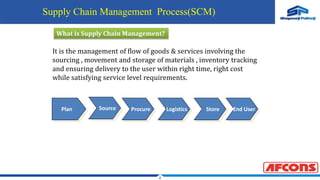

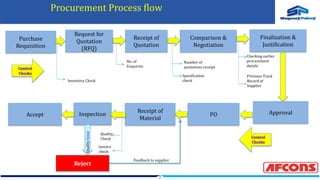

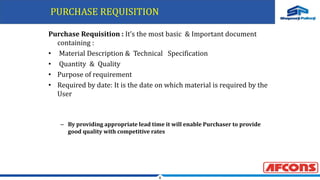

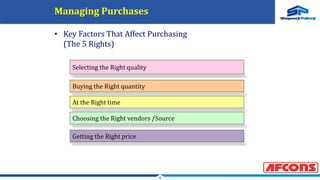

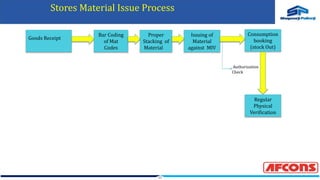

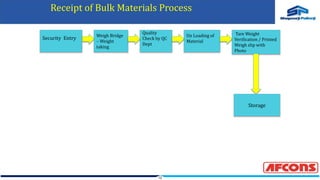

Supply chain management involves planning and managing the flow of goods and services. It includes sourcing, procurement, conversion, and logistics management processes. SCM plays an important role in obtaining materials and services on budget and on time for end users. The key SCM processes are procurement, inventory management, and logistics. Effective SCM requires managing purchase requisitions, vendor selection, inventory levels, material receiving, inspection, storage and issue processes.

![15

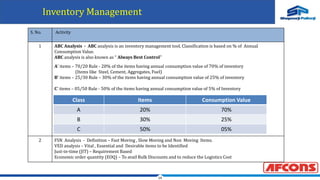

ABC Analysis

200000

500

20

199500

500

19

199000

500

18

198500

500

17

198000

500

16

197500

500

15

197000

500

14

196500

500

13

196000

1500

12

194500

1500

11

193000

1750

10

191250

2750

9

188500

4000

8

184500

4500

7

180000

5000

6

175000

7500

5

167500

7500

4

160000

20000

3

140000

50000

2

90000

90000

1

CUMMULATIVE

CUMMULATIVE

COST

COST [Rs.]

ANNUAL COST

ANNUAL COST

[Rs.]

ITEM

ITEM COST %

COST %

ITEM %

ITEM %

70 %

70 %

20 %

20 %

10 %

10 %

10 %

10 %

20 %

20 %

70 %

70 %

ABC

A

N

A

L

Y

S

I

S

WORK

SHEET](https://image.slidesharecdn.com/scmppt17978-220216065201/85/SUPPLY-CHAIN-MANAGEMENT-15-320.jpg)