This document provides information about steam traps and condensate drainage. It includes:

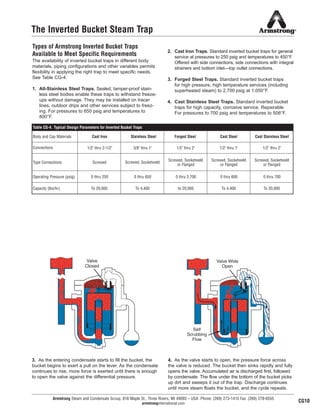

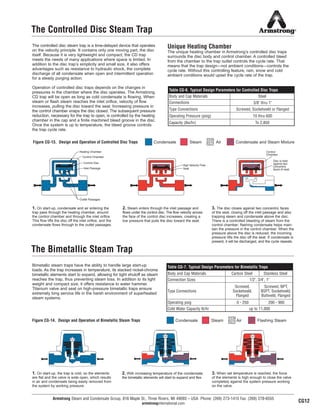

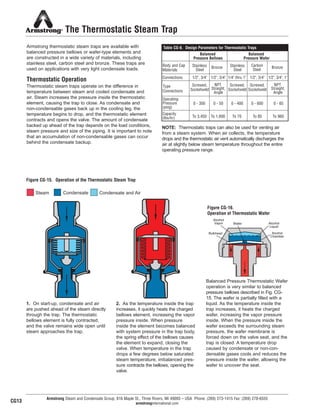

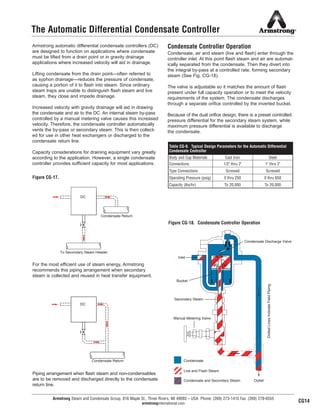

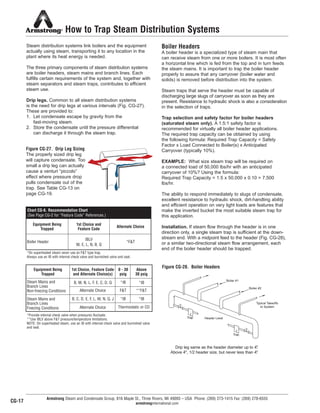

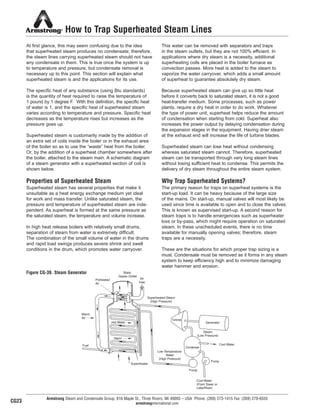

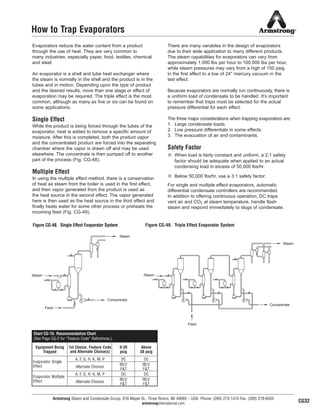

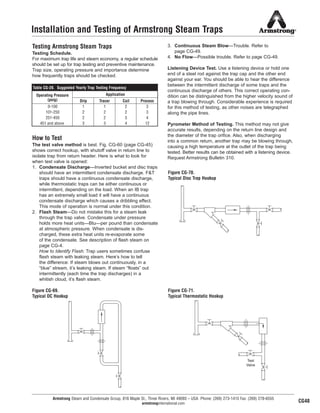

- Diagrams and descriptions of common steam trap types including inverted bucket, float and thermostatic, controlled disc, and thermostatic traps.

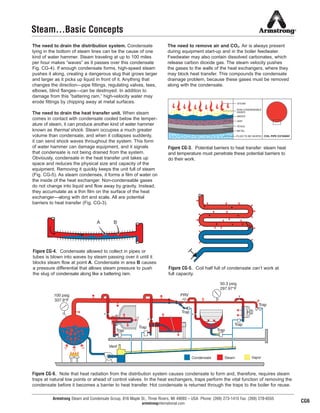

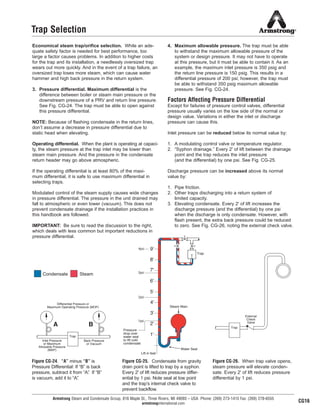

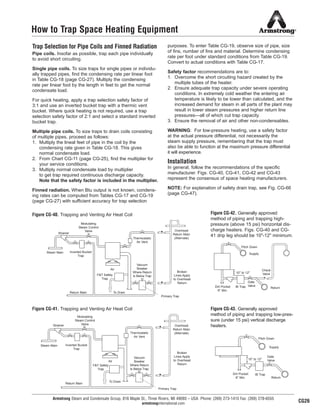

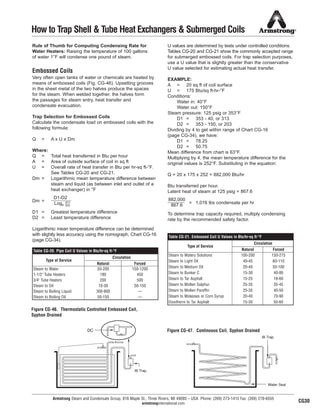

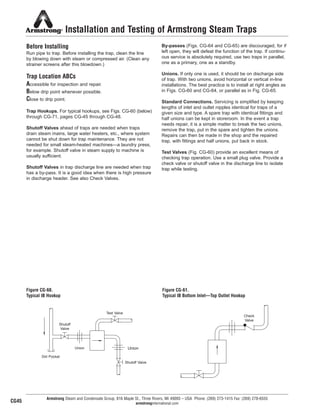

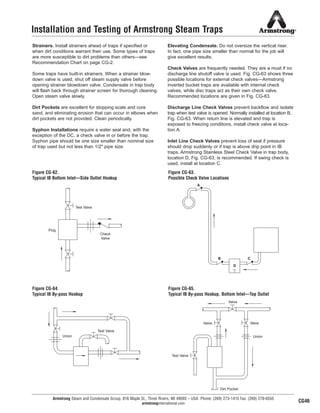

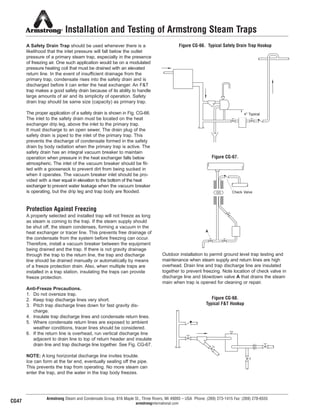

- Guidelines for selecting and installing steam traps for various applications such as steam distribution systems, process equipment, heat exchangers, and more.

- Steam tables that define steam properties and relationships between pressure, temperature, heat of vaporization, and specific volume.

- Instructions for using recommendation charts to determine the best steam trap type for a given application based on key characteristics.