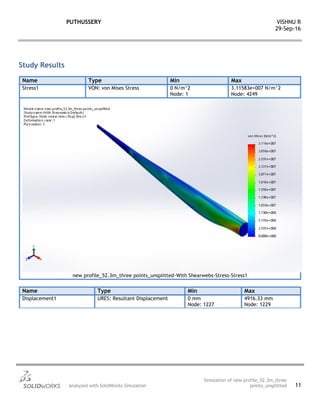

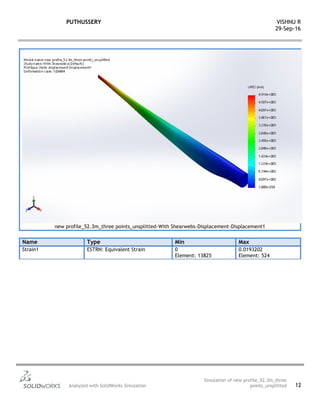

The document summarizes the results of a static simulation analysis conducted on a new wind turbine profile model with shear webs. The maximum von Mises stress was found to be 3.11583e+007 N/m^2 and the maximum resultant displacement was 4916.33 mm. Introducing shear webs to the model reduced the resultant displacement by 10% compared to a model without shear webs, demonstrating their reinforcing effect against flexural loads. Further analytical validation of the study results is required.

![PUTHUSSERY VISHNU R

29-Sep-16

Analyzed with SolidWorks Simulation

Simulation of new profile_52.3m_three

points_unsplitted 3

Surface-Extrude1[1]

Total number of Plies: 2

Symmetric: No

Ply

Thicknes

s(mm)

Angle(de

g)

Area(m

^2)

Volume

(m^3)

Density(

kg/m^3)

Mass(

kg)

Weight

(N)

1 10 0 105.006 1.05006 1100

1155.

07

11319.

7

2 10 30 105.006 1.05006 1100

1155.

07

11319.

7

Document Name: F:Students projectRonynew profile_52.3m_three

points_unsplitted.SLDPRT

Date Modified: Sep 29 17:37:03 2016

Surface-Extrude1[2]

Total number of Plies: 2

Symmetric: No

Ply

Thicknes

s(mm)

Angle(de

g)

Area(m

^2)

Volume

(m^3)

Density(

kg/m^3)

Mass(

kg)

Weight

(N)

1 10 0 93.3382

0.93338

2

1100

1026.

72

10061.

9

2 10 30 93.3382

0.93338

2

1100

1026.

72

10061.

9

Document Name: F:Students projectRonynew profile_52.3m_three

points_unsplitted.SLDPRT

Date Modified: Sep 29 17:37:03 2016

Split Line1

Total number of Plies: 5

Symmetric: No

Ply

Thicknes

s(mm)

Angle(de

g)

Area(m

^2)

Volume

(m^3)

Density(

kg/m^3)

Mass(

kg)

Weight

(N)

1 10 0 482.229 4.82229 1000

4822.

29

47258.

5

2 10 60 482.229 4.82229 1000

4822.

29

47258.

5

3 10 30 482.229 4.82229 1000

4822.

29

47258.

5

4 10 60 482.229 4.82229 1000

4822.

29

47258.

5

5 10 0 482.229 4.82229 1000

4822.

29

47258.

5

Document Name: F:Students projectRonynew profile_52.3m_three

points_unsplitted.SLDPRT

Date Modified: Sep 29 17:37:03 2016](https://image.slidesharecdn.com/52-160930233325/85/STATIC-STRUCTURAL-ANALYSIS-ON-HAWT-BLADE-3-320.jpg)

![PUTHUSSERY VISHNU R

29-Sep-16

Analyzed with SolidWorks Simulation

Simulation of new profile_52.3m_three

points_unsplitted 5

Units

Unit system: SI (MKS)

Length/Displacement mm

Temperature Kelvin

Angular velocity Rad/sec

Pressure/Stress N/m^2

Material Properties

Model Reference Properties Components

Name: Epoxy, Unfilled

Model type: Linear Elastic Isotropic

Default failure

criterion:

Unknown

Tensile strength: 2.8e+007 N/m^2

Compressive

strength:

1.04e+008 N/m^2

Elastic modulus: 2.415e+009 N/m^2

Poisson's ratio: 0.35

Mass density: 1100 kg/m^3

SurfaceBody 1(Surface-

Extrude1[1])(new

profile_52.3m_three

points_unsplitted),

SurfaceBody 2(Surface-

Extrude1[2])(new

profile_52.3m_three

points_unsplitted),

SurfaceBody 3(Split

Line1)(new

profile_52.3m_three

points_unsplitted),

SurfaceBody 4(Surface-

Fill1)(new

profile_52.3m_three

points_unsplitted)

Curve Data:N/A](https://image.slidesharecdn.com/52-160930233325/85/STATIC-STRUCTURAL-ANALYSIS-ON-HAWT-BLADE-5-320.jpg)