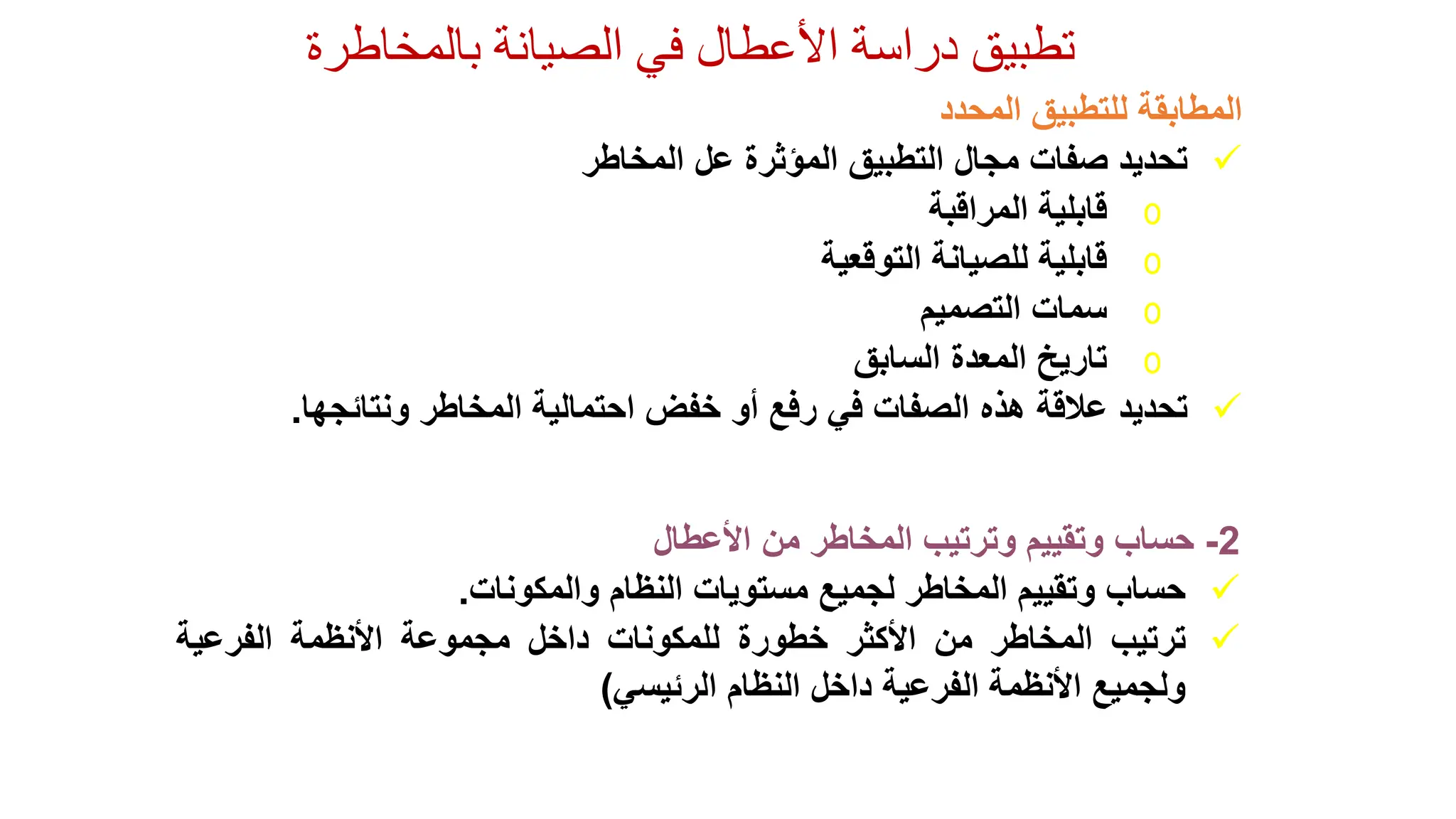

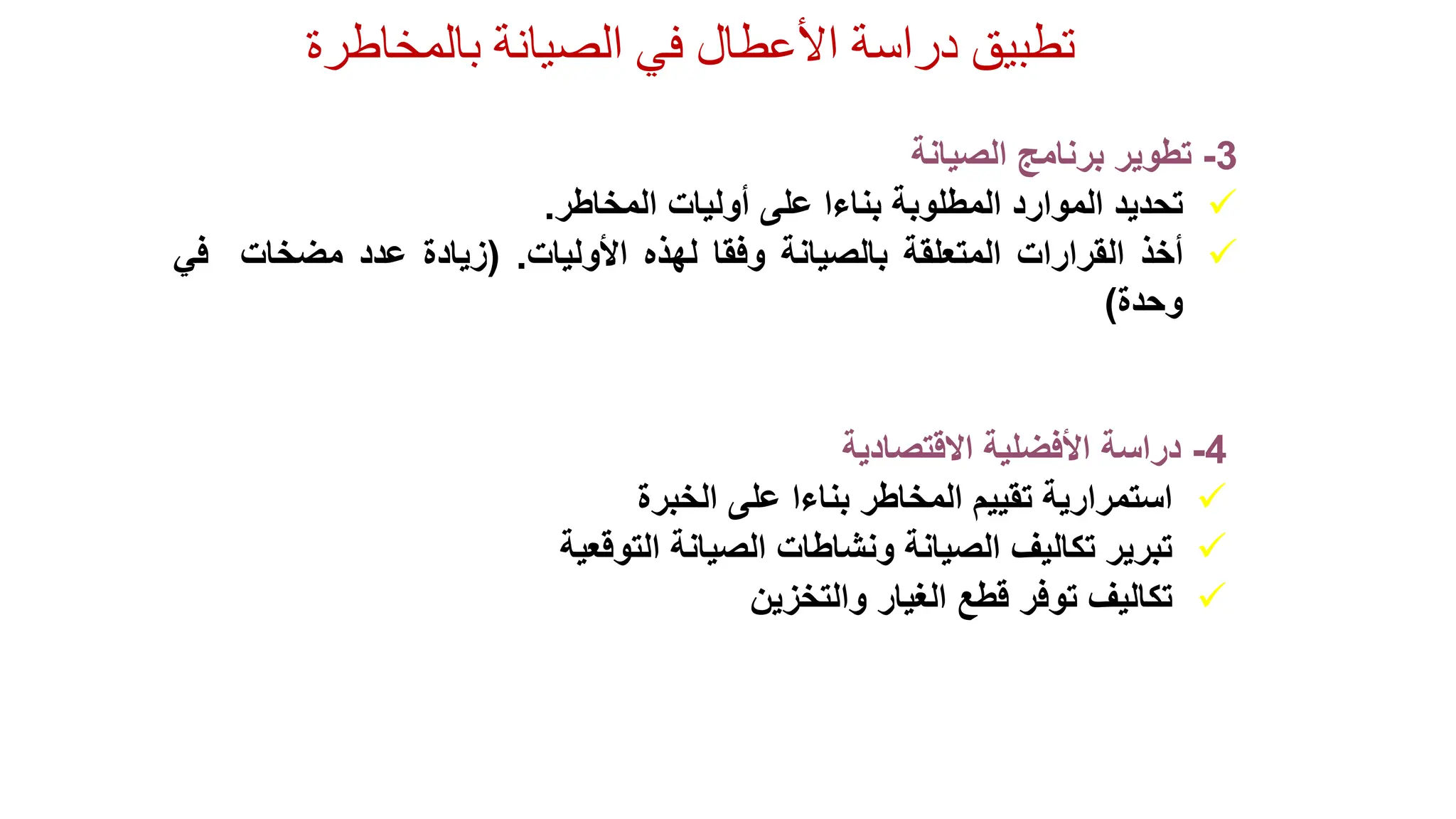

عينة من المحتوى : تحليل معدلات الاحتمالية

إيجاد أنماط الفشل: حساب احتمالات الفشل والموثوقية ، دراسة احتمالات العطل

من البيانات التاريخية والخبرات المكتسبة عن العطل

