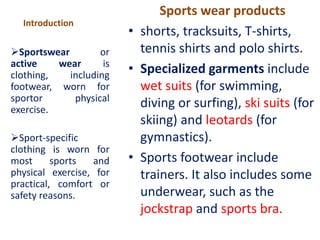

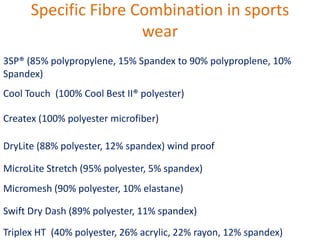

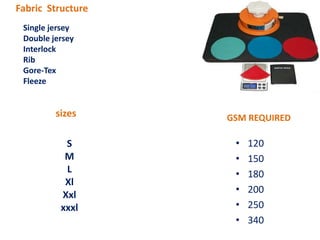

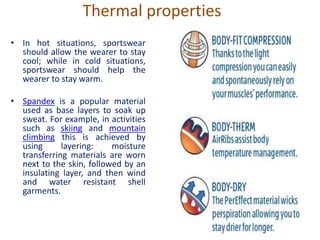

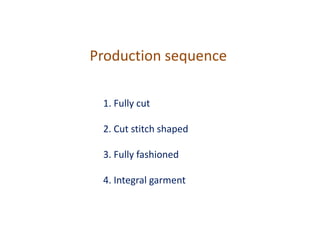

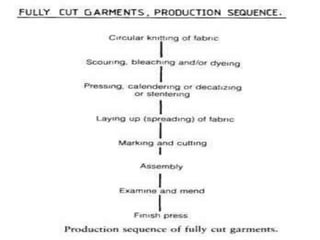

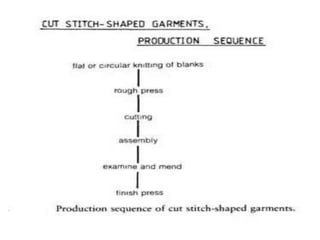

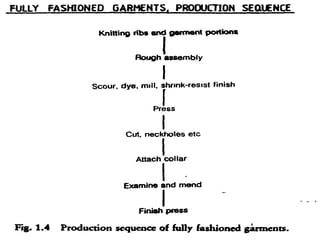

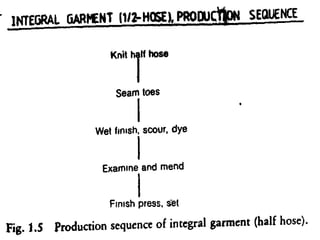

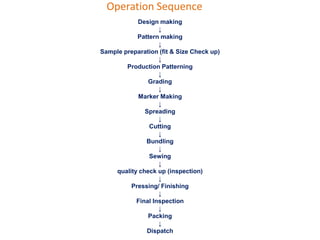

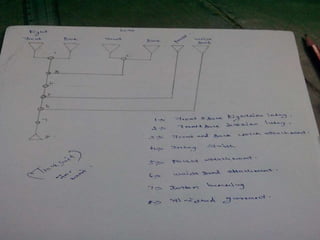

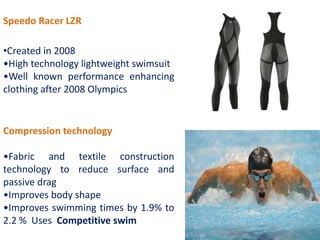

This document discusses sports garments and fabrics. It provides classifications of sportswear including items for swimming, skiing, football and more. It describes requirements for sports fabrics including strength, durability and moisture wicking properties. Specific fabric blends are listed for activities like running and cycling. The document outlines the production process for sportswear and discusses how certain high-tech garments have been shown to improve athletic performance in swimming, powerlifting and soccer.