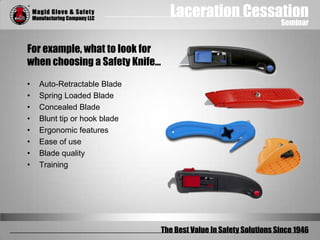

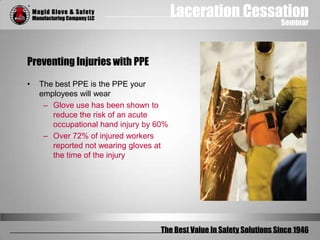

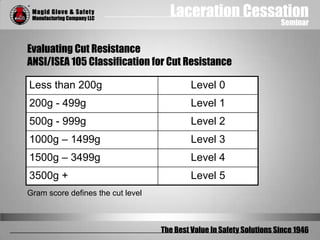

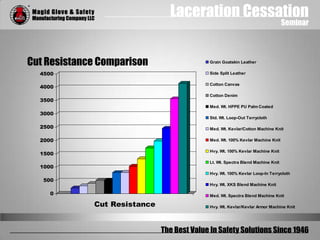

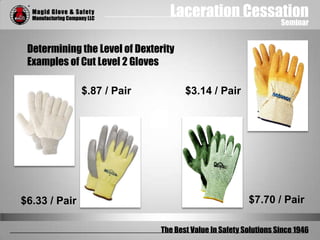

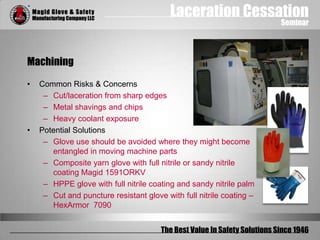

The document outlines the importance of preventing laceration injuries in the workplace, emphasizing the various costs associated with such injuries and the effectiveness of personal protective equipment (PPE). It discusses statistical data on injury frequency, potential financial impacts, and best practices for risk assessment, process improvements, and glove selection to enhance safety. The seminar aims to equip attendees with knowledge on preventing injuries, evaluating solutions, and promoting safe practices within industrial settings.