supply chain operations and key concepts. Participants will gain experience in areas like logistics, materials management, developing integrated supply chains, and measuring performance. The course will be taught through modules covering topics such as supply chain strategy, inventory management, warehousing, and planning. It is designed for professionals with little formal supply chain training.