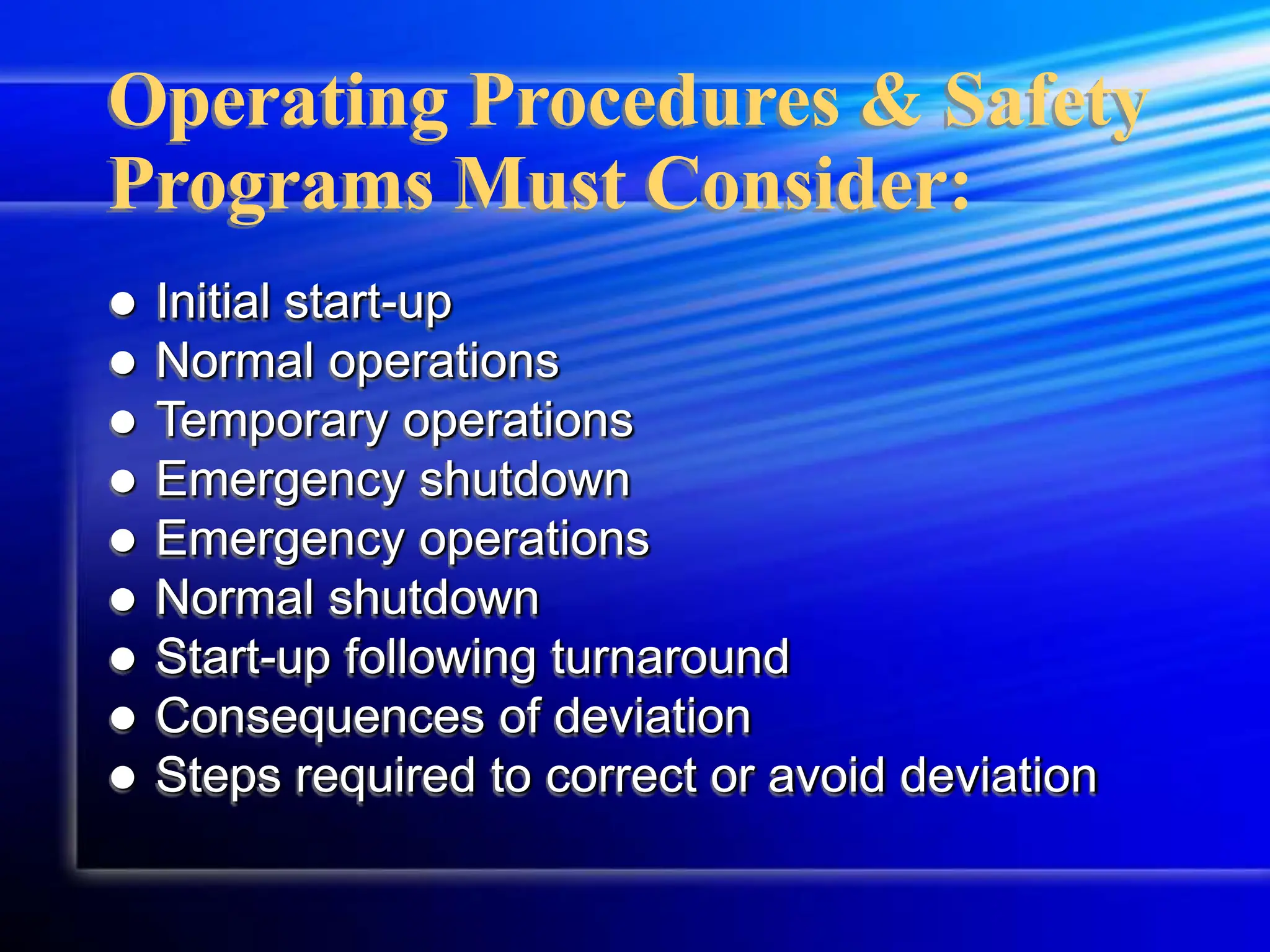

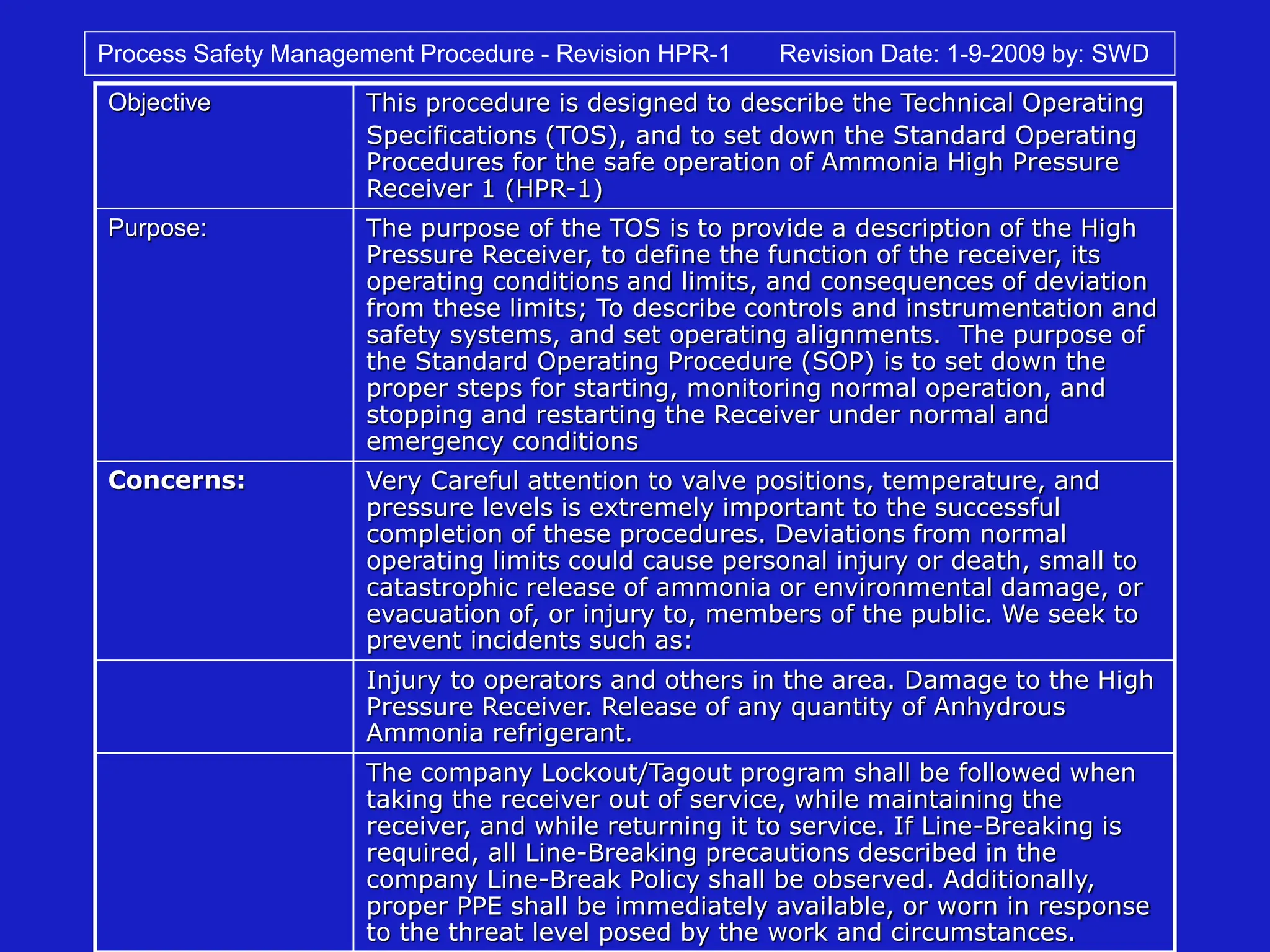

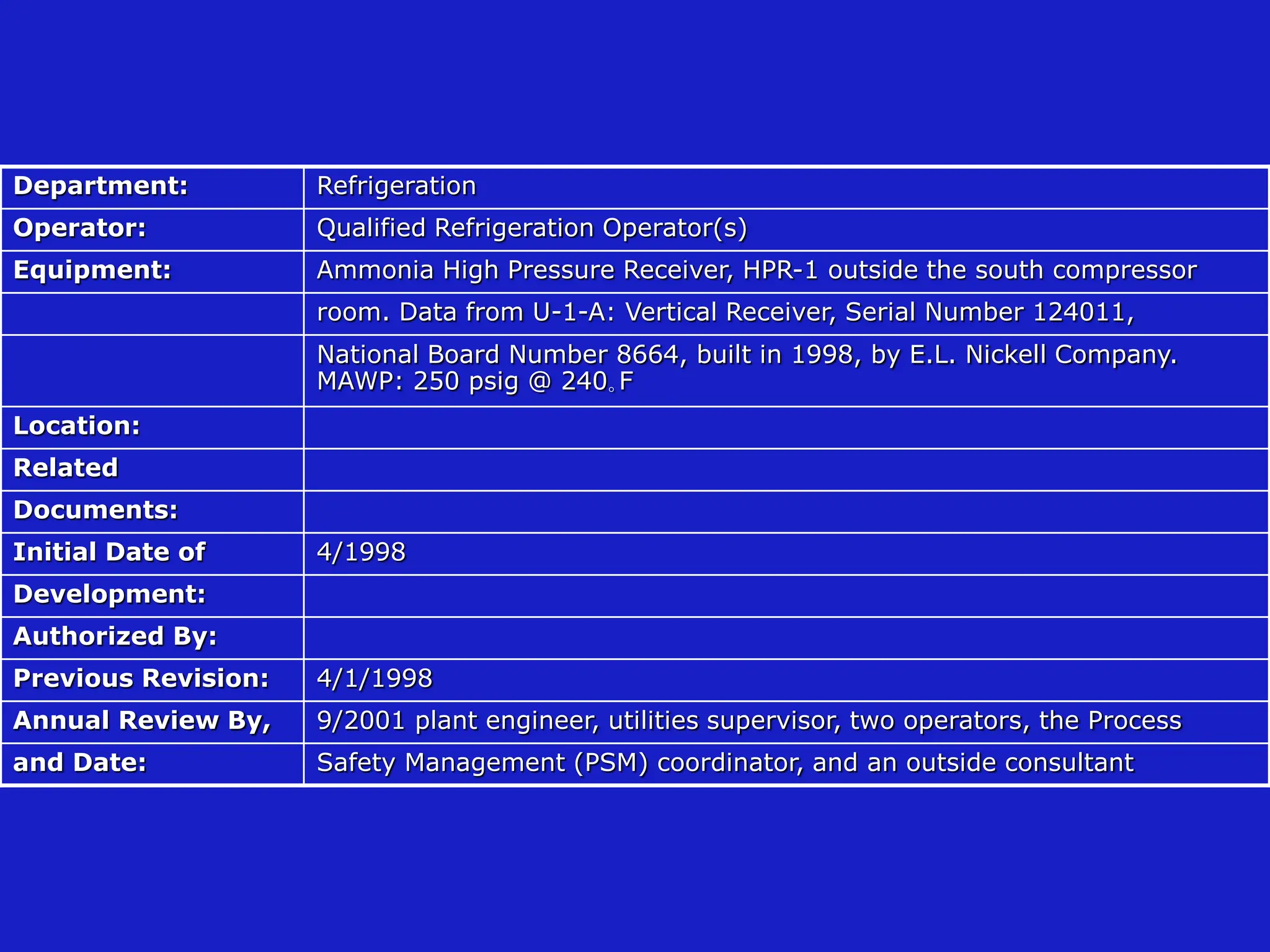

