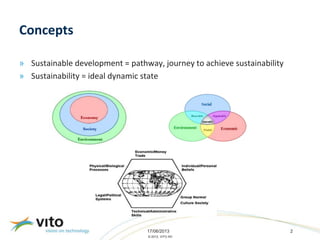

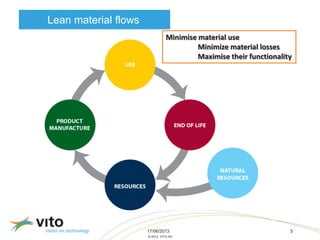

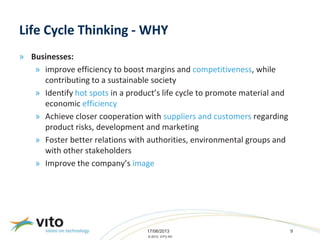

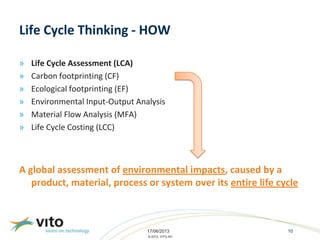

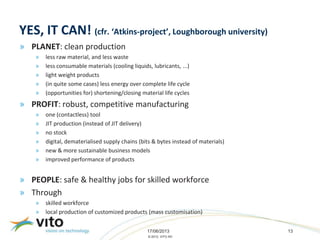

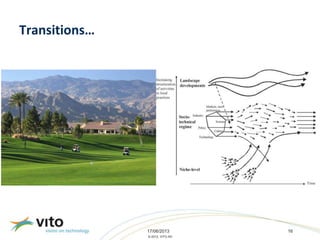

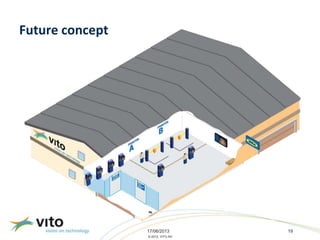

The document discusses sustainable materials management (SMM) and the principles of sustainable development, emphasizing the importance of life cycle thinking for improving efficiency and reducing environmental impacts in various industries. It explores how additive manufacturing can contribute to SMM by promoting local production, reducing material waste, and enabling mass customization. It also touches on the concept of Jevons Paradox, where increased efficiency in resource use can lead to higher consumption rates.