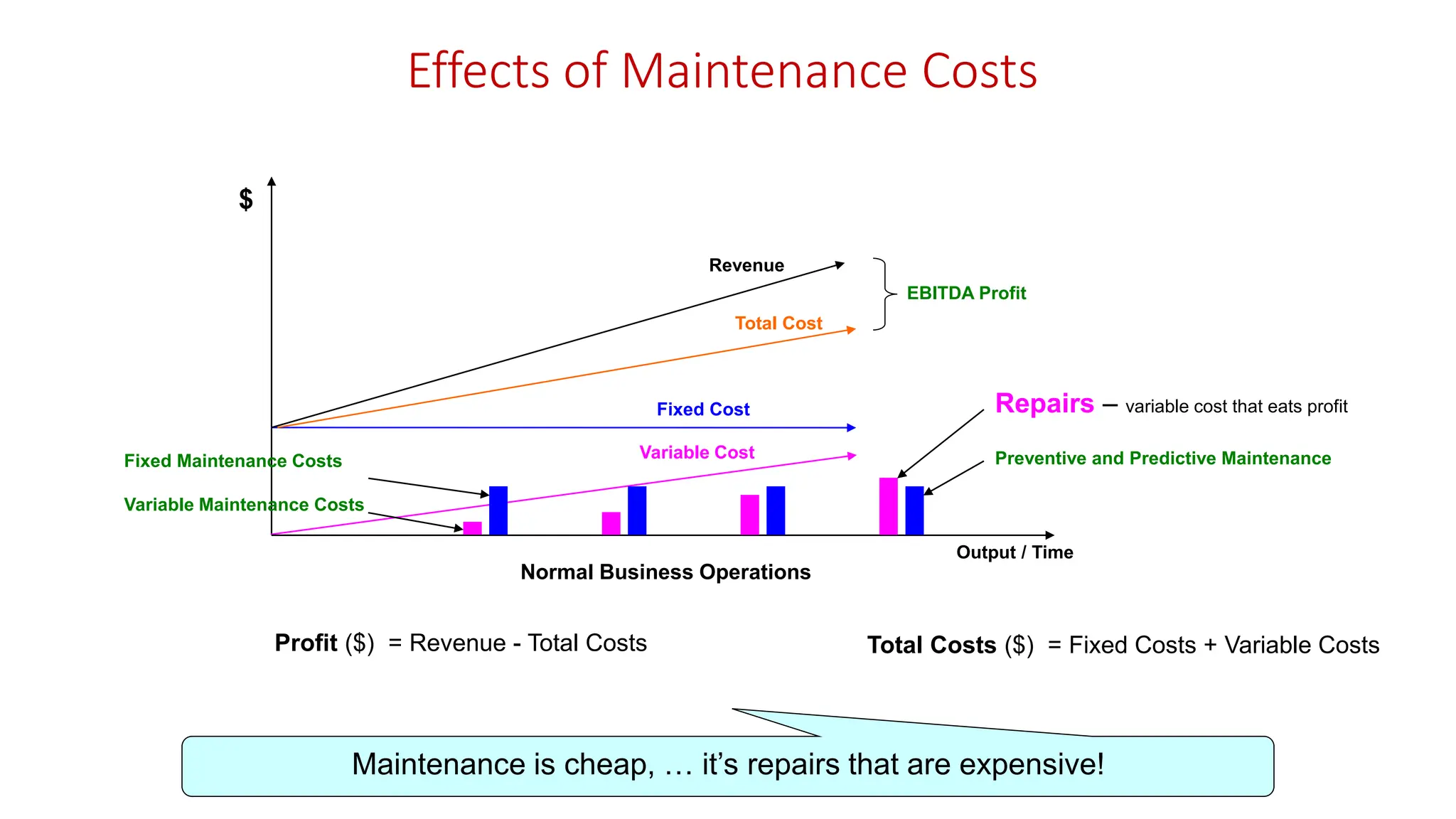

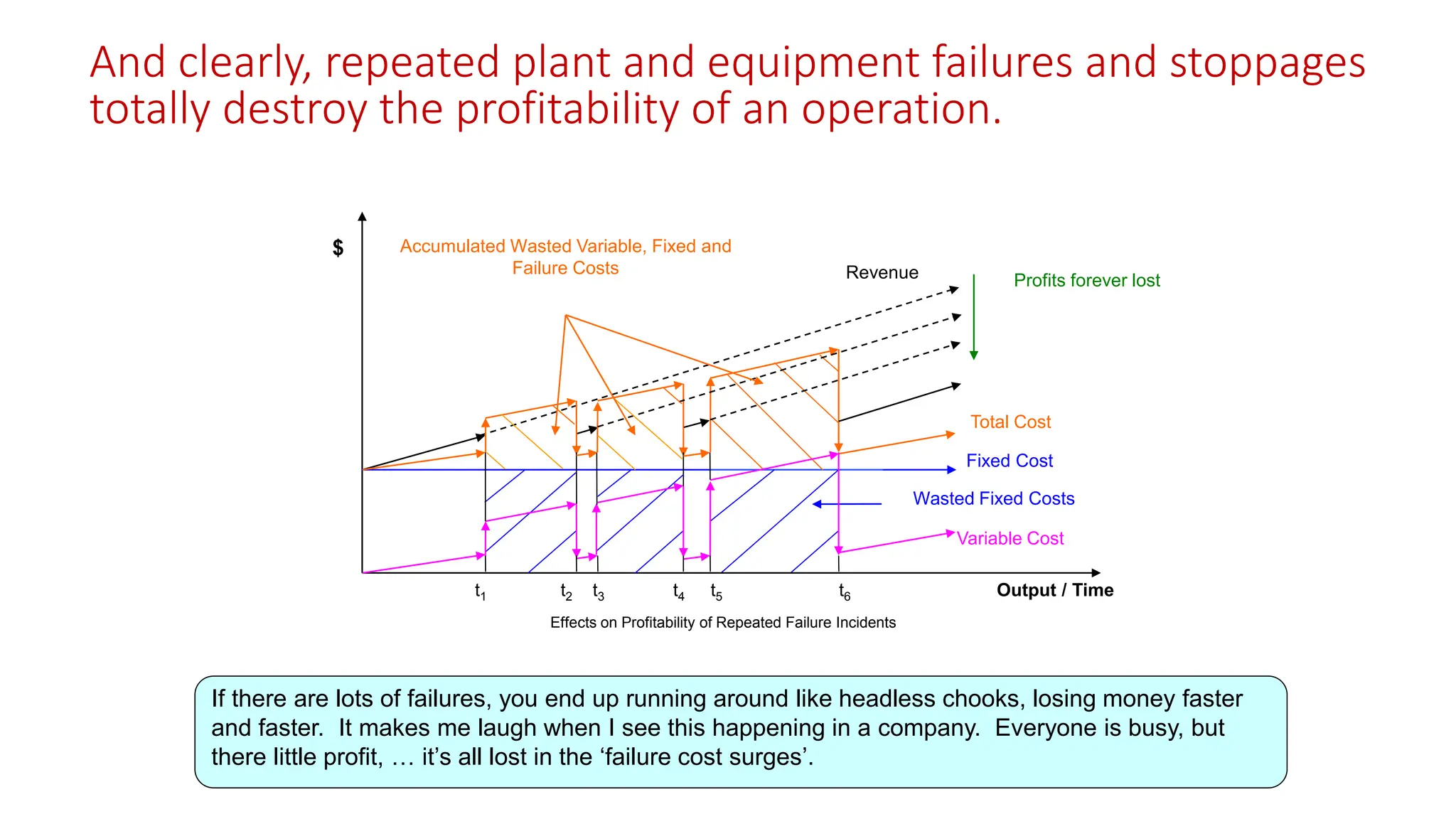

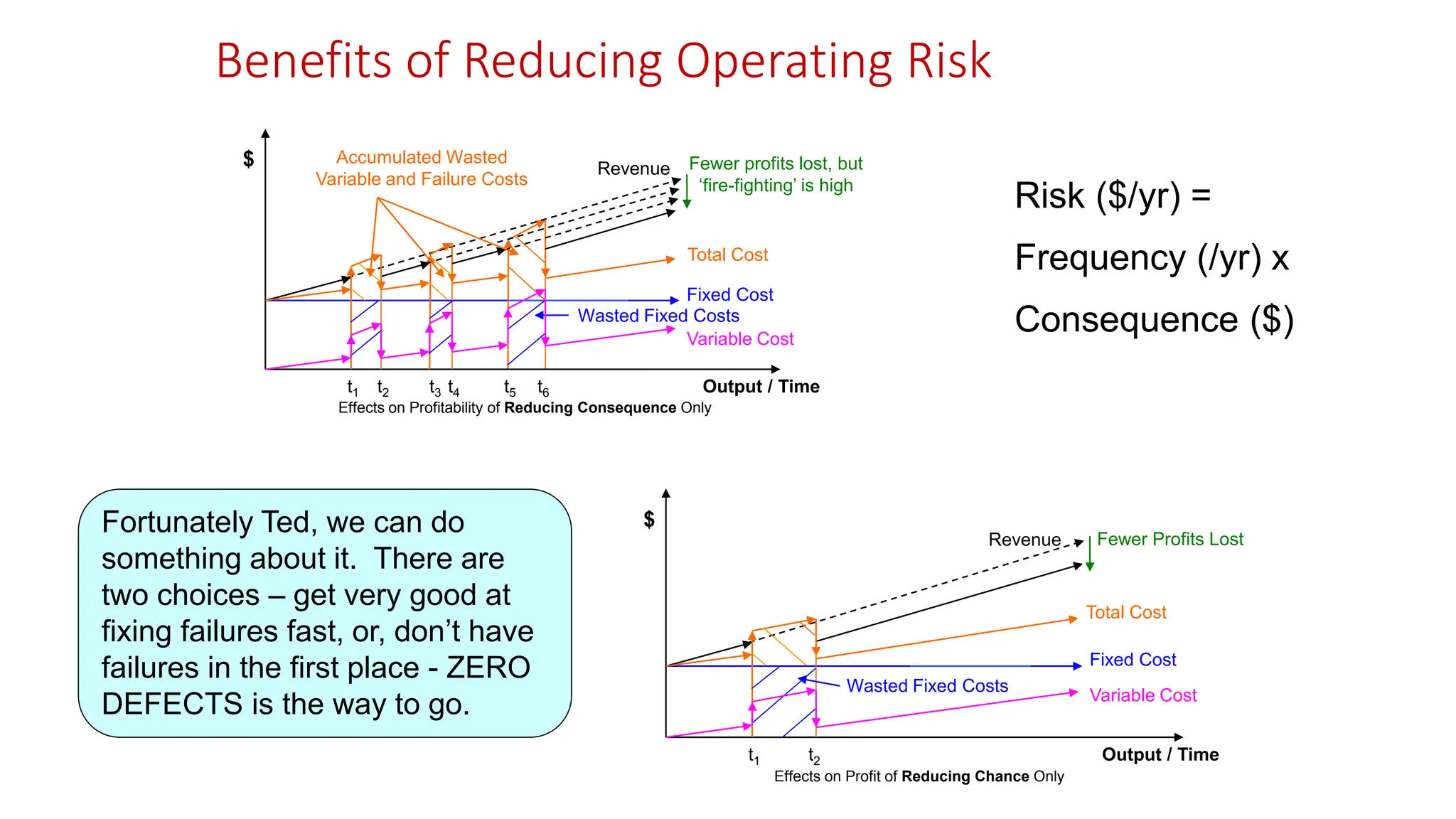

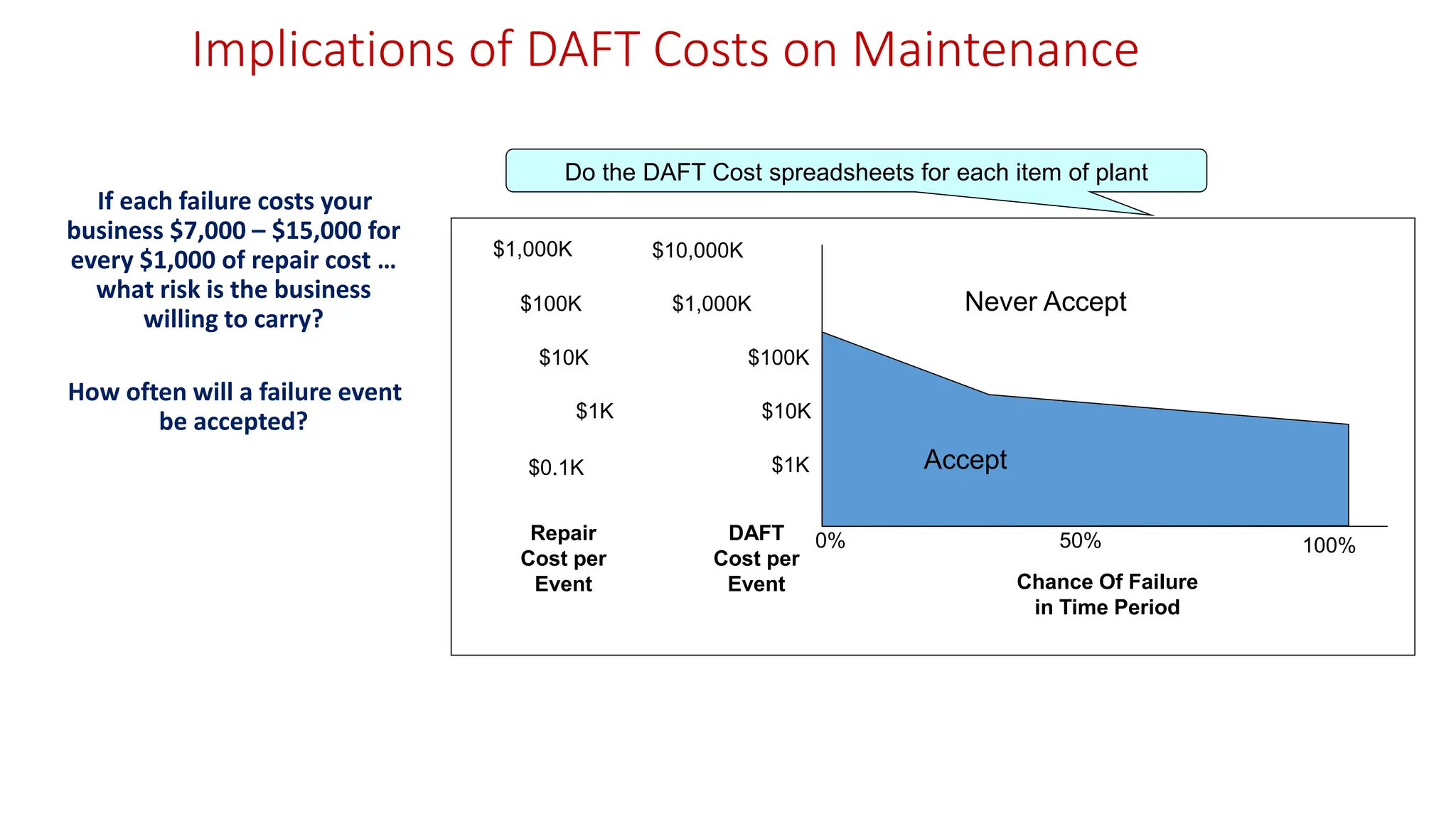

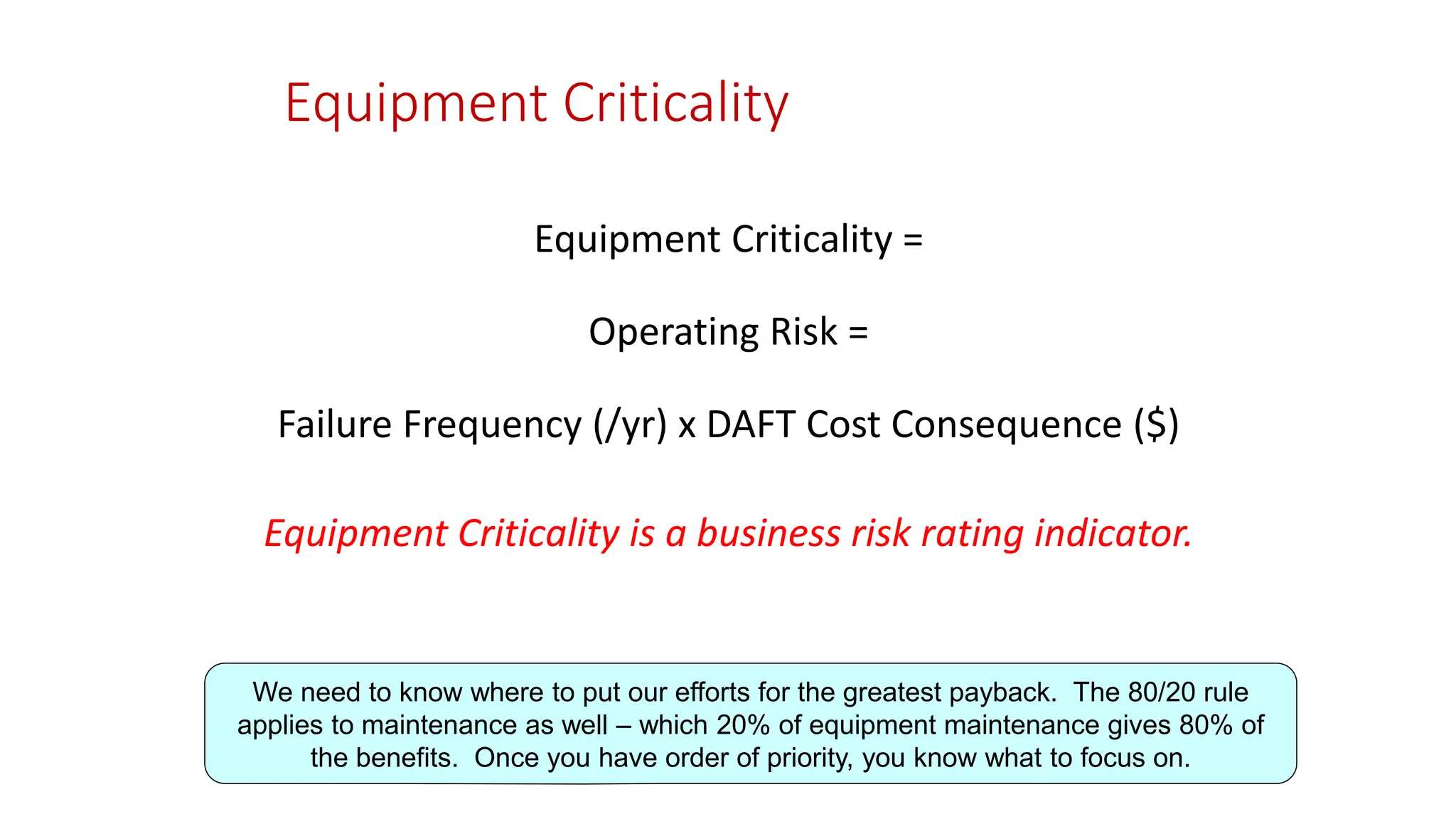

تحليل التكلفة المترتبة على الفشل

تكلفة الإصلاح ، تكلفة صيانة المعدة وتكاليف الهلاك والإحلال

تكلفة الفقد، تكلفة توقف المنظومة هن العمل

تكلفة الفرصة المفقودة ، تكلفة عدم اكتمال الصيانة

![MEAN TIME TO FAILURE [MMTF]

Where f(t) is the failure probability density function](https://image.slidesharecdn.com/random-251120173613-daf465a2/75/slide-83-2048.jpg)

![MEAN TIME TO REPAIR [MTTR]](https://image.slidesharecdn.com/random-251120173613-daf465a2/75/slide-84-2048.jpg)