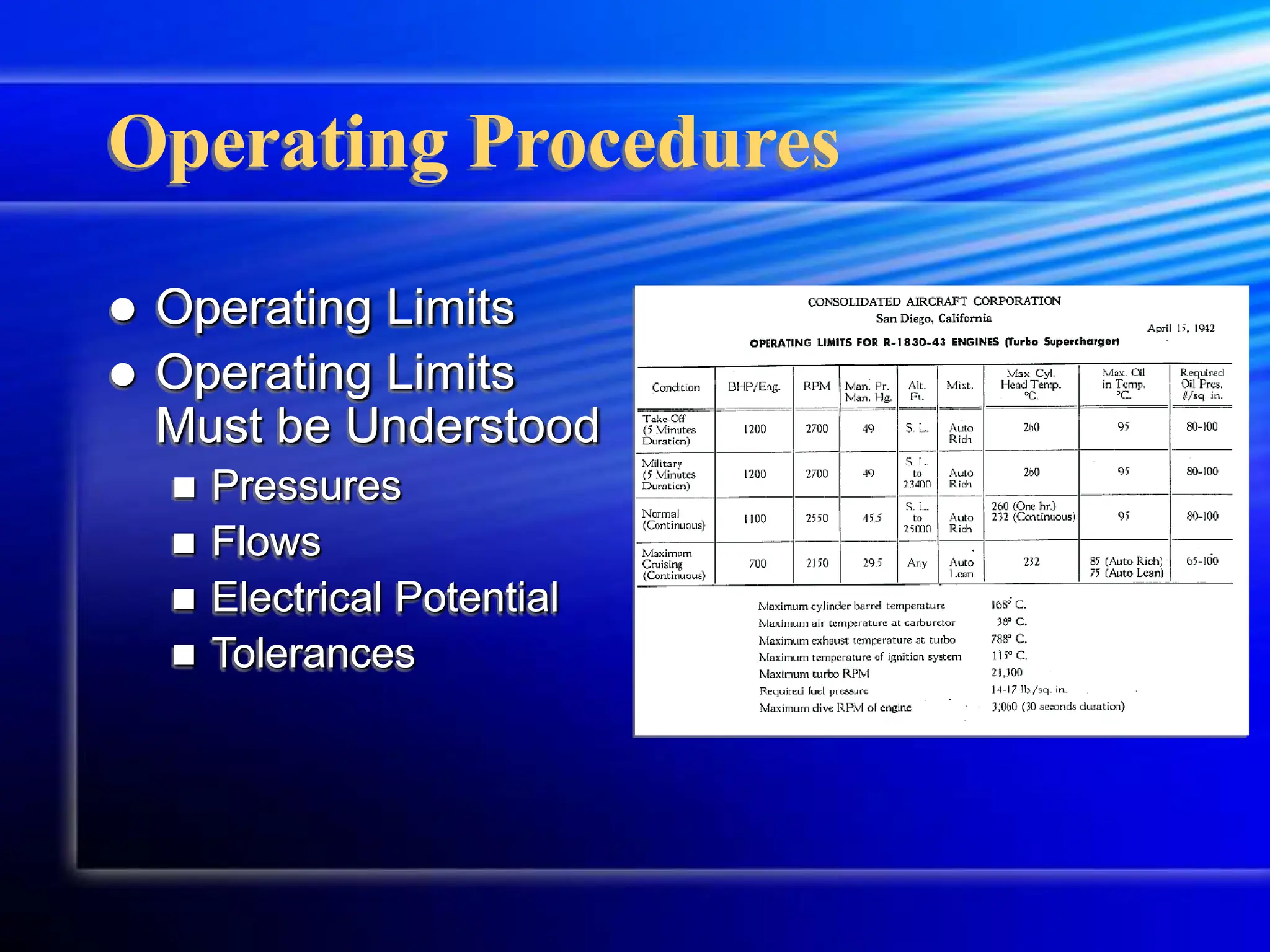

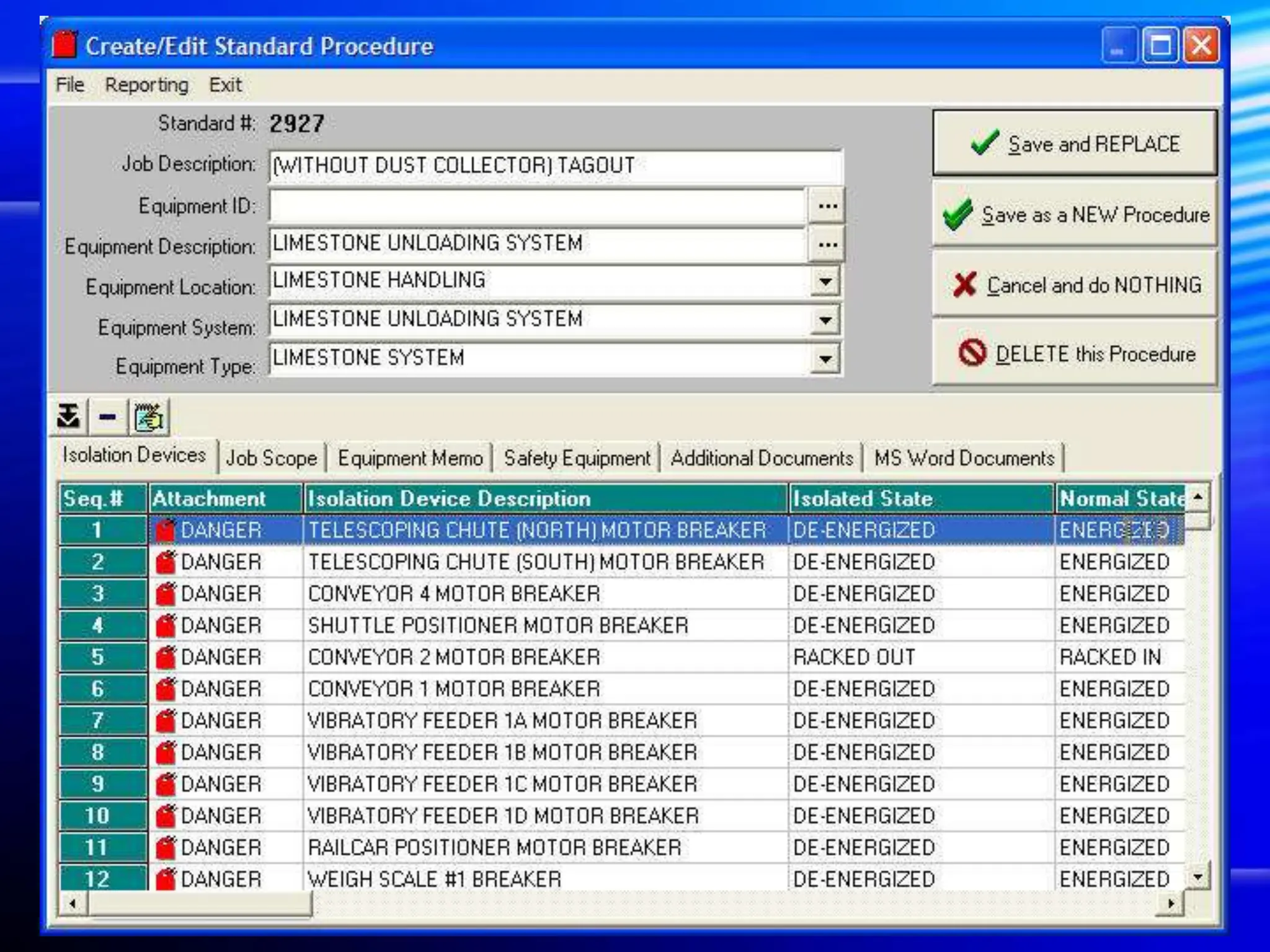

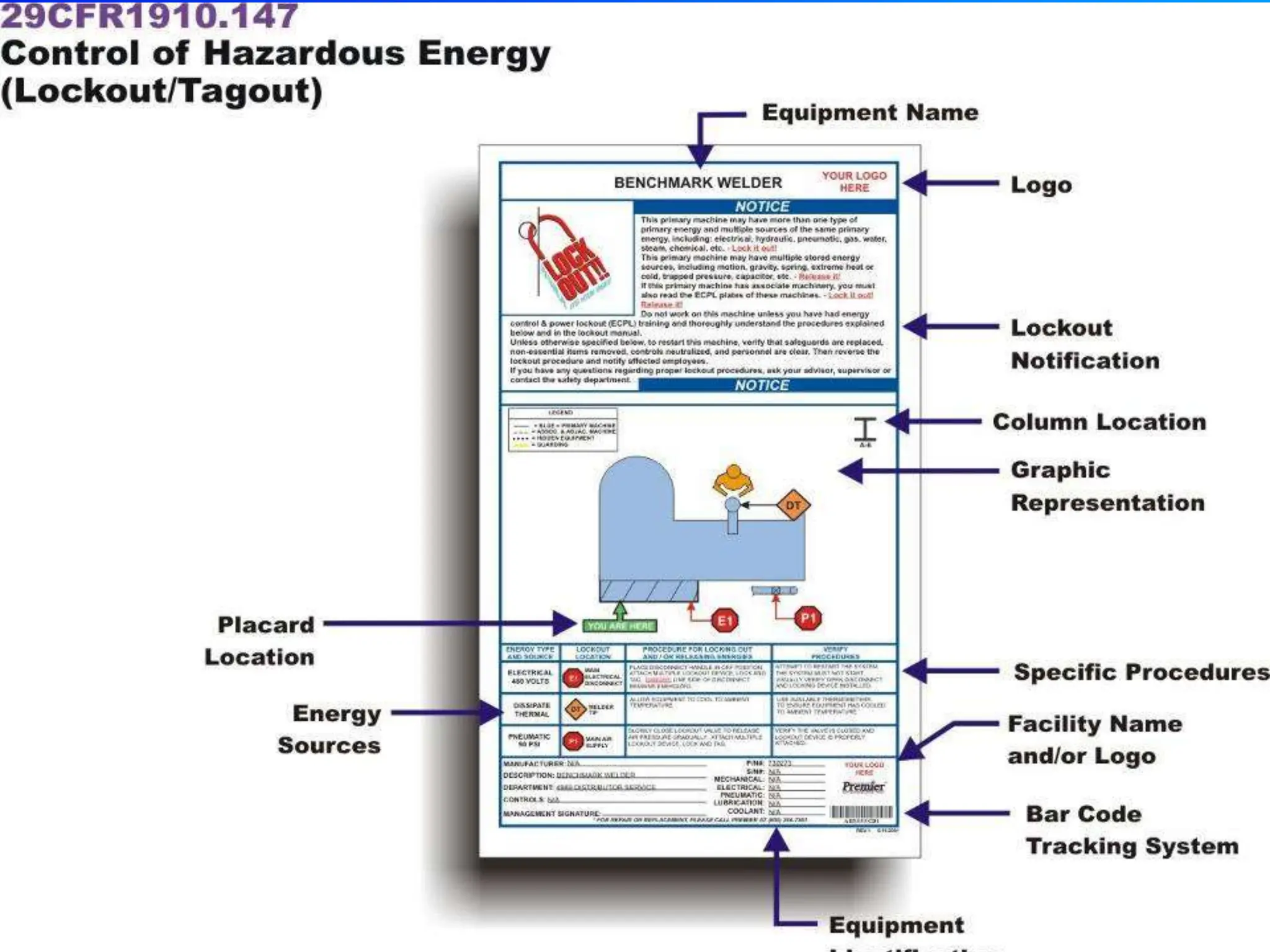

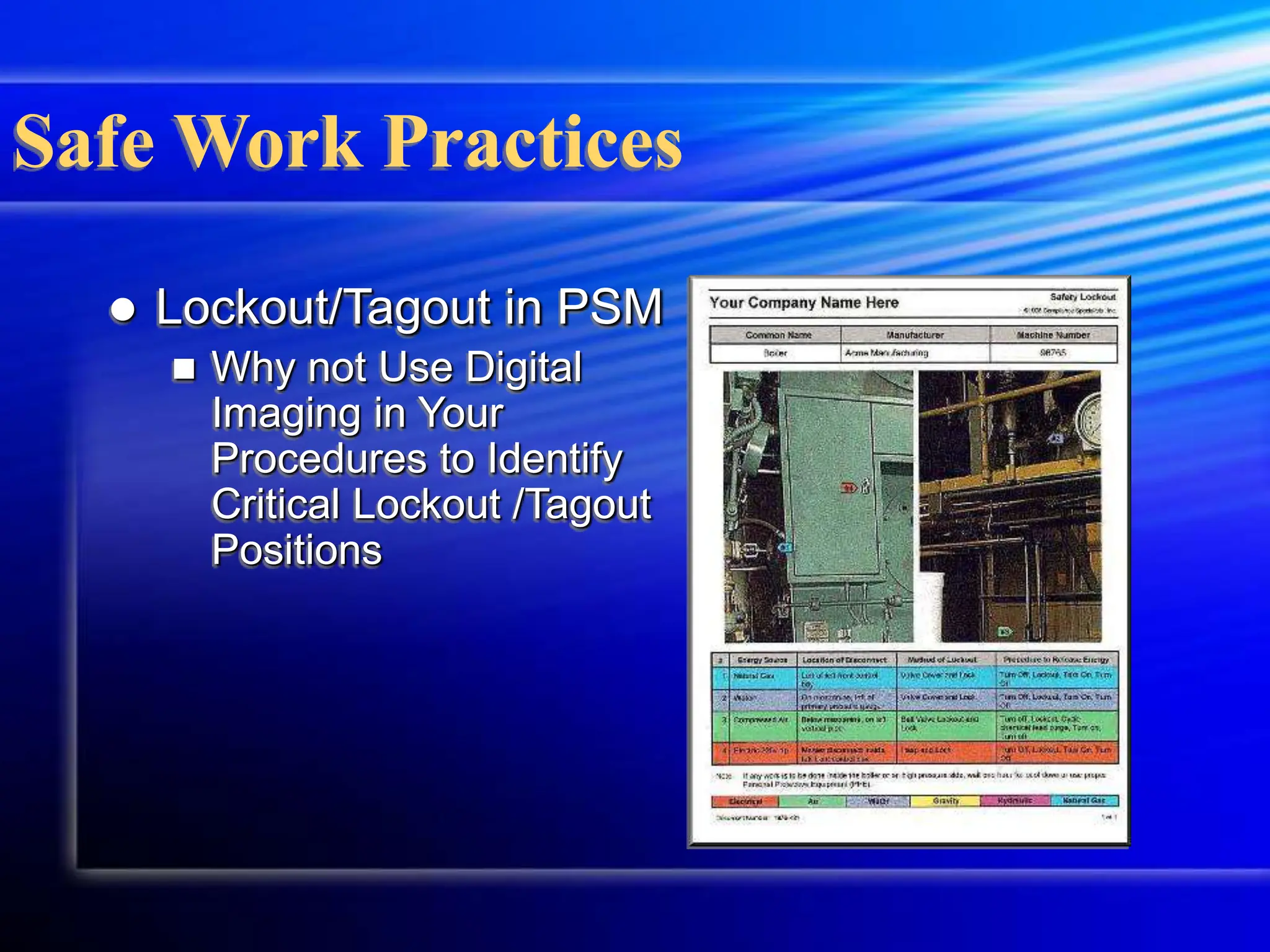

