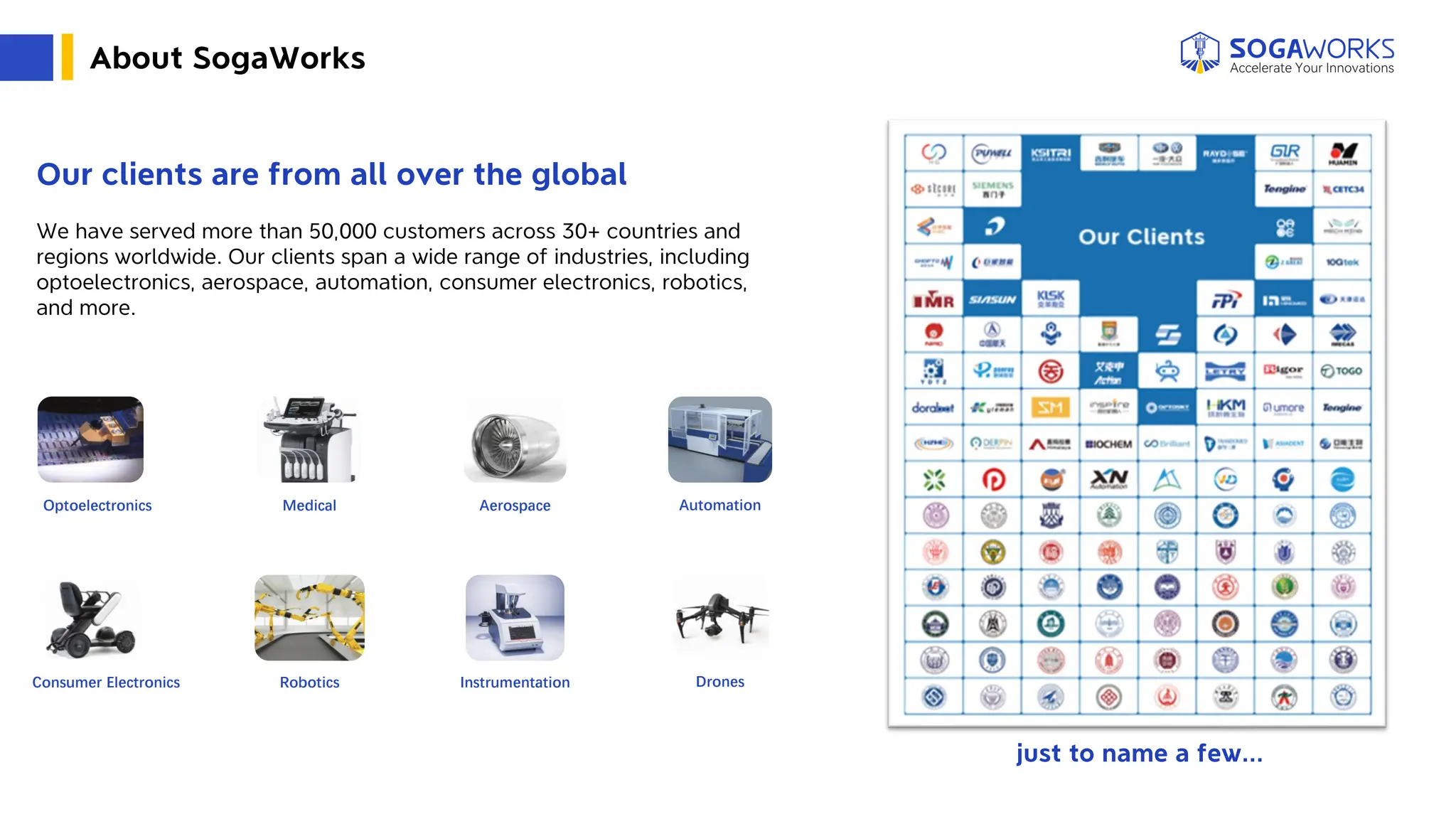

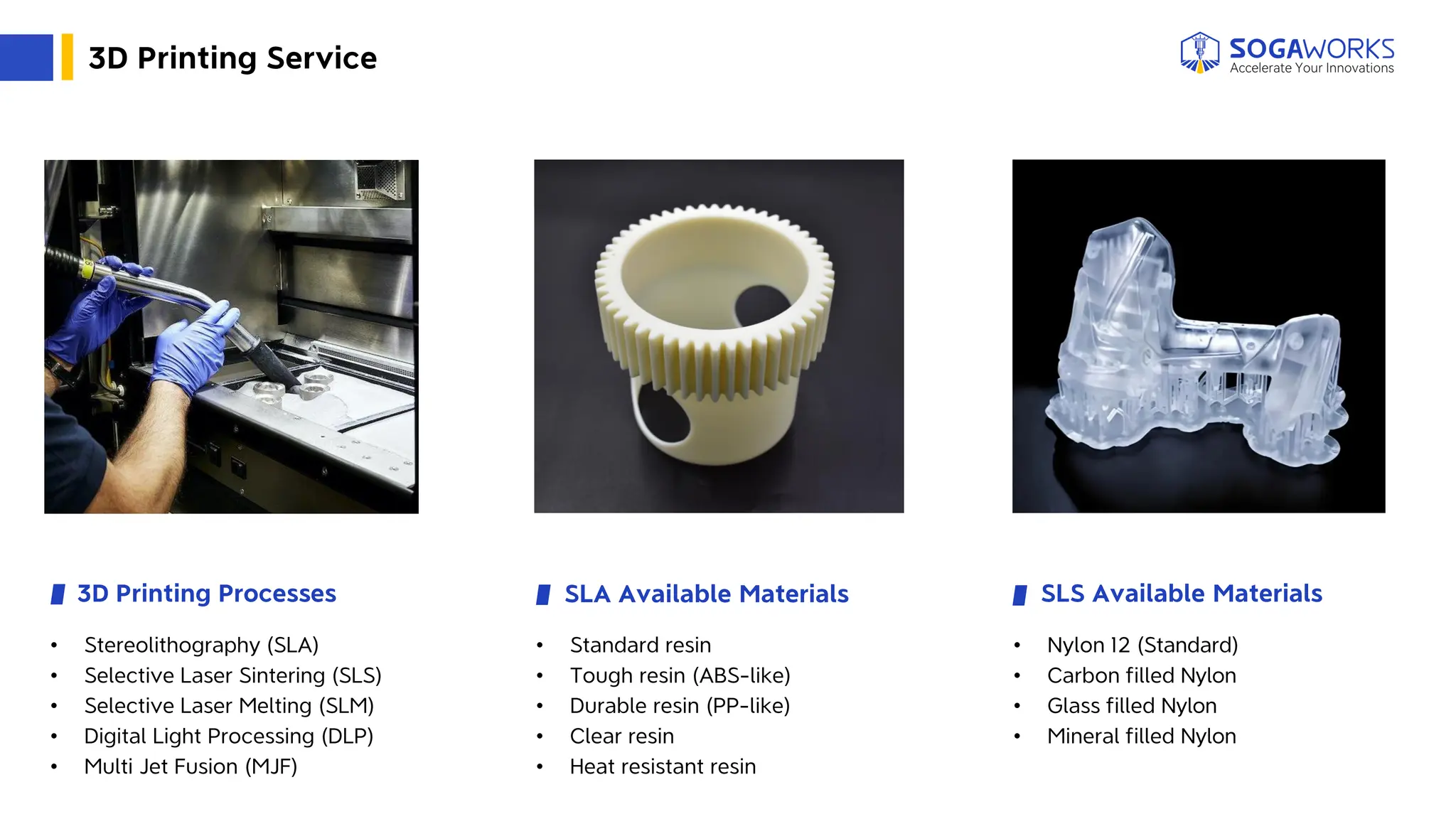

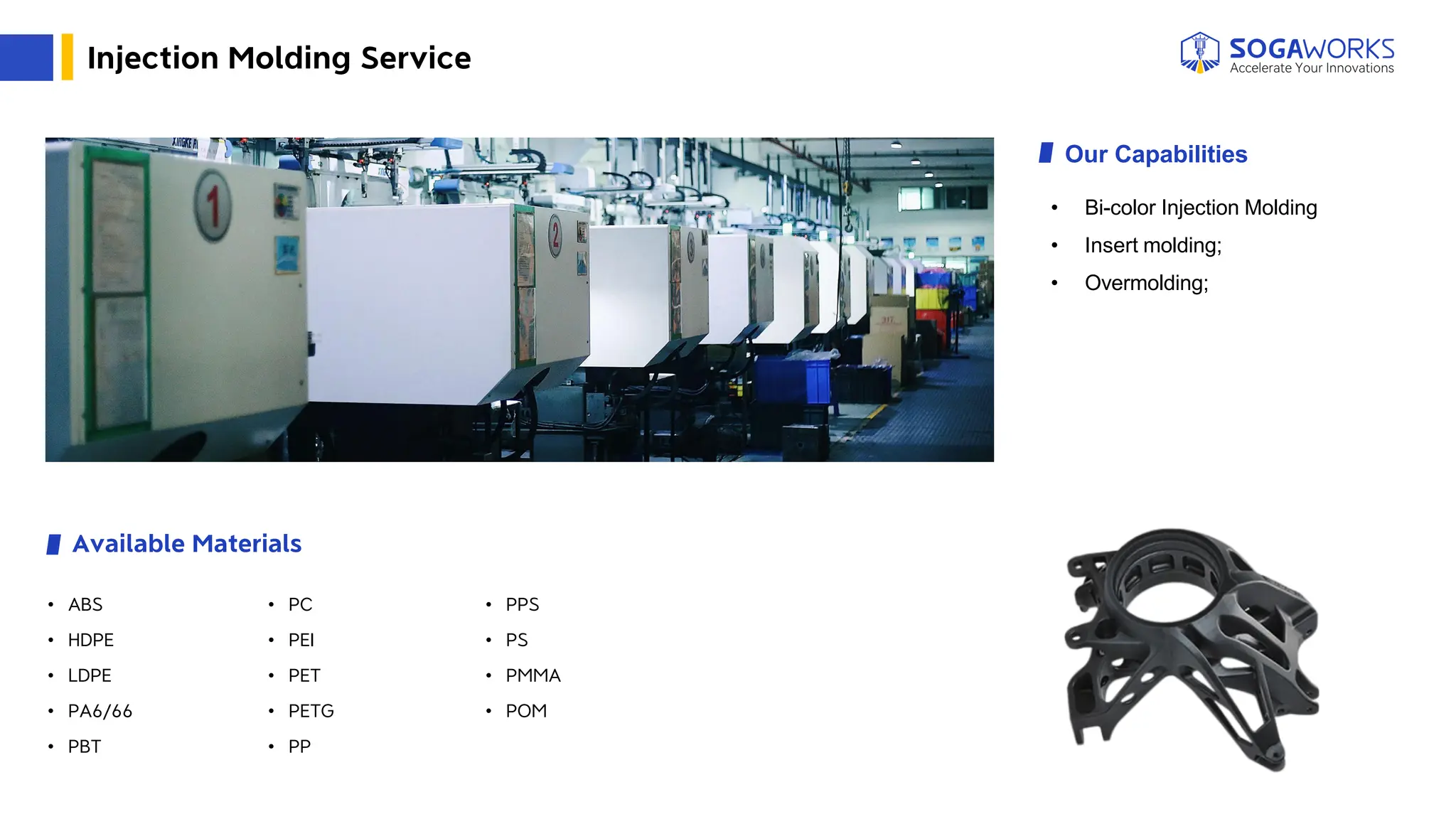

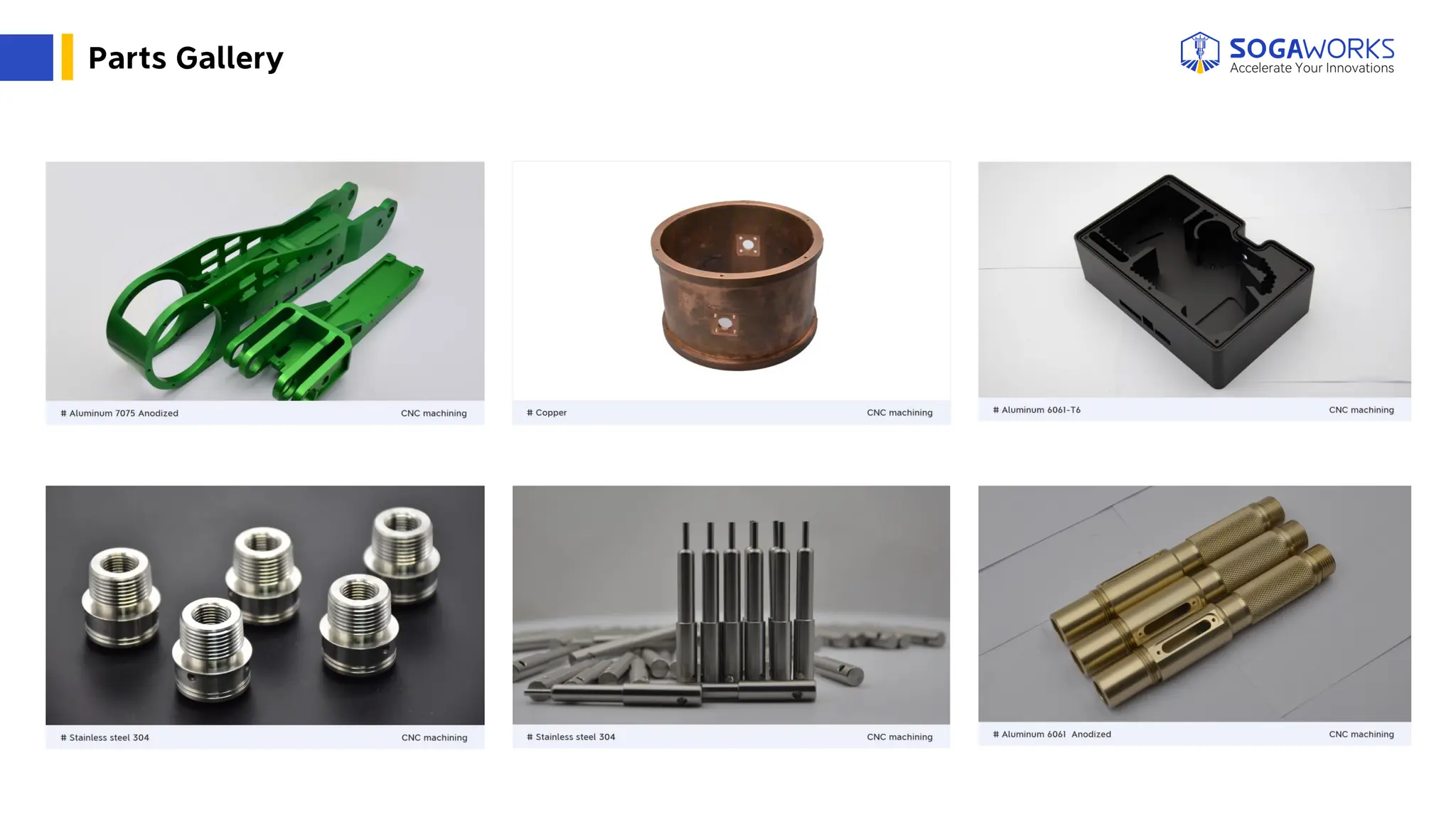

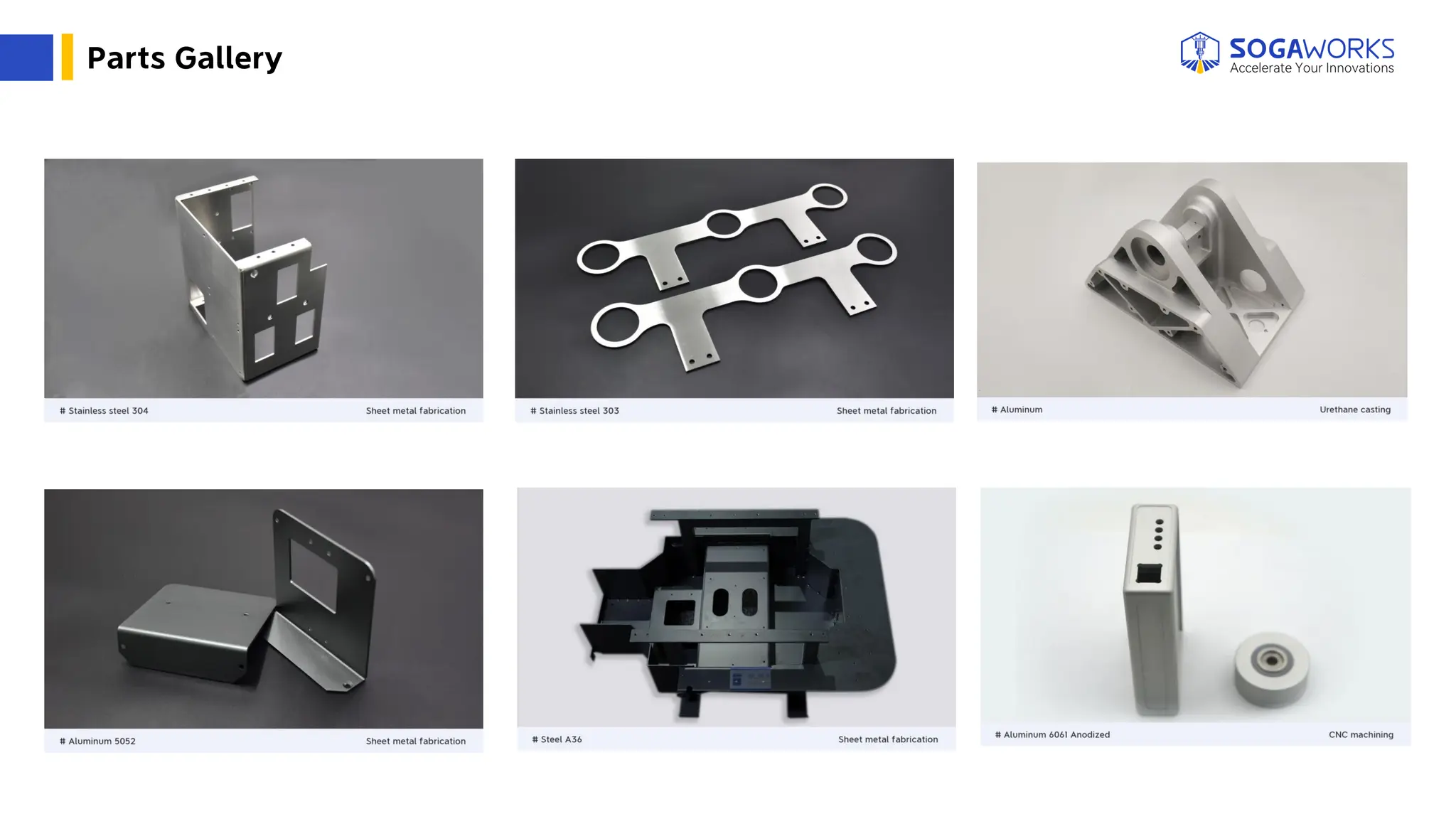

Sogaworks is a comprehensive on-demand manufacturing platform that offers services such as CNC machining, injection molding, sheet metal fabrication, and 3D printing to facilitate innovations for over 50,000 clients across 30+ countries since 2015. They have established a robust distributed supplier network and utilize advanced technologies like AI and IoT to ensure faster turnaround times, improved quality, and reduced costs. Their capabilities include a wide range of manufacturing processes backed by a quality control system, serving various industries including medical, aerospace, and consumer electronics.