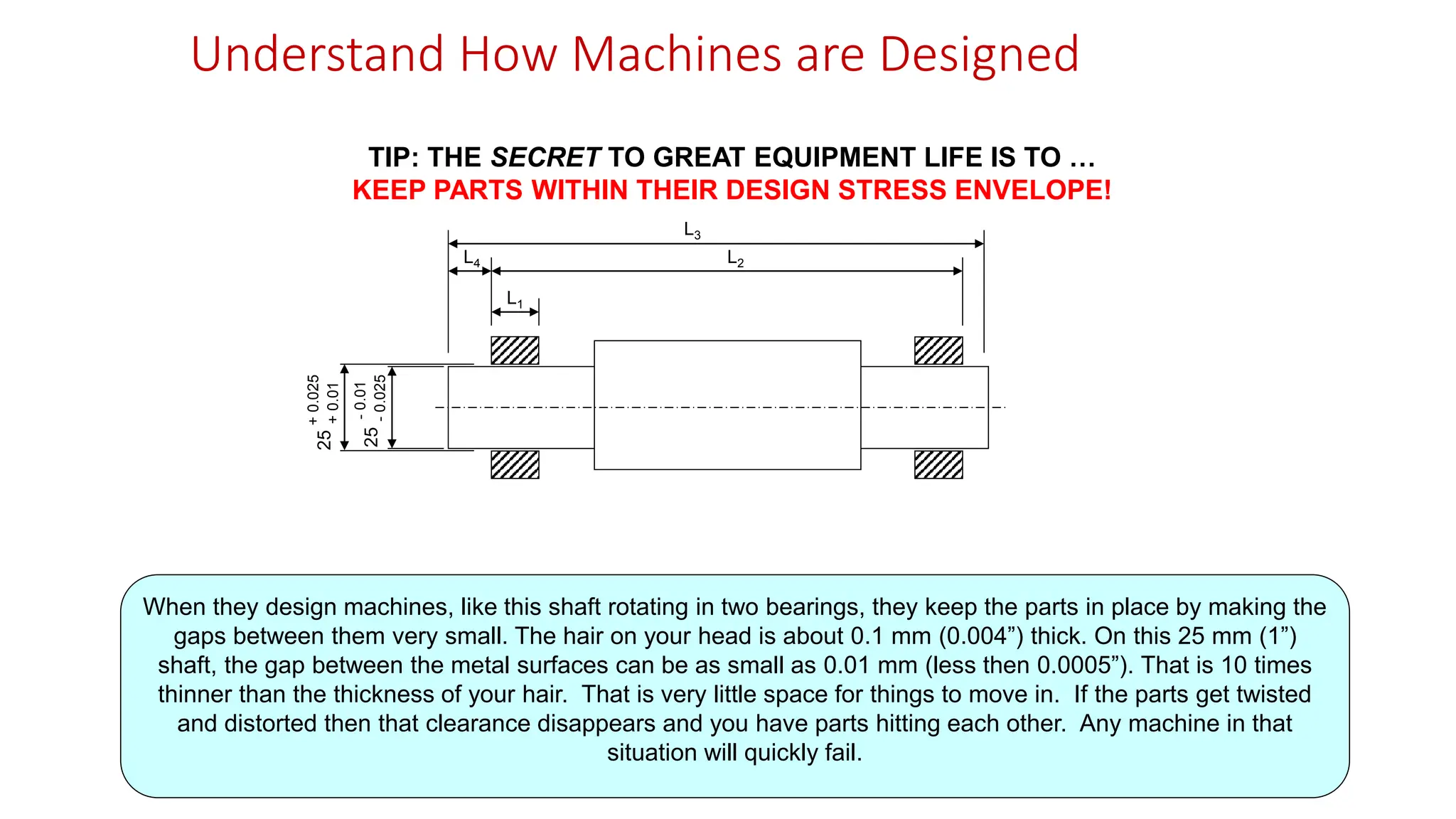

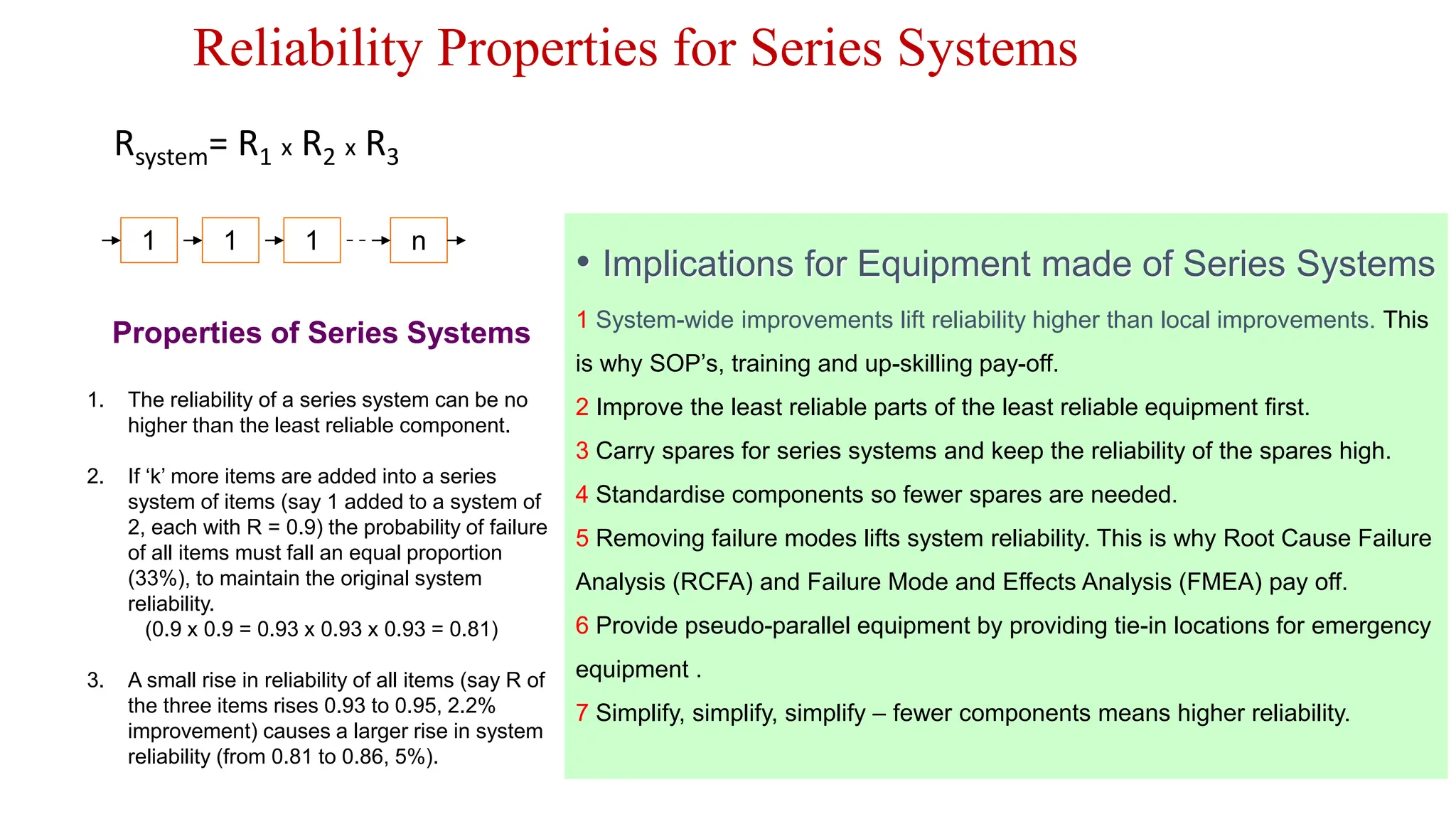

![Reliability Properties for Systems

• Series Systems

Rsystem= R1 x R2 x R3

• Parallel Systems

Rsystem= 1-[(1- R1)x(1- R2)x(1-R3)]

1

1

1

n

1 1 1 n

R = 0.95 x 0.95 = 0.9025

R = 1 – [(1 - 0.6) x (1 - 0.6)] = 0.84

The mathematics can be difficult. But you need to know that such mathematics exists

and be able to use the principles to optimise maintenance.](https://image.slidesharecdn.com/random-251120173613-daf465a2/75/slide-88-2048.jpg)

![Reliability Properties for Parallel Systems

1 1 1 n

Rsystem= 1-[(1- R1)x(1- R2)x(1-R3)]

Properties of Parallel Systems

1. The more number of components in

parallel the higher the system reliability.

