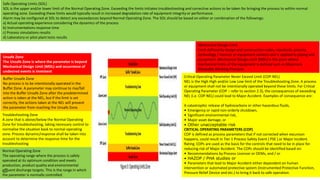

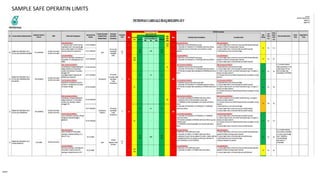

Safe Operating Limits (SOL) are established for critical process parameters based on equipment design limits and process dynamics. SOL values define normal operating zones and are documented in procedures to guide operator response. They support HAZOP analysis and management of change evaluations to ensure safe process operation.