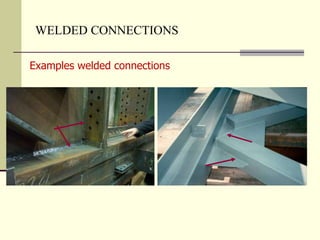

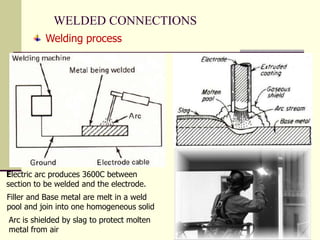

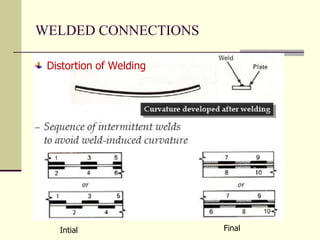

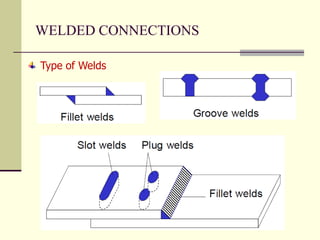

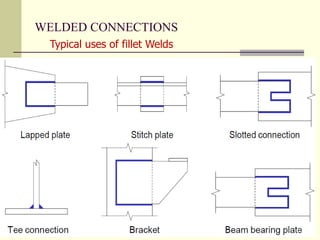

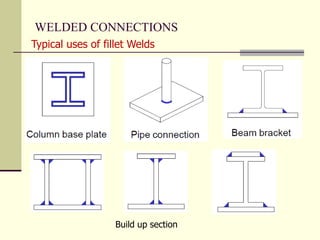

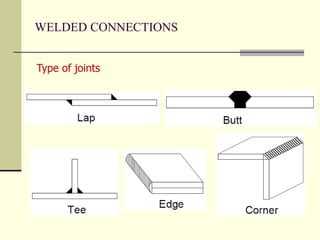

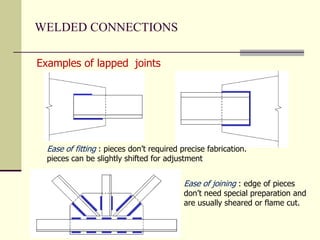

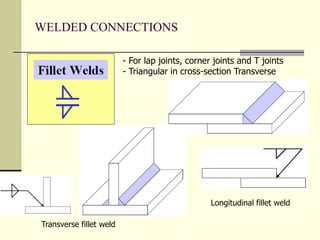

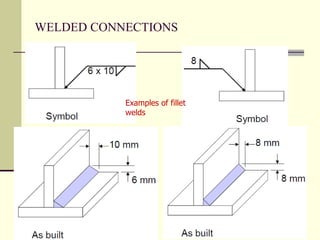

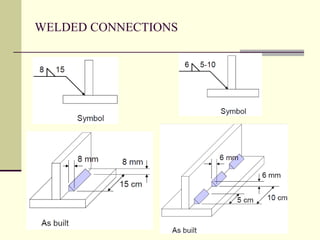

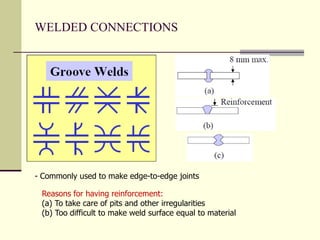

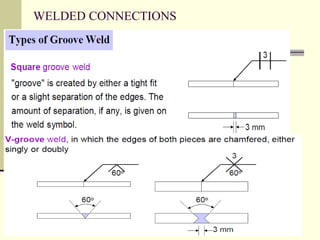

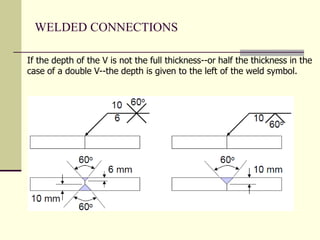

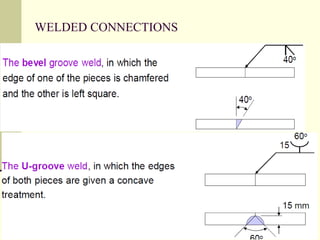

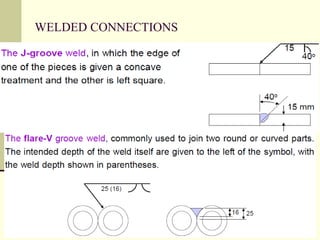

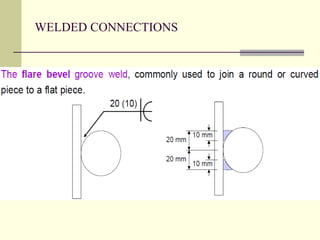

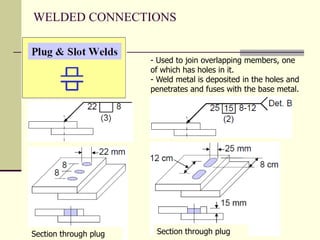

This document focuses on welded connections in structural steel design, covering the advantages, processes, inspections, and types of welds. It highlights how welding has replaced riveting in construction due to its cost-effectiveness and ability to create strong joints. Additionally, it addresses the disadvantages of welding, such as brittleness and challenges in quality control.