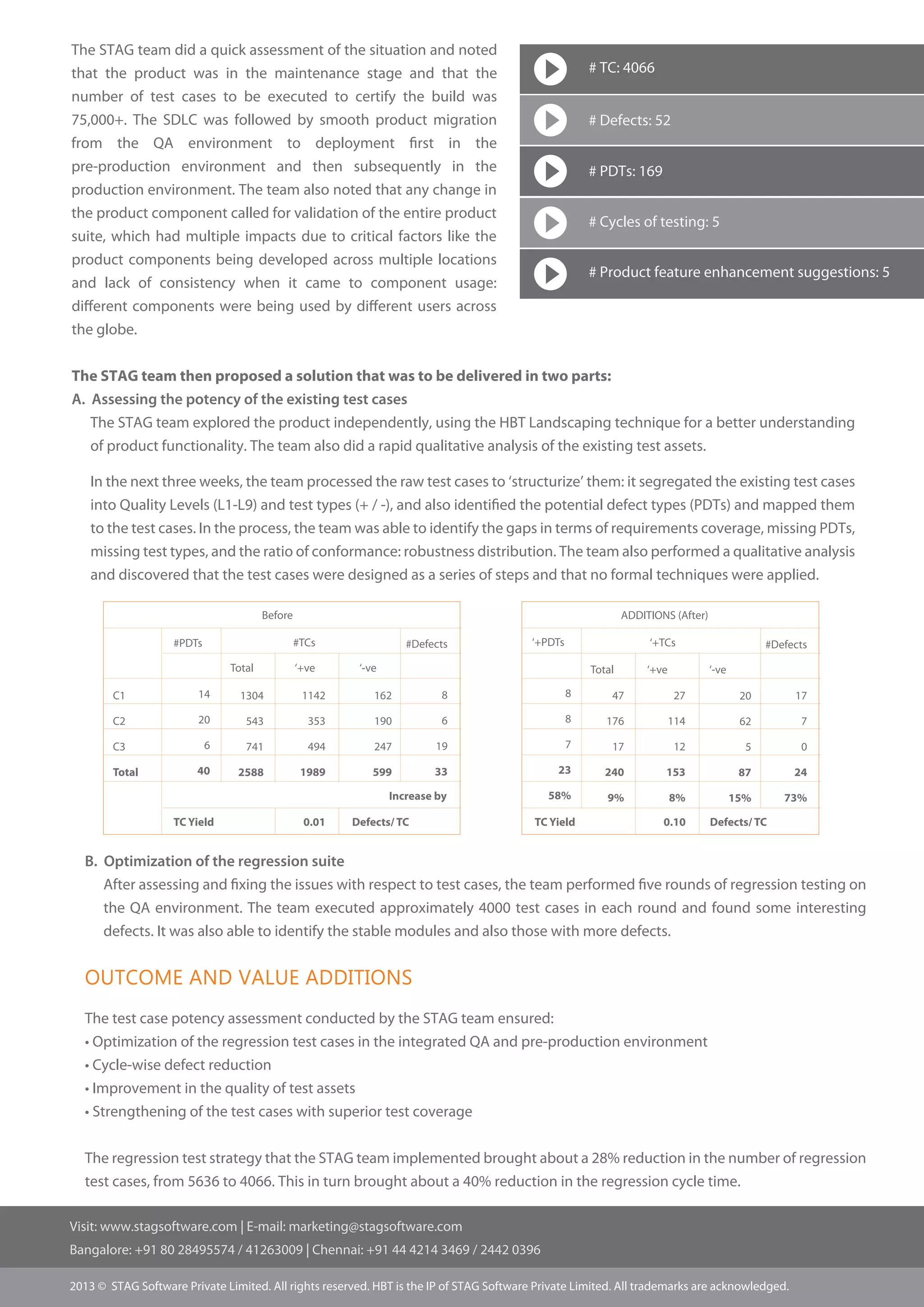

The document outlines a case study on optimizing regression testing for a B2B e-commerce platform, addressing concerns about excessive testing versus development efforts. An independent QA team assessed existing test cases, resulting in a 28% reduction in regression test cases and a 40% decrease in regression cycle time. The assessment also highlighted gaps in test coverage and quality, helping improve the overall testing process for the client.