2. The reliability of the parallel arrangement

is higher than the reliability of the most

reliable component.

m

m m

m

m

m m

m

Which arrangement is more reliable if m = 0.9?

• Implications of Parallel Systems for

Equipment

1 Use parallel arrangements when the risk of failure has high DAFT

Cost consequences.

2 Consider providing various paths for product to take in production

plants with in-series equipment.

3 Build redundancy into your systems so there is more than one

way to do a thing.](https://image.slidesharecdn.com/random-251120173613-daf465a2/75/slide-90-2048.jpg)

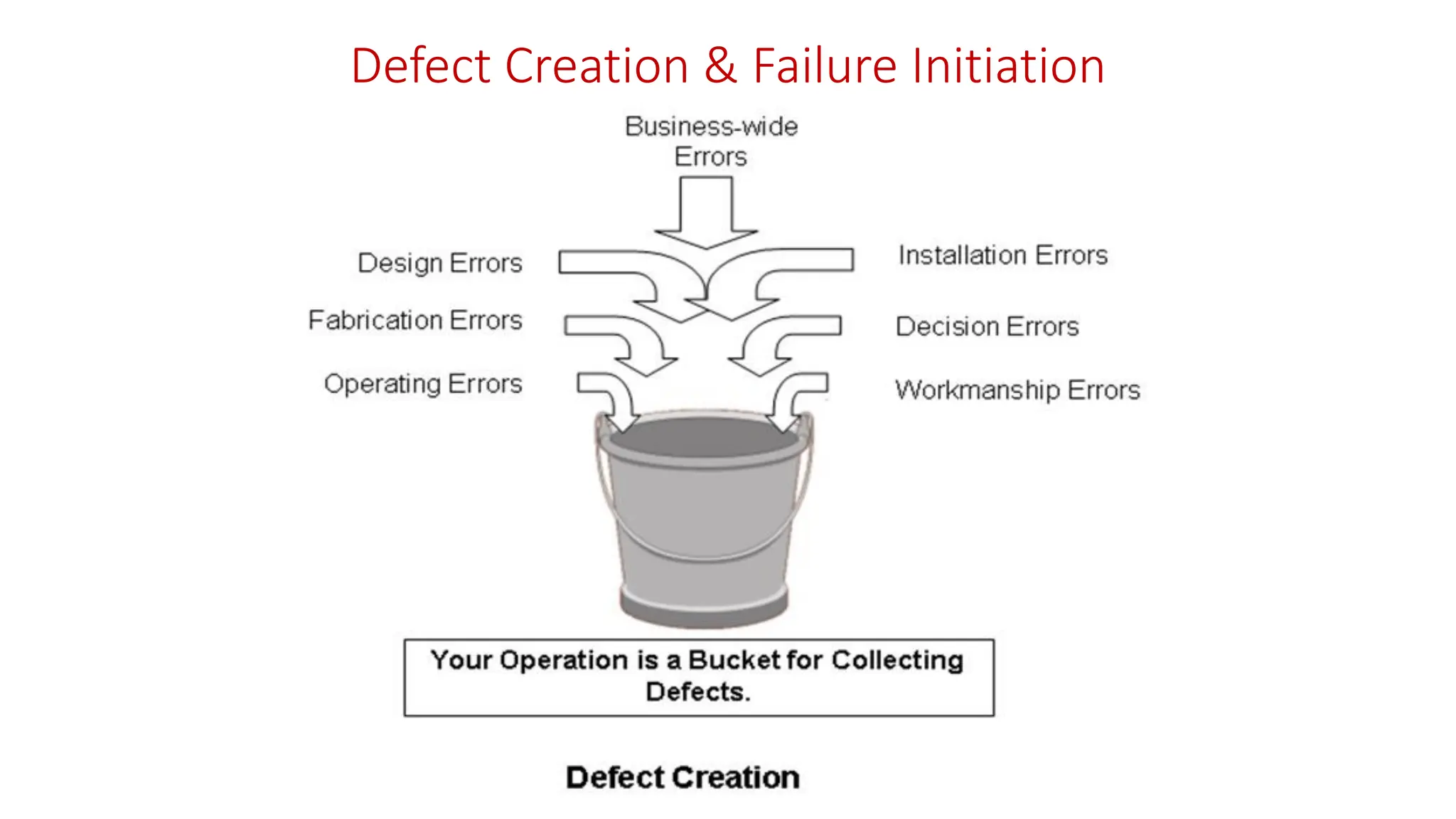

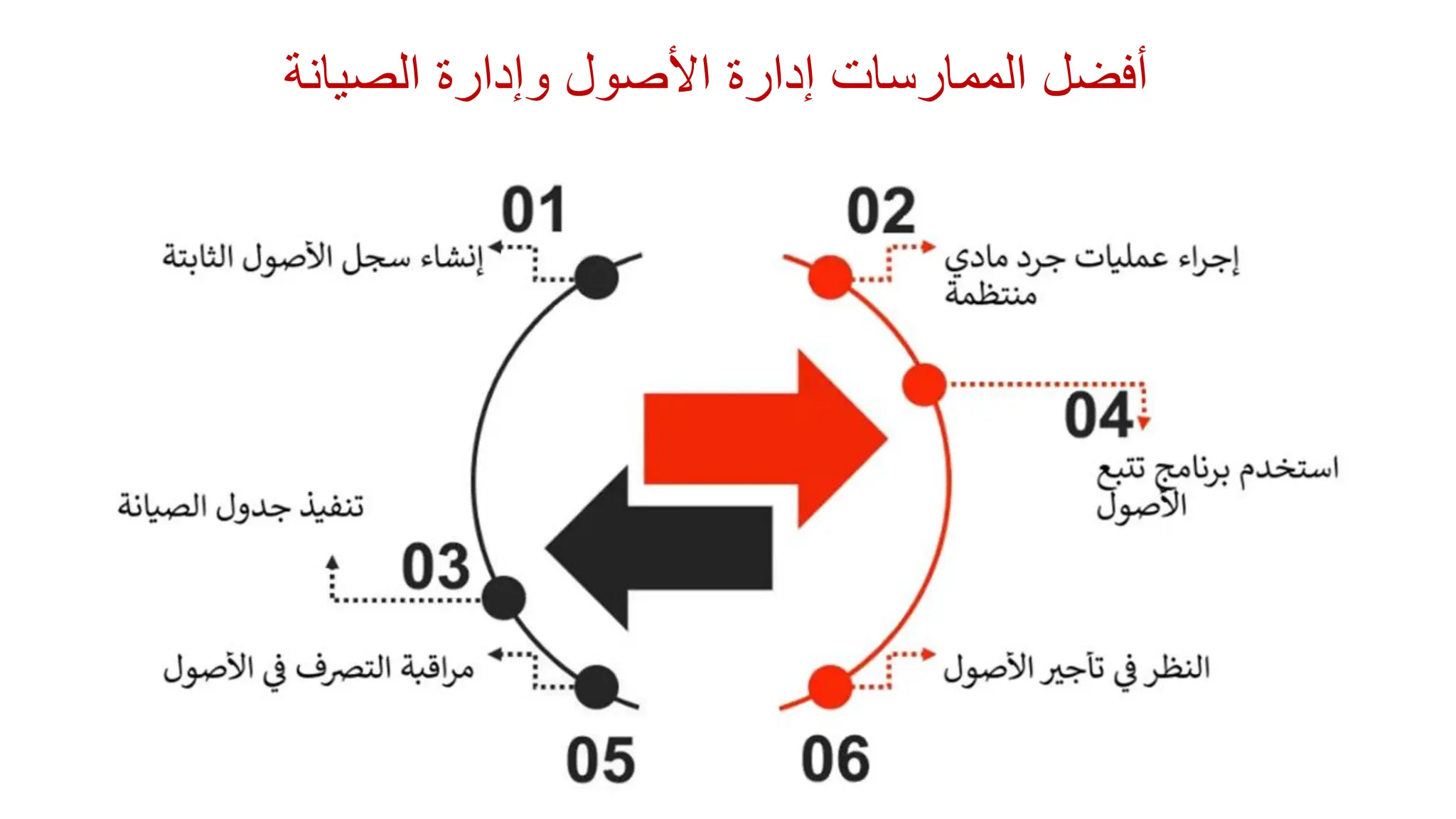

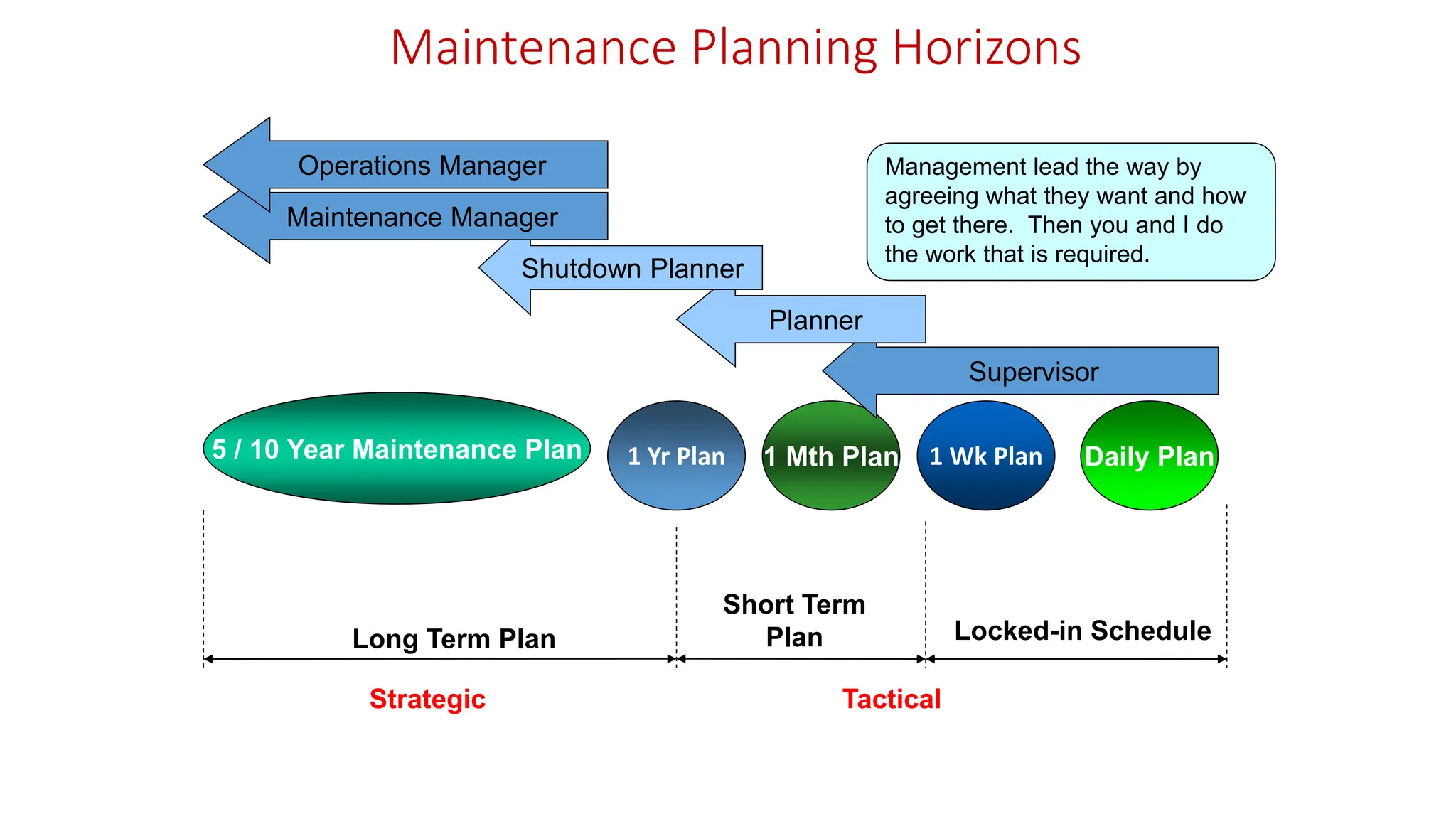

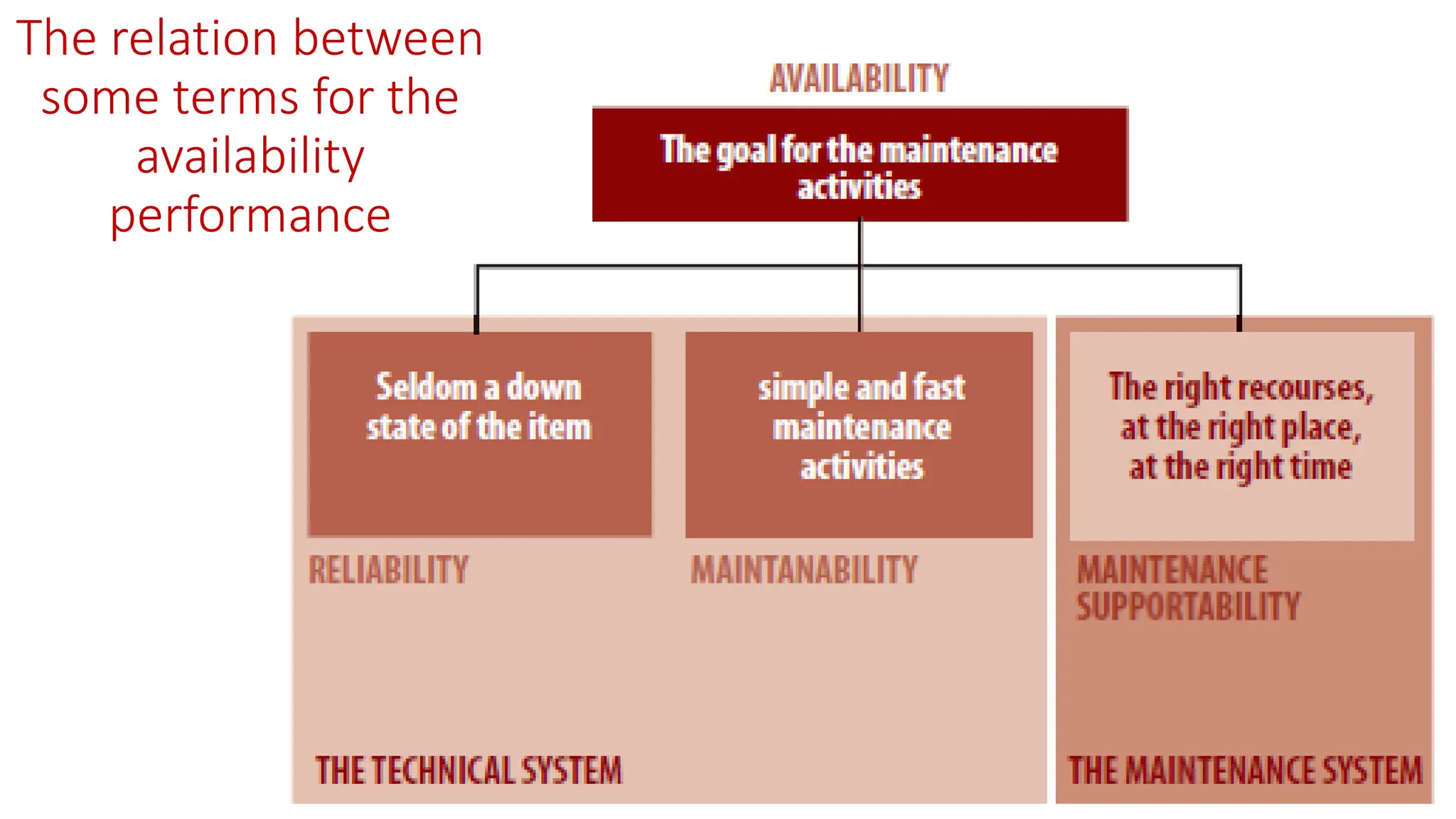

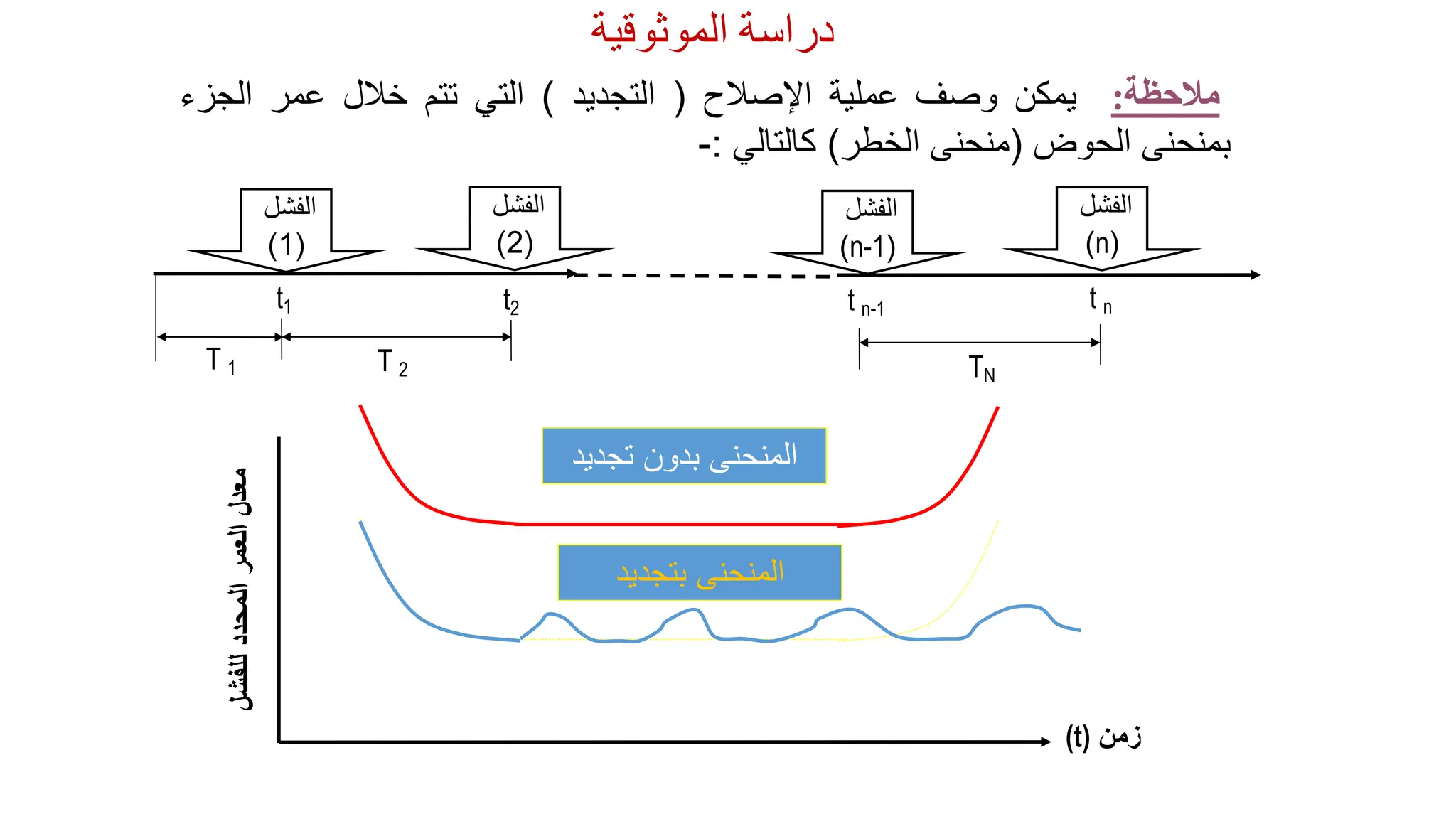

![دراسة

الموثوقية

تعرف

اإلتاحة

بمقدار

االستعداد

واحتمالية

اتاحتها

للعمل

تحت

الطلب؛

ومفهو

م

اإلتاحة

يجمع

ما

بين

الموثوقية

وقابلية

الصيانة

حيث

يعبر

عنها

بالتالي

:

3

-

اإلتاحة

ِ

Availability

MTTR

MTBF

MTBF

A

حيث

MTBF

=

متوسط

الزمن

بين

األعطال

(

الفشل

)

MTTR

=

متوسط

الزمن

لإلصالح

وعليه

تعتمد

اإلتاحة

على

مقدار

موثوقية

المعدة

أو

الجزء

للعمل

,

ومقدار

الزمن

الم

طلوب

للقيام

باإلصالح

وهي

تتأثر

بالتالي

:

مقدار

اإلتاحة

لقطع

الغيار

ويحسب

من

احتمالية

توفر

مستويات

االستيداع

.

عامل

االستخدام

=

{

زمن

التشغيل

(t1)

[/

زمن

التشغيل

(t1)

+

زمن

الصيانة

(t2)

+

زمن

توقف

(t3)

]

}

مقدار

إتاحة

افراد

الصيانة

ويحسب

وفقا

الحتمال

توفر

العمالة

المتخصصة

.](https://image.slidesharecdn.com/random-251120173613-daf465a2/75/slide-106-2048.jpg)