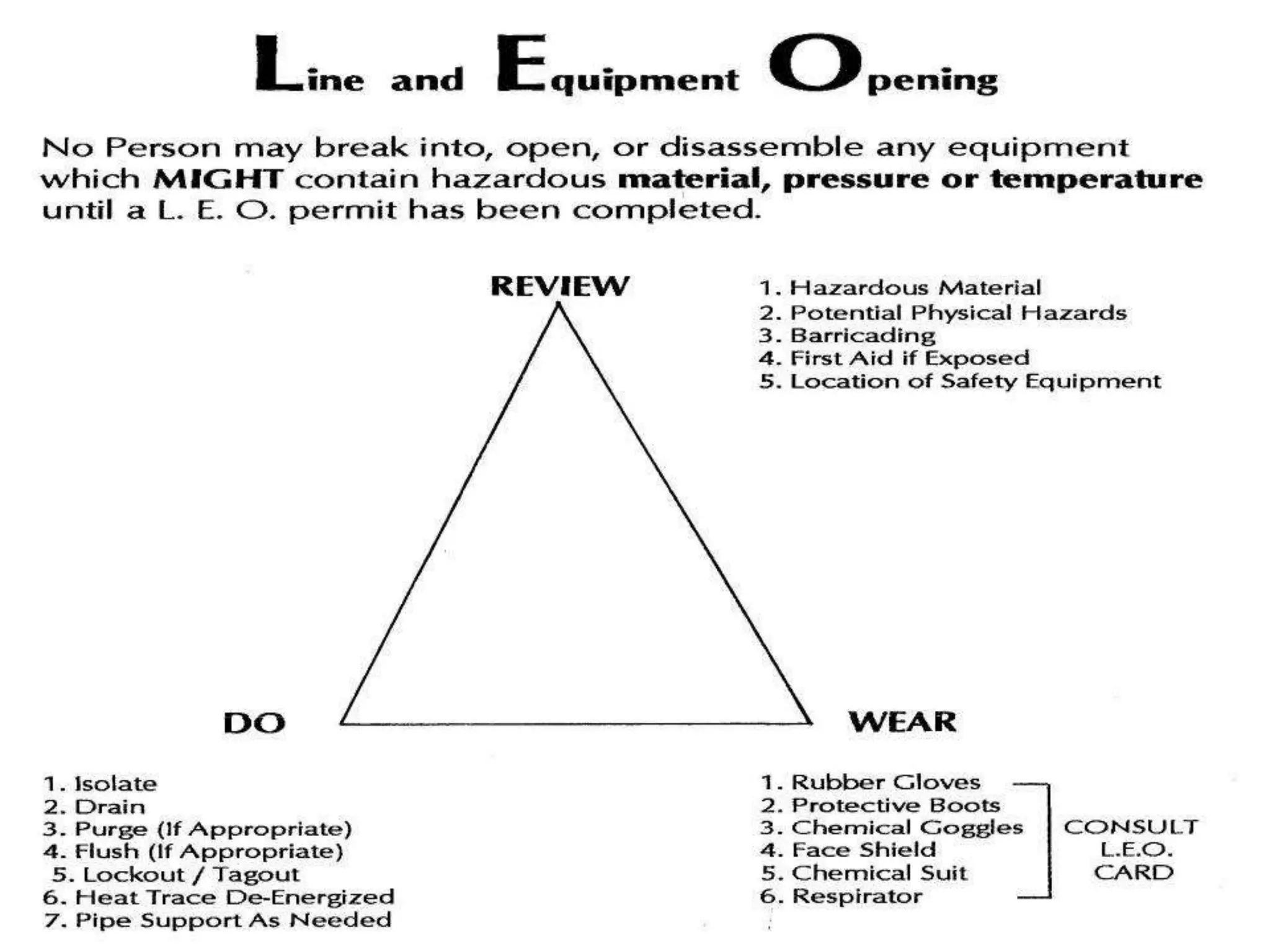

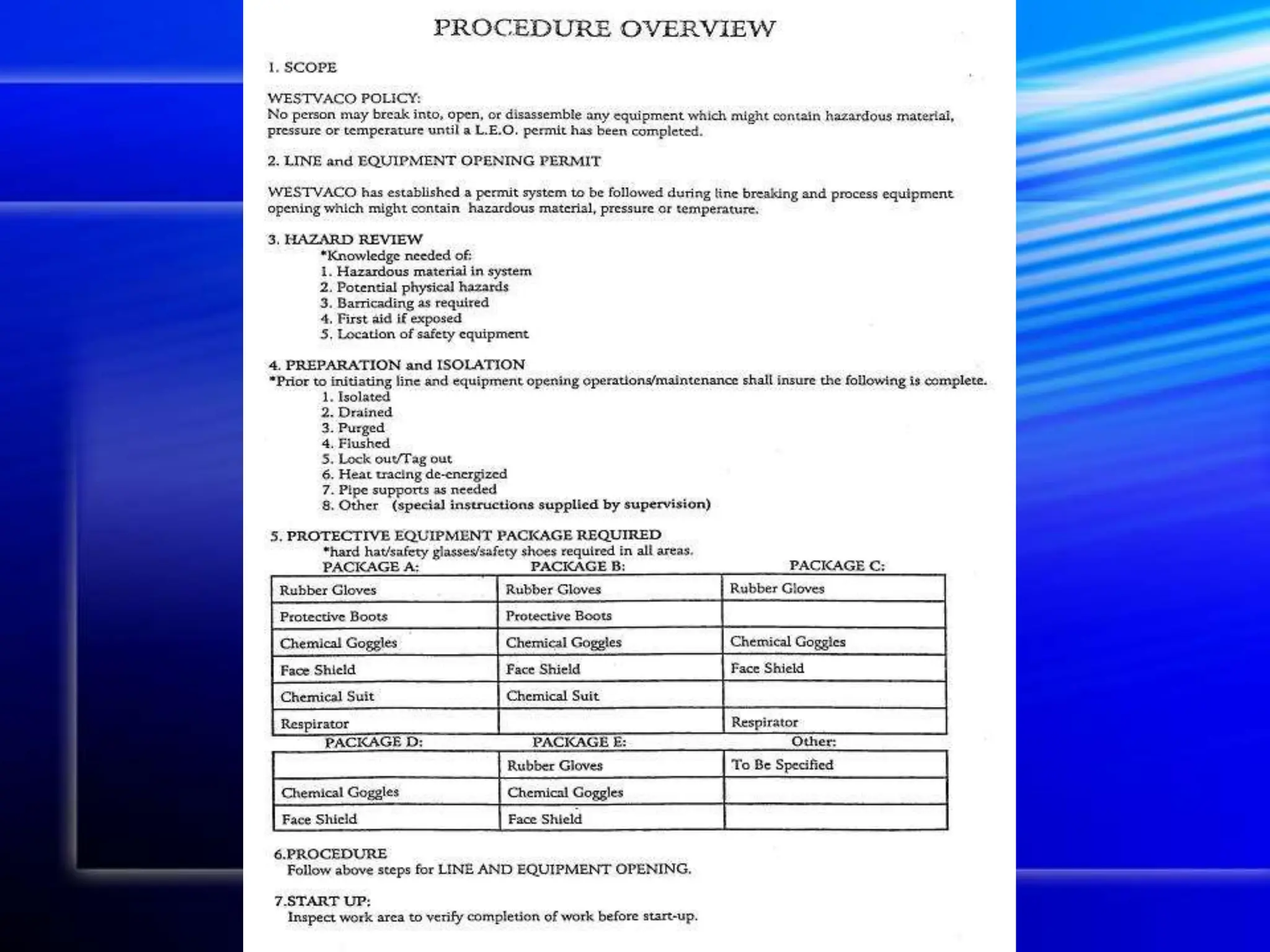

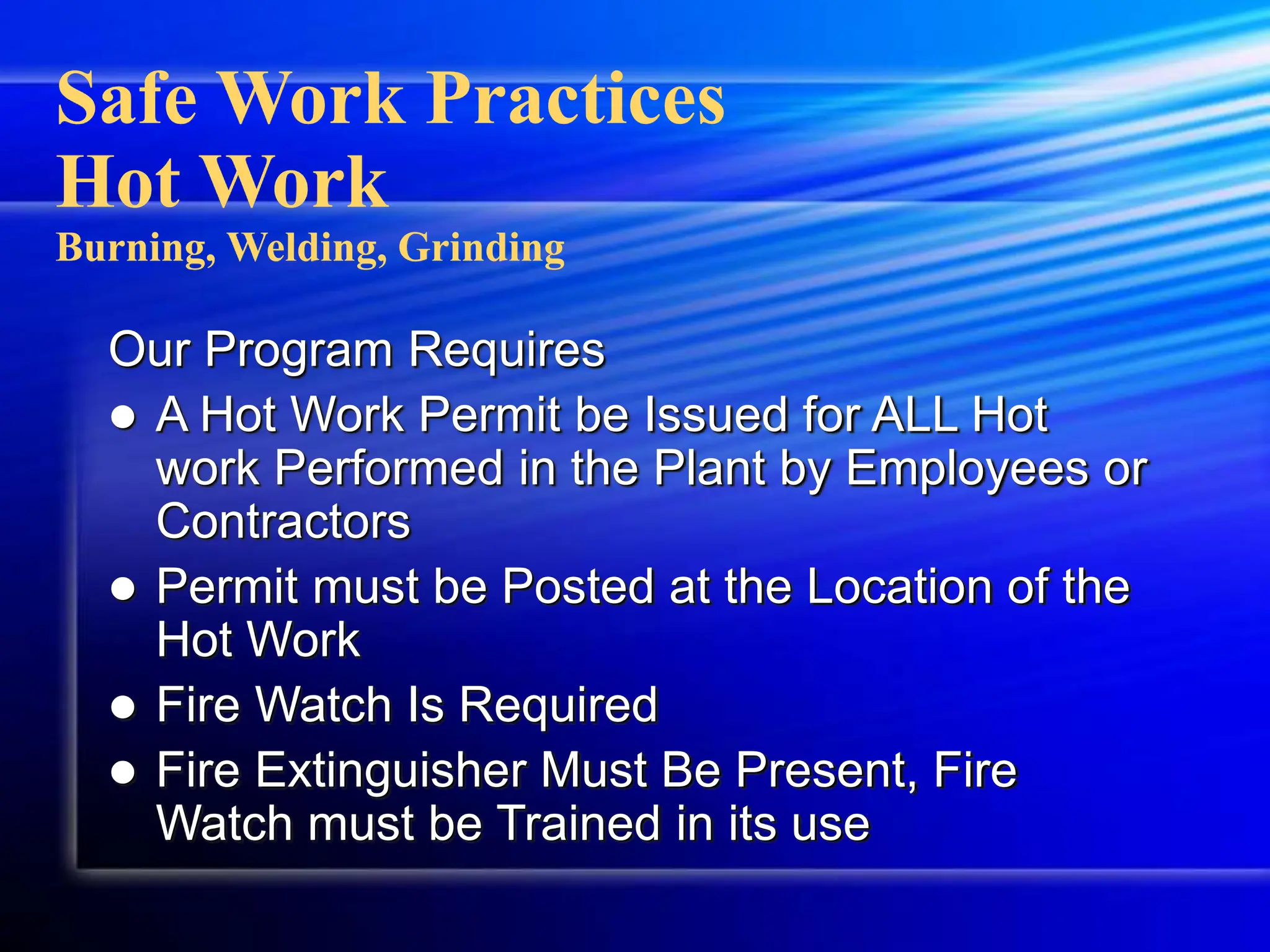

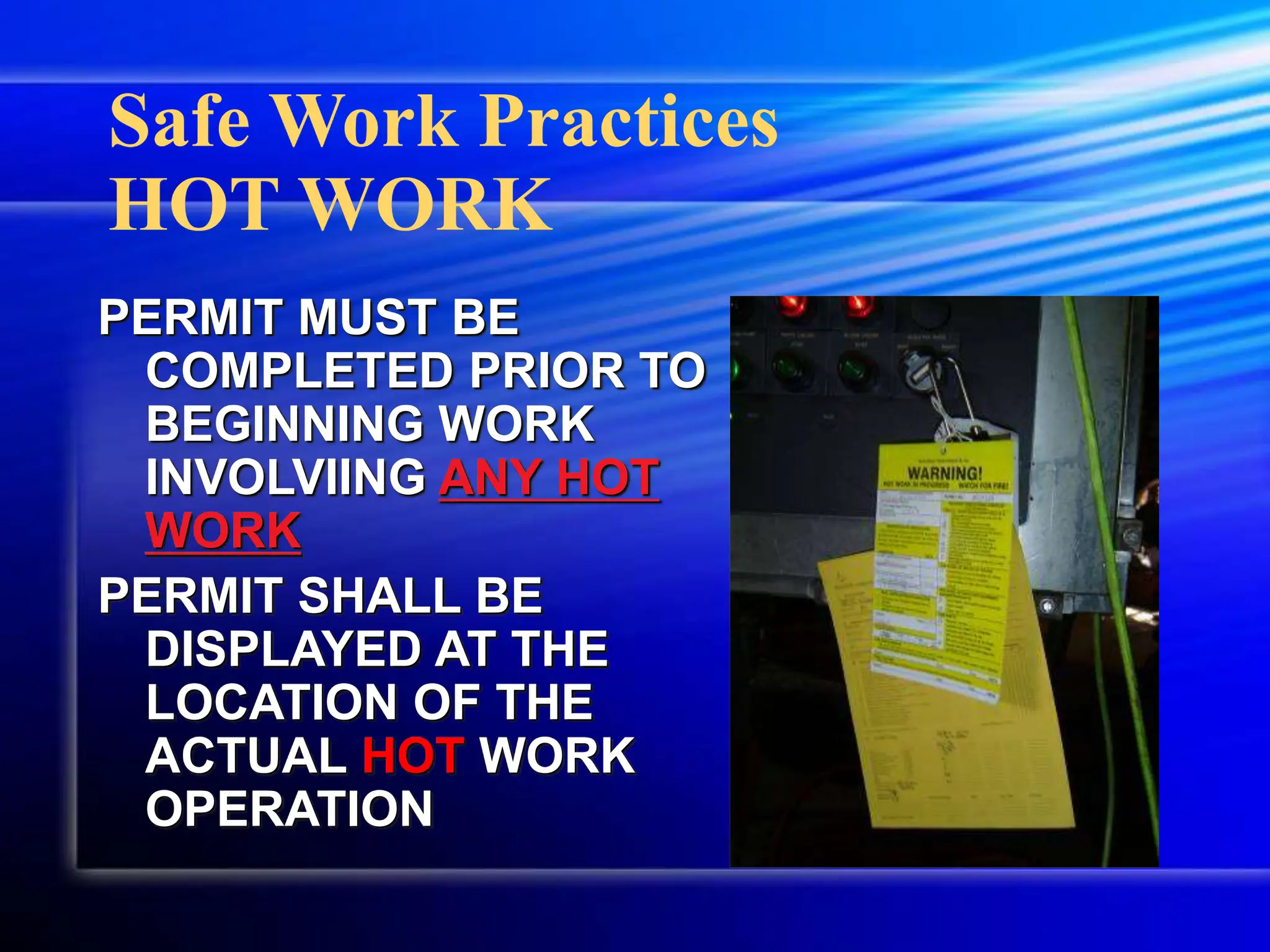

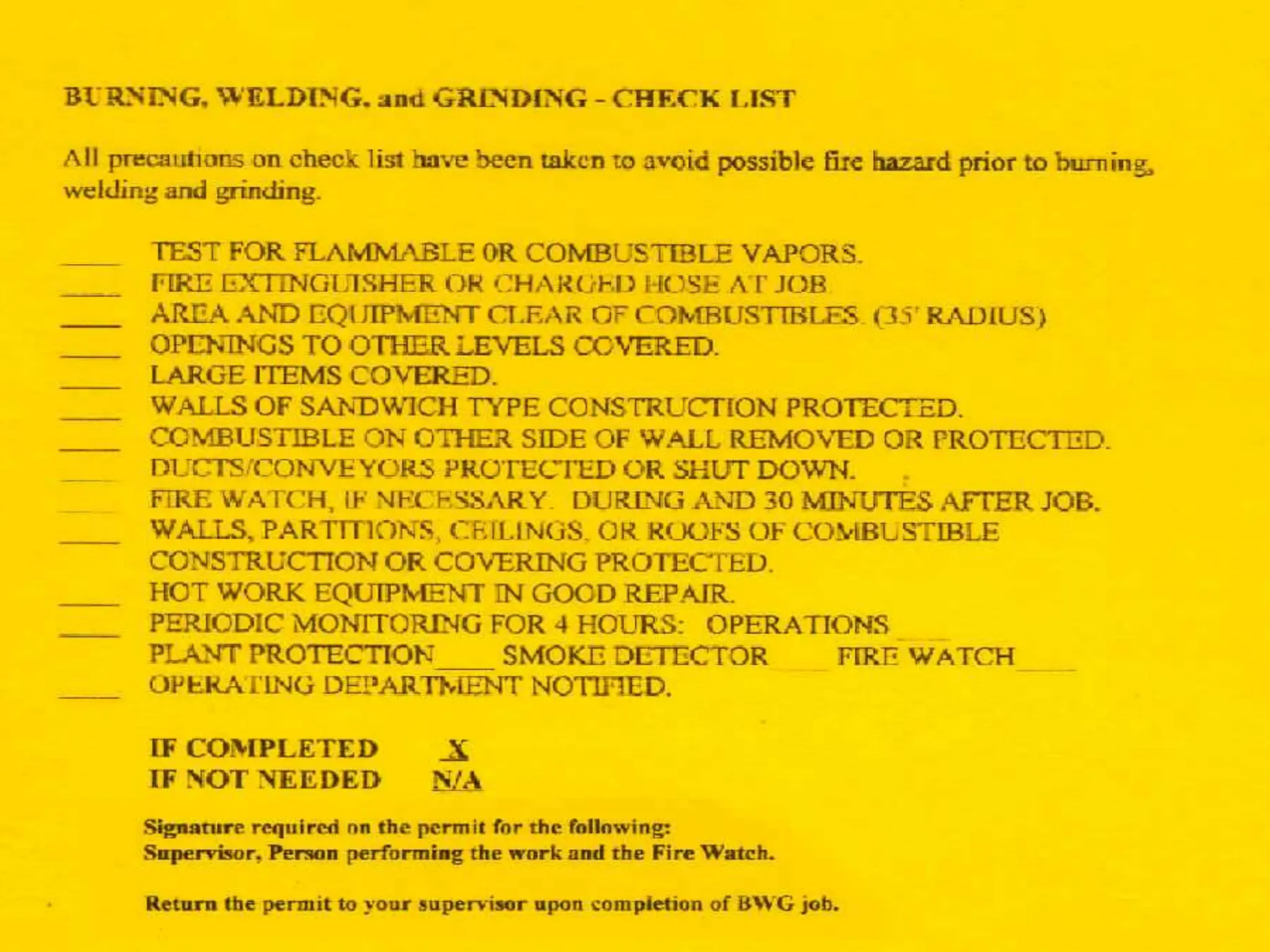

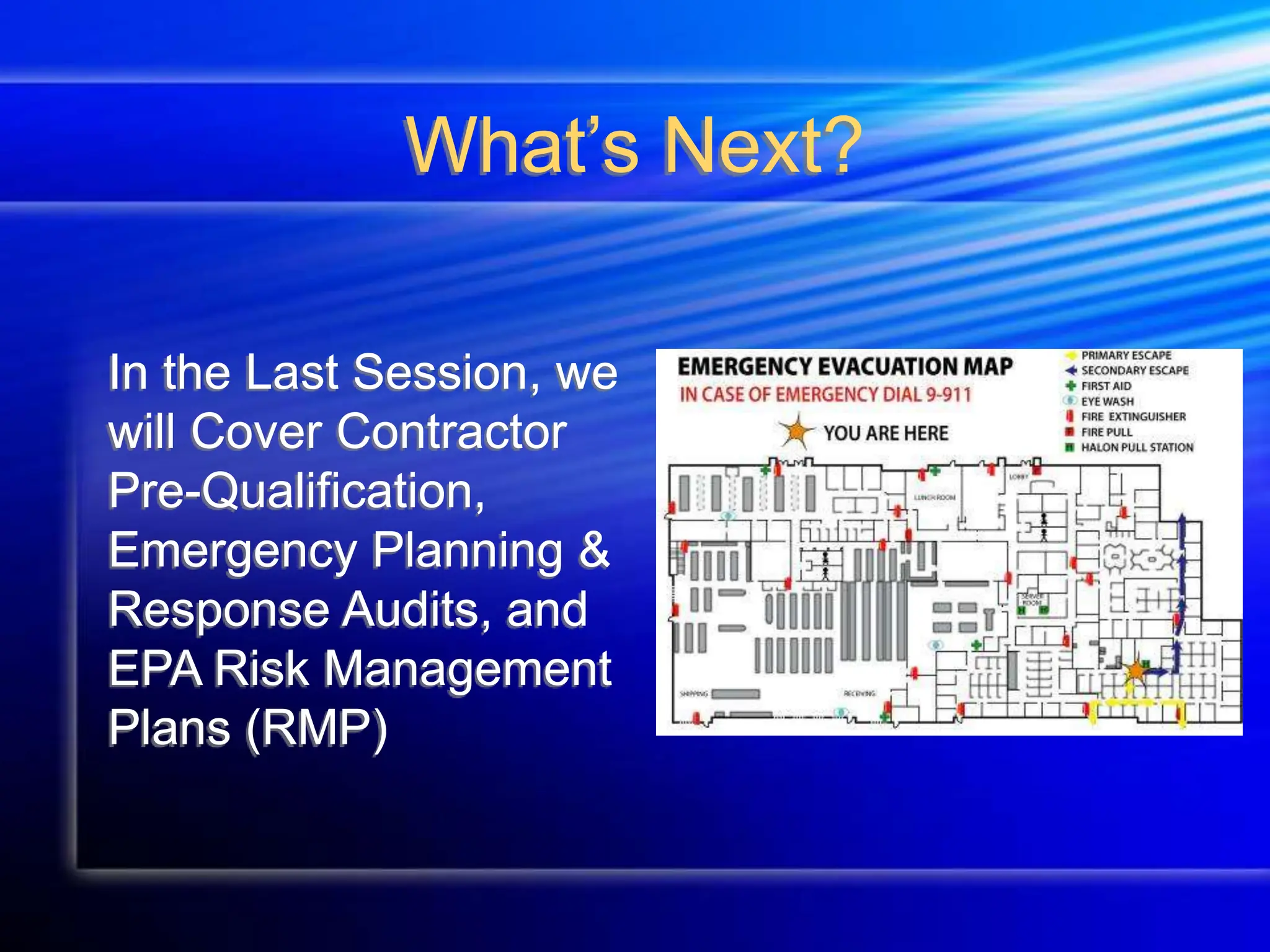

The document outlines the necessity for developing and implementing operating procedures and safety programs for the management of highly hazardous and explosive chemicals, emphasizing initial start-up, normal operations, emergency procedures, and safety work practices. It stresses the importance of training for employees on safe practices, including lockout/tagout and hot work procedures, ensuring documentation and compliance with process safety management (PSM) regulations. Following comprehensive safety and training protocols is critical to prevent incidents and ensure safe operations within chemical facilities.