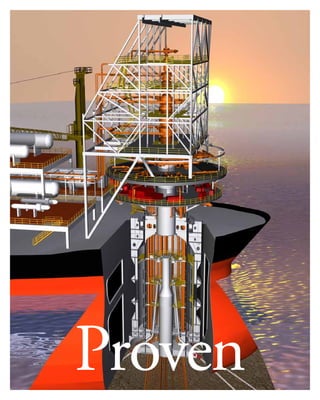

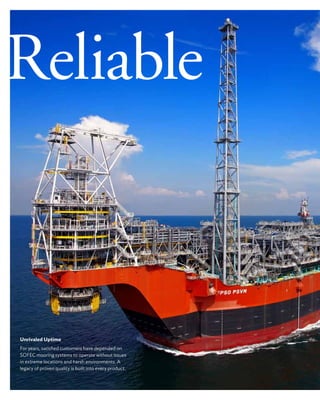

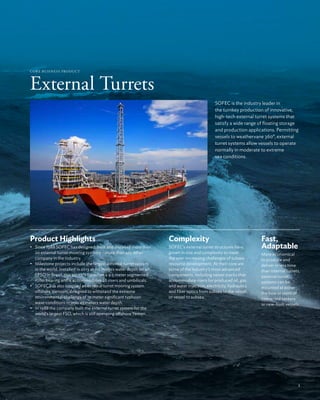

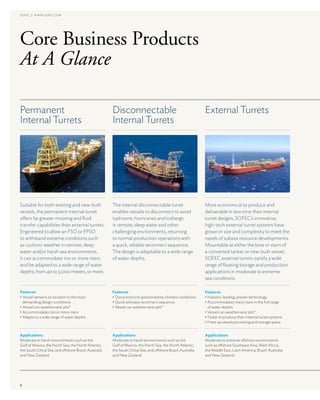

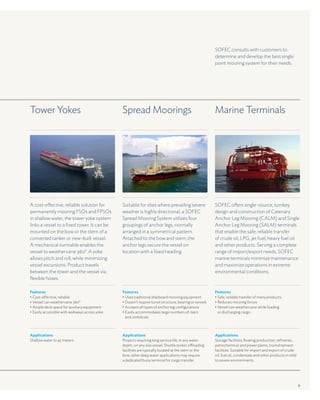

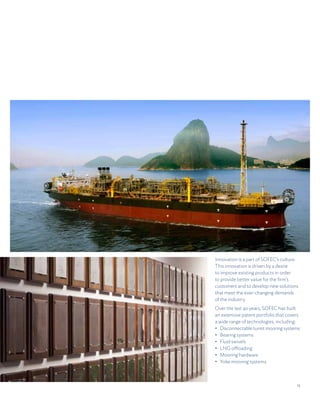

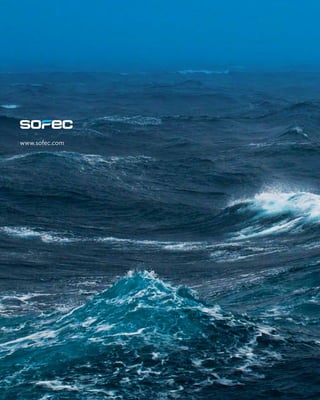

SOFEC is a global leader in developing single-point mooring solutions for floating production storage and offloading vessels (FPSOs) and floating storage and offloading vessels (FSOs). It offers turnkey development of mooring systems using proprietary, innovative technologies to suit a wide range of environments and water depths. SOFEC designs, manufactures, installs and services mooring systems including internal and external turrets, tower yokes, and marine terminals to reliably moor vessels in extreme locations and